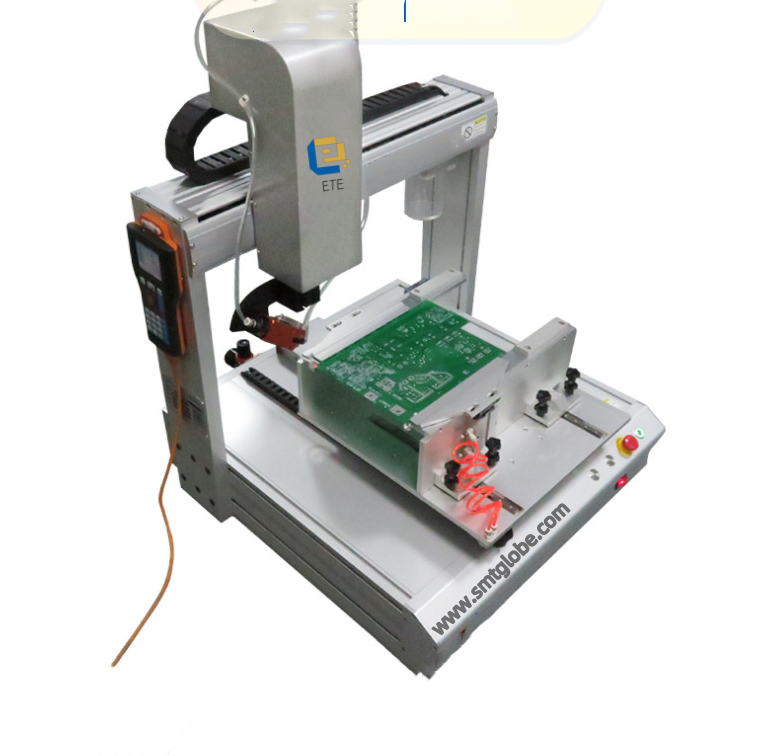

Our PCB Component Lead Cutter is suitable for the electronic industry, where PCB component leads need to be cut after soldering.

This machine is ideal for various applications, including PC power supplies, LED power supplies, industrial power supplies, chargers, control boards, and other areas where PCBA requires lead cutting. By replacing manual lead cutting processes, our cutter ensures stable cutting precision, reduces employee stress, and boosts production efficiency.

Key Features of PCB Component Lead Cutter

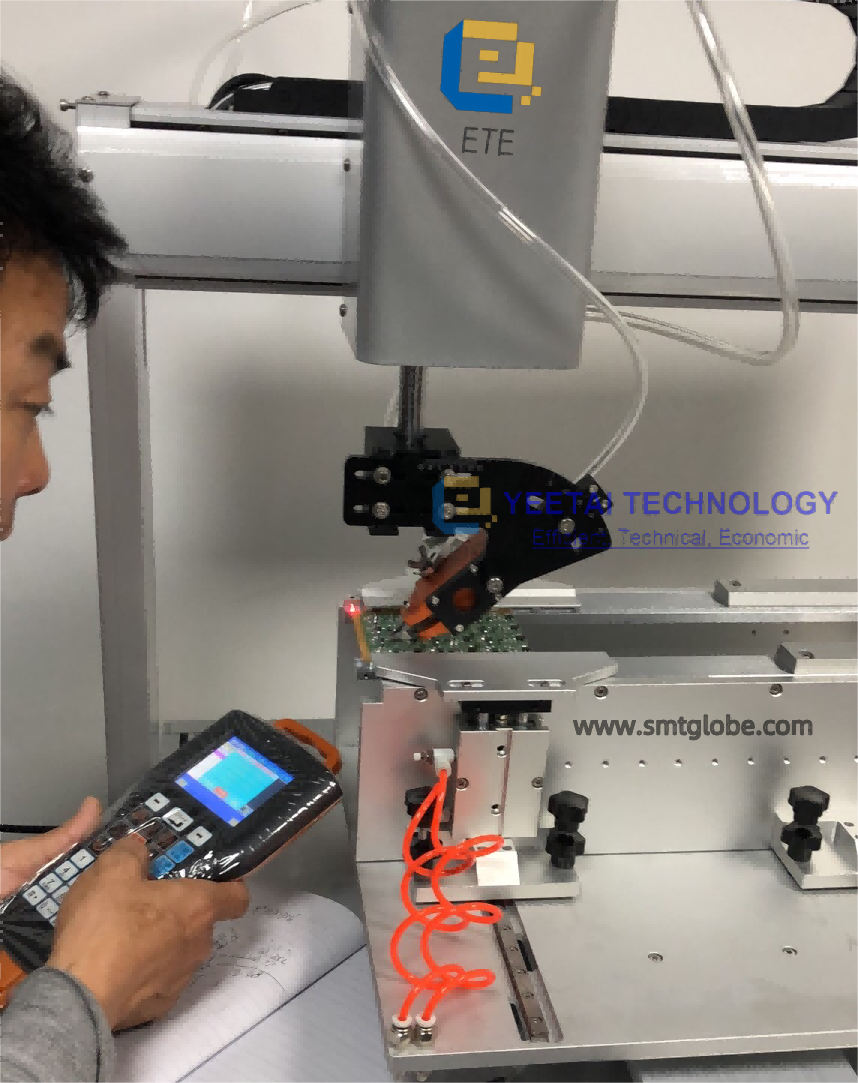

- User-Friendly Interface: The PCB Component Lead Cutter comes with a PCI control system and an independent human-machine interface. This design makes operation simple and straightforward.

- Efficient Document Storage: Equipped with a handheld box, the cutter can store over a thousand processing documents, each containing up to 8000 instructions. Users can easily access and execute previously saved documents without reprogramming.

- Quick Loading and Unloading: The machine allows manual switching of PCBAs from left to right for faster loading and unloading. It features a one-button “start” activation through fiber optic sensing, streamlining the cutting process.

- Labor Efficiency: Our cutting machine alleviates pressure on employees by automating lead cutting. This improvement enhances production line efficiency and addresses labor shortages in lead cutting roles.

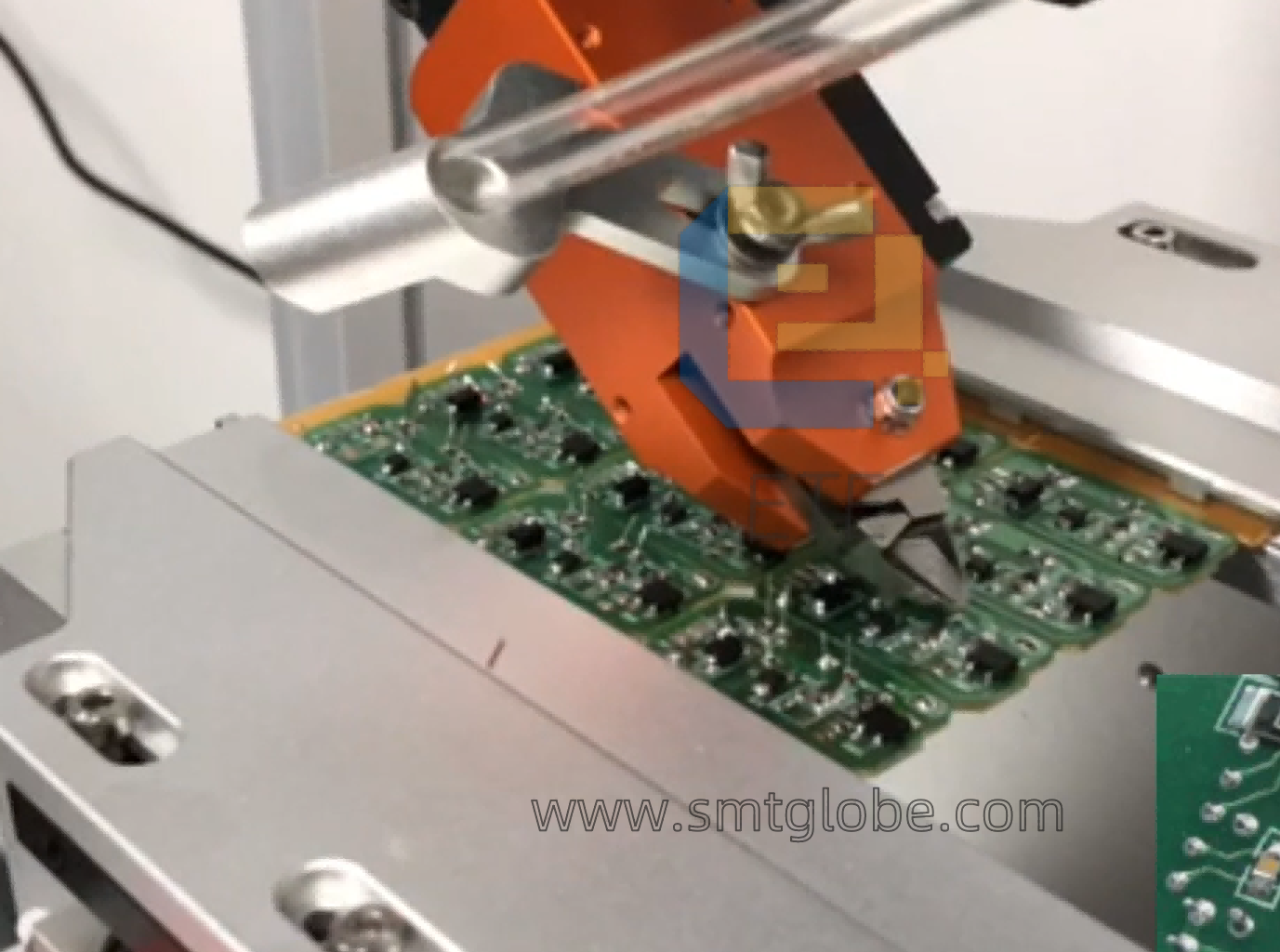

- Customizable Settings: Users can individually set the cutting speed and the quantity of single-point cuts. The machine utilizes high-precision closed-loop motors, which ensure accurate cutting trajectories in any movement path or angle. The adjustable cutting head offers versatility to meet diverse requirements.

Specification of PCB Component Lead Cutter

| Model | EF-630 | EF-A630S | |

| Machine size | 700x720x900mm | ||

| Machine movement Stroke | X-axis | 400 | |

| Y-axis | 320 | ||

| Z-axis | 100 | ||

| R-axis | 360° | ||

| U-axis | 90°(manual) | ||

| PCBA Size Range | 20x50mm~200x360mm(Optional 280x380mm) | ||

| PCBA part and wire height | 110mm(Other sizes optional) | ||

| Origin direction | Left (optionally right) (Flow: left origin: right → left; right origin: left → right; | ||

| Repeat Positioning Accuracy(mm) | Synchronous belt drive: 0.02-0.04 | Screw drive:0.01-0.02 | |

| load | Working load (bench top bearing) | 5kg | 8kg |

| Tool load (Z-bearing subjected) | 3kg | 5kg | |

| Drive Modes | Synchronous belt + guide rail (imported) | Grinding screw + guide rail (imported) | |

| Motion Platform Camera | Closed-loop stepper motor + stepper drive | Servo motor + servo drive | |

| Power supply | 220V AC/50Hz (Optional low voltage 110V power supply available) | ||

| Air Pressure | 0.6Mpa/6kg/cm2 | ||

| Rated Power | 750W(max) | 1500W(max) | |

| driving power | Voltage: 24V SDC | Voltage: 220V AC | |

| Current: 3.5A(Max)/Axis | Current: 6.5A(Max)/Axis | ||

| Pliers type | pneumatic scissors | ||

| Cutting capacity | Copper wire diameter Φ0.3mm or less (different wire diameter change different cutter) | ||

| Cutting efficiency | 120 points/minute or more | Above 150 points per minute | |

| Method of extracting part pins | Negative pressure suction vessel | ||

| Safety encoder | Production safety aids (optional) | ||

| MES system | Connection to production line for data management (optional) | ||

| Machine weight | 110kg | 120kg | |

Function Introduction

- User-Friendly Handheld Box: The handheld box features a high-resolution 320 x 240 color screen with a 3.2-inch LCD display. It offers a fully English operating interface, making it easy to learn and use.

- Versatile Graphic Elements: The system includes a variety of graphic elements such as running points, straight lines, multi-segment lines, three-dimensional arcs (space arcs), circles, runways, distances, coatings, automatic fillets, and irregular three-dimensional spline curves. It also provides rich manual teaching functions and a graphic preview capability.

- Conditional Jump and Rotation: The device supports conditional jumps and allows for double mark point rotation, enhancing its flexibility during operation.

- Skip Selection Function: Users can select multiple discontinuous instructions simultaneously, streamlining the editing process.

- Instruction Positioning: The system enables users to move edited instructions to target positions easily.

- Breakpoint Execution: With the breakpoint execution function, users can execute commands starting from a specified point, allowing for greater control during the cutting process.

- Advanced Editing Features: The system offers area array copy, offset operations, batch editing, single-step operation, and I/O input/output functions, providing a comprehensive suite of tools for efficient operation.

In summary, the PCB Component Lead Cutter helps SMT factories enhance production efficiency, reduce labor stress, and streamline the lead cutting process. Embrace automation and precision with our innovative lead cutter for all your PCB assembly needs.

If you need other solutions, we are here to help.

PCB Component Lead Cutter EF-630

PCB lead cutting machine