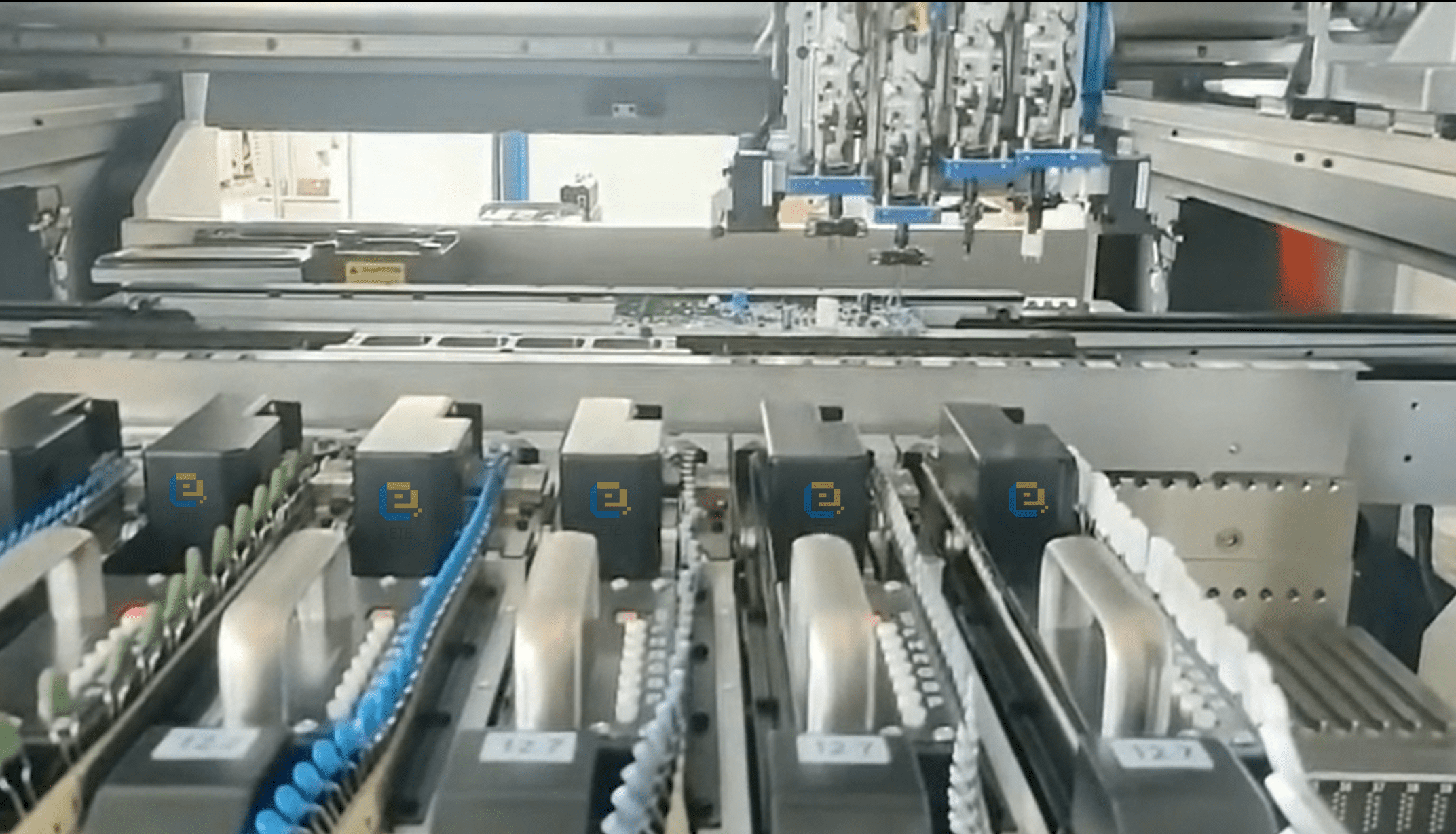

The Panasonic Radial Tape Feeder ETE-RT01 is a great equipment in the automation of through-hole component handling. This innovative feeder provides enhanced capabilities for feeding through-hole components to Panasonic SMT machine or odd form insertion machine. It is also compatible with Fuji, Yamaha, Siemens, and Samsung SMT machines or odd form insertion machines.

Equipped with automated feeding and cutting functions, the ETE-RT01 streamlines the process of handling components, offering seamless integration with various pick-and-place machines. Its compatibility with a wide range of machines and customizable feeding options makes it a versatile solution for different production needs.

In summary, the ETE-RT01 Panasonic Radial Tape Feeder offers precision, flexibility, and compatibility with various pick-and-place machines, making it an indispensable asset for PCB assembly companies seeking to enhance their automation capabilities and improve overall efficiency in through-hole component handling.

Features

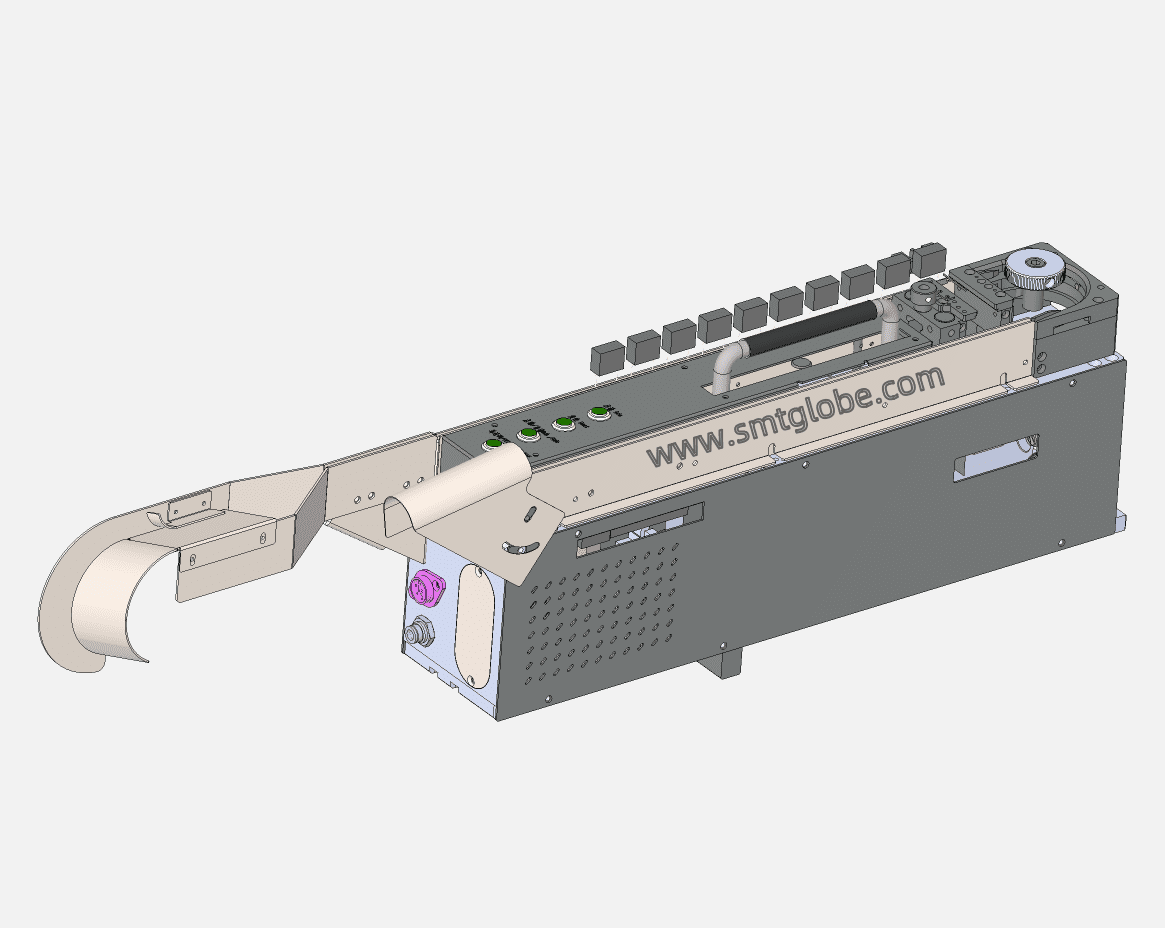

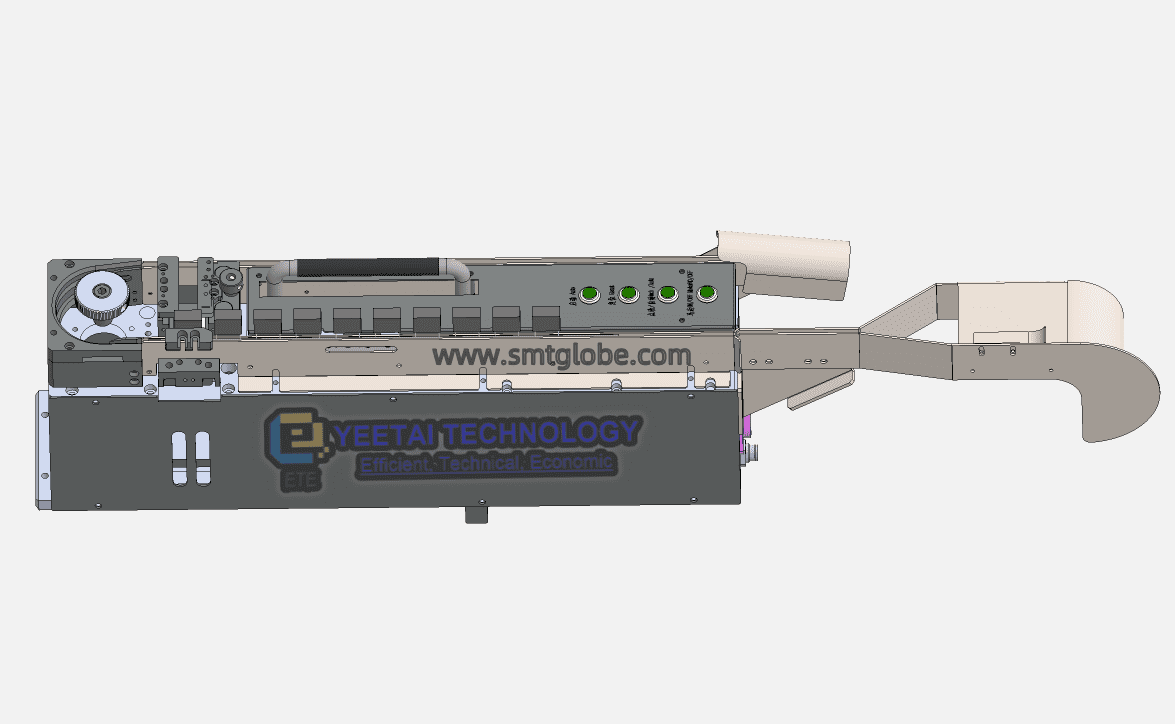

1.Radial component feeder E-RT01 has versatile functions of feeding and cutting.

2.The feeder features compact footprint, remote control, and rapid operation.

3.It supports all kinds of components packed in radial tape.

4. Compatible with a wide range of SMT machines and odd form insertion machines from brands including Panasonic,Yamaha, and Samsung.

Specification

| Model | Panasonic Radial Tape Feeder | ETE-RT01 |

| Overall Dimension | Length x Width x Height | 720x92x165mm |

| Weight | 10Kg | |

| Applicable materials | Material Type | Electrolytic Capacitor, Y Capacitor, Square Capacitor, Terminal, Spring, Bending Resistor |

| Overall Dimension | 2x2x3-15x15x30mm | |

| Wire Diameter | Core 0.3-1.0mm | |

| Cutting Length | 3-6mm (length adjustable) | |

| Hole distance of tape | 12.7mm and 15mm (these two cannot be shared) | |

| Structural part | Feeding method | Radial tape-fed components |

| Feeding | Motor-driven two feeding wheels to feed the material | |

| Cutting function | Adopting imported materials, adjustable length of cutting feet. | |

| Shaping function | Replacement of different shaping molds according to the spacing of the feet. | |

| Bending function | 90° bending of components (optional) | |

| Material Positioning | Split piece | |

| Tape discharge | Transferred by the feed wheels to rotate (the tail can be selected to cut off) | |

| Electrical parts | Working voltage | 24V |

| Average current/peak current | 4A/6A | |

| Working air pressure | 0.4-0.6Mpa | |

| Operation method | Push button operation | |

| Machine connection | 8-pole ø16mm aviation plug | |

| Communication mode | Support IO communication or no communication self-control | |

| Software control | PLC control | |

| Driving method | Stepping motor | |

| Motor system | Type 42/86 | |

| Maximum motor speed | 600rpm | |

| Feeding part | Action cycle time | 1S |

| Feed position adjustment | Y-direction adjustment by adjusting the dividing piece, X-direction adjustment of the limit block position | |

| Feeding accuracy | ±0.2mm | |

| Feeding with or without detection | Detected by front-end fiber optic, when there is no material for 3 consecutive times, an alarm will be issued. | |

| Inspection record | Feeding test | Achieve 1000 times of continuous feeding without any abnormality |

| Aging test | Continuous operation for 48 hours without any abnormality | |

| Service life | Service life 5 years | |

| Cutter life | 5 million times (cutter is consumable) |

Function

- The Panasonic Radial Tape Feeder automatically feeds, shapes, trims, bends, and processes electronic components on tape for efficient manufacturing.

- By mounting the Panasonic Radial Tape Feeder on a pick-and-place machine (or similar proprietary equipment), DIP component placement is achieved, saving on labor and reducing the need for transfer processes.

- Installing the feeder on a custom-shaped insertion machine enables automated insertion, with the option to customize feeders for different insertion machines.

- The feeder can be integrated with non-standard equipment for automated insertion, heat shrink tubing application, and component forming.

- Custom feeders for various machine types can be tailored to customer specifications, including options for tape cutting, component bending, and other customization features.

Features

- The Panasonic radial tape feeder streamlines the process by automatically feeding and cutting components, reducing manual labor and increasing efficiency in manufacturing operations.

- Seamlessly integrating with pick-and-place machines, the feeder enhances the automation of component placement, optimizing production processes.

- It provides precision handling of components during PCB assembly, guaranteeing high-quality results and minimizing errors.

- By offering enhanced efficiency and accuracy in through-hole technology, the feeder improves the overall quality of PCB assembly processes.

- Customizable feeding options for different component types allow the feeder to adapt to various production needs and requirements.

- The space-saving design of the Panasonic Radial Tape Feeder ensures a smaller footprint on the production line, maximizing workspace efficiency.

- The feeder enhances automation capabilities in production processes, increasing productivity and reducing manual intervention.

- Compatible with a wide range of pick-and-place machines, the feeder offers versatility and flexibility in manufacturing operations.

- By streamlining the PCB assembly process and eliminating the need for manual component handling, the Panasonic Radial Tape Feeder improves overall efficiency and productivity.