PCB de-stacker loader simplifies double-sided PCB assembly with this versatile loader. It can load empty PCBs from stacks or partial assemblies from magazines, making it ideal for dual-sided assembly processes.

PCB de-stacker loader is an automated device consisting of automation equipment that integrates functions such as automatic PCB drilling, automatic wire feeding after drilling, and automatic stacking. It can be designed according to the processing requirements of PCB and can automatically drill holes in PCB boards, feed wires after drilling, and automatically stack boards during operation. It features high precision, fast speed, simple operation, and reliable performance.

PCB stacking machine is a type of automation equipment that separates the areas on PCB that require drilling from those that do not during processing, then stacks them together for the next process.

Features:

No PCB breakage guaranty beause of special gas circut design.

Destader loader and pallet conveyor compatible.

Use friendly membrane control panel.

Increase boad without interference.

By pass mode provided.

Adjustable transfer height.

Interface mounting brackets.

SMEMA compatible

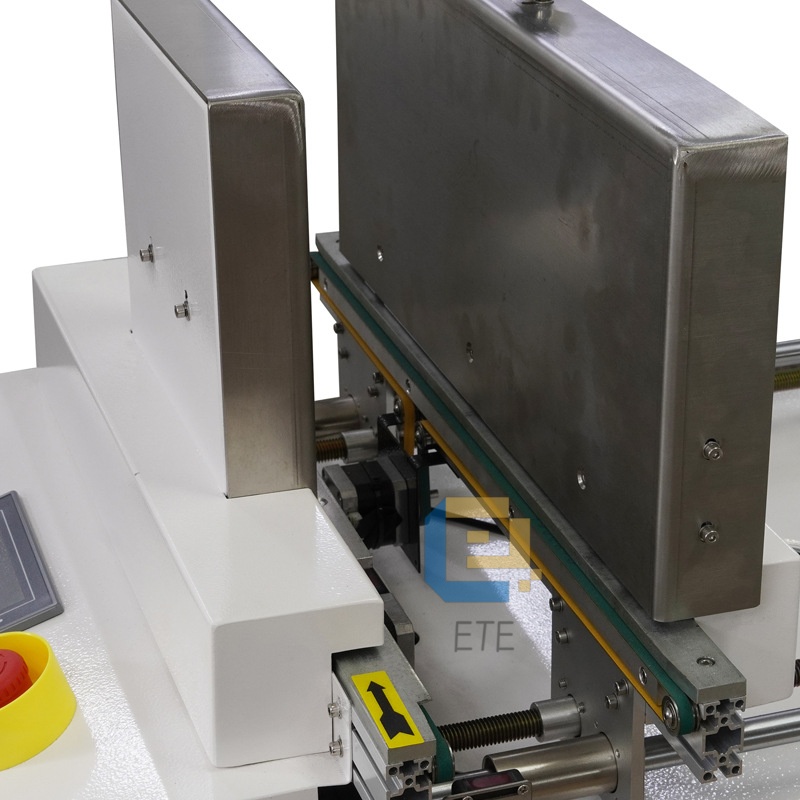

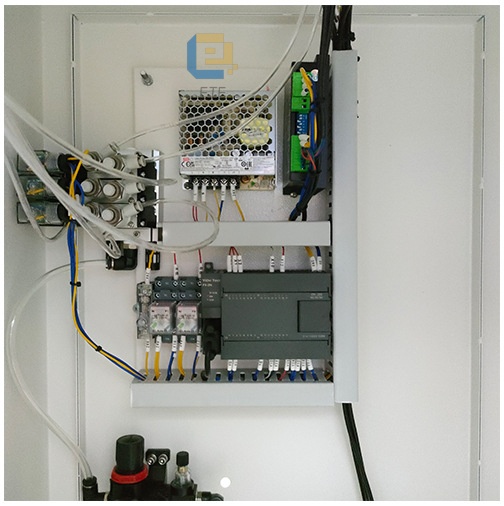

The PCB de-stacker loader, with its sturdy and durable aluminum alloy guide rails, ensures stability and durability while maintaining an aesthetic appeal. The microcomputer PLC control system guarantees reliable and consistent performance throughout operation. Users can easily interact with the equipment through the touch screen display, which features automatic fault diagnosis and facilitates seamless human-machine communication.

With multiple audio-visual alarms and touch screen prompts, the destacker loader provides efficient alerts and notifications during operation. Its ability to adjust the material wall height based on PCB thickness showcases the equipment’s adaptability to varying processing requirements. The humanized design prioritizes the protection of PCB boards, preventing damage and ultimately enhancing production output.

Moreover, the PCB loader is equipped with automatic bare board feeding and PASS dual functions, further optimizing workflow efficiency. By employing an automatic board dropping method, the equipment significantly reduces board loading time, improving overall operational efficiency. The utilization of electrical components from reputable brands ensures the reliability and longevity of the SMT loader.

Additionally, the standard SMEMA signal interface of the PCB de-stacker loader facilitates seamless integration with other equipment in the production line. Its compact footprint minimizes the required machine space, making it an ideal choice for facilities with limited space availability.

Specification

| Model | EDL-400 | |

| PCB Dimension(mm) | 50*50mm—-500*400mm | |

| PCB Thickness | 0.6-3.0mm | |

| Cycle Time | about 10s | |

| Transport Height | 910±20mm (or user specify) | |

| Transport Direction | L→R or R→L (easy adjustment) | |

| Machine dimension L*W*H(MM) | 600*800*1250 | |

| Machine weight | 180KG | |