The PCB cooling buffer conveyor is a crucial component in SMT production lines. It temporarily stores PCBs after reflow oven until they are adequately cooled. This ensures that the PCBs are at the optimal temperature before being conveyed to the next machine, AOI, for inspection of the soldering quality. The PCB cooling buffer conveyor plays a vital role in SMT production. Buffering and transporting circuit boards, enhancing production efficiency. Ultimately it minimizes downtime on the assembly line.

Features of PCB cooling buffer conveyor

- Thickened sheet metal structure with a rigid aluminum frame. Surface spray treatment, and black surface treatment.

- It uses a stable and reliable Panasonic PLC control system.

- Touchscreen display for easy operation, with automatic fault diagnosis and user-friendly interface.

- High-performance servo motor-driven lifting mechanism for Magazine elevation.

- Stores up to 20 PCBs with a 20mm spacing pitch.

- Adjustable spacing to accommodate different PCB widths.

- Monitor PCB storage quantity and time on the touchscreen.

- Automatically adjusts frame width to fit varying PCB widths.

- Multiple sound and light alarms with touchscreen alerts.

- Set shelf lifting step distance based on PCB thickness.

- Offers various functions: first in, first out; first in, last out; and pass-through capabilities. FIFO and FILO mode.

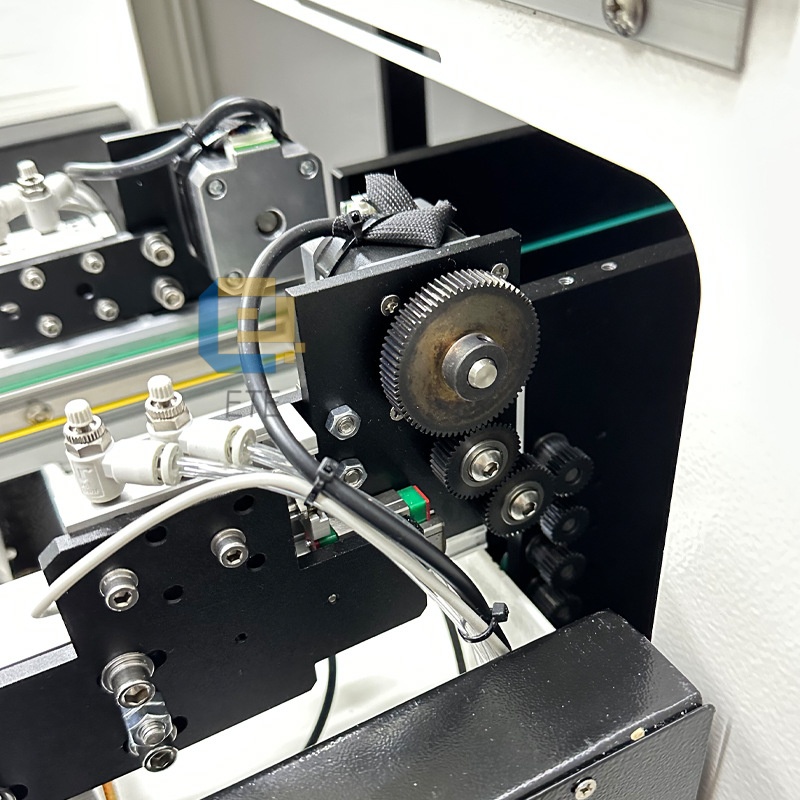

- Lifting system: ball screw + high carbon steel column, servo motor and driver for quiet, precise positioning.

- Width adjustment system: stepper motor + ball screw, screen input board frame, automatic frame width adjustment.

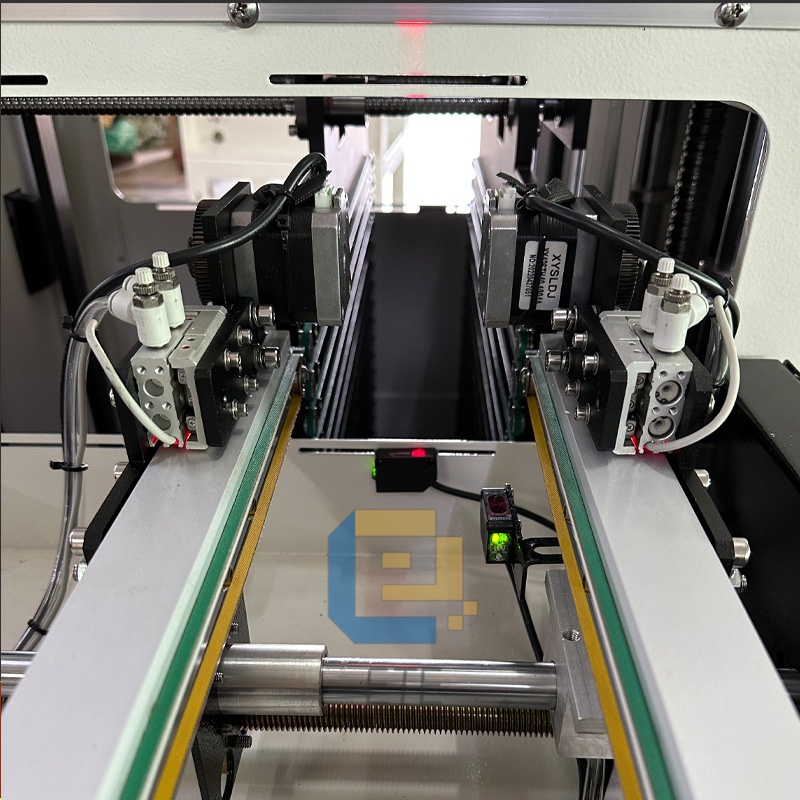

- Belt conveyor within the frame: precise gear alignment between motor gear and each belt gear to drive PCB transfer.

- Photoelectric sensing: multiple-angle placement of photoelectric switches to ensure precise and automated equipment actions.

Specification of PCB cooling buffer conveyor

| Model | ETB330 | |

| 1 | Control system | Panasonic PLC |

| 2 | PCB dimension (MM) | 450*(50-330) mm |

| 3 | PCB thickness | 0.6-3.0mm |

| Machine | ||

| 1 | Machine dimension L*W*H(MM) | 1050*810*1600MM |

| 2 | Machine weight | 280KG |

Welcome to our factory.