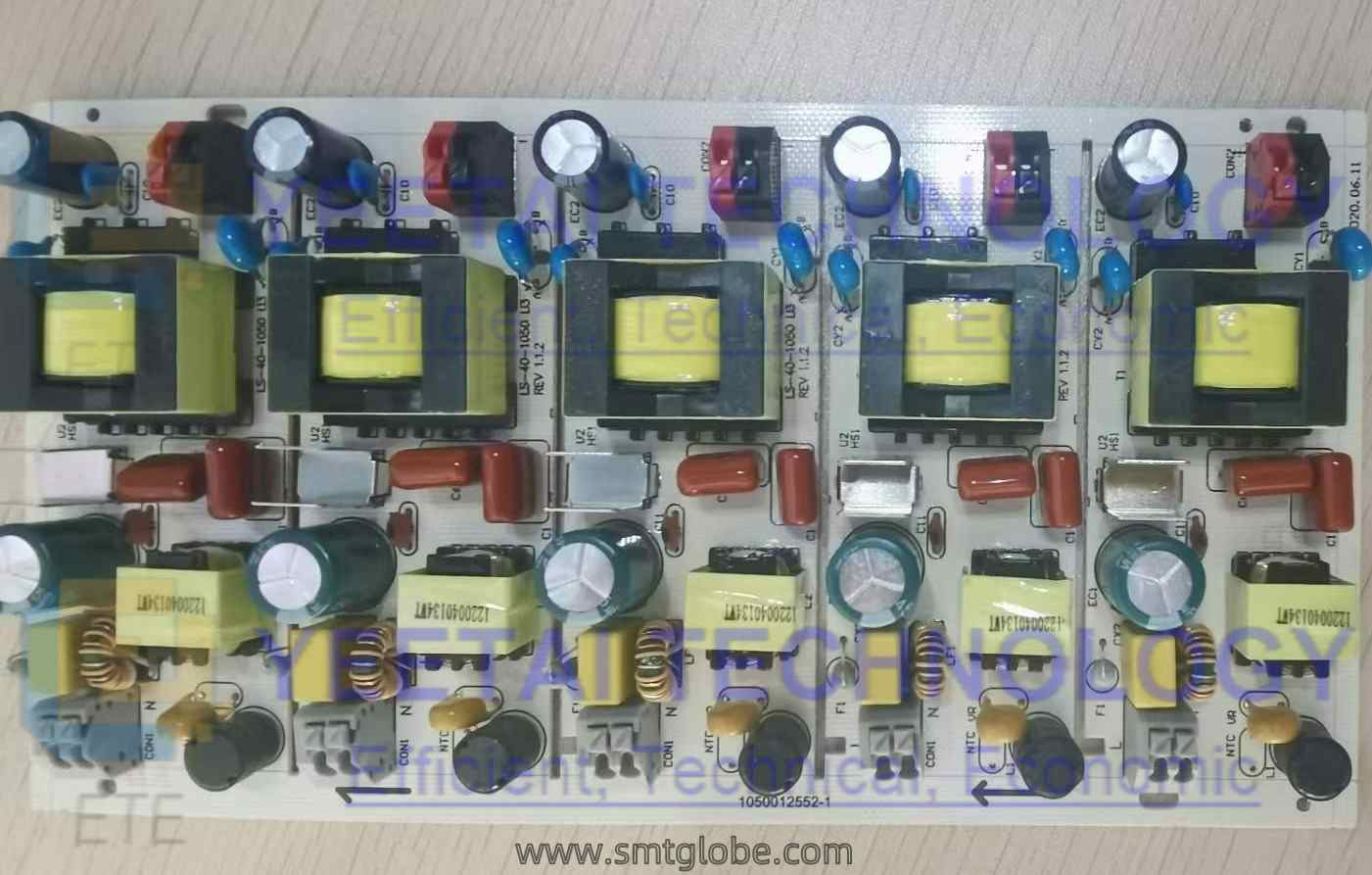

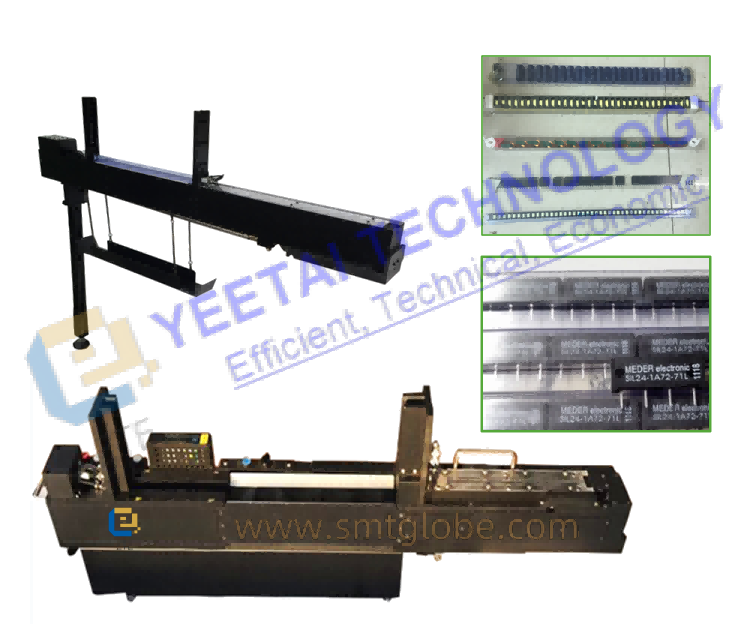

Odd form insertion machine provides automatic PCB assembly with special components. We specialize in manufacturing the EOIM and EEIM series of odd form insertion machines for automatic PCB assembly with special components to cater to various product applications.

The EOIM series odd form insertion machine is designed for inserting odd form components through modularized design. It utilizes SMT surface mount technology in conjunction with through-hole components to insert various odd form components rapidly and automatically, making it adaptable to various connectors, plugs, transformers, etc. The EOIM series equipment is equipped with multiple high-precision insertion heads and a versatile feeding system, allowing for simple and effective feeding methods for different odd form components. Flexibility, simplicity, efficiency, and stability are the key features of this series of machines.

The EEIM series odd form insertion machine is an economical model developed for small-batch, multi-variety production. When dealing with uncertain supplied components during product changeovers, the EIM series machines can easily import common parts, offering easy operation, low investment, and high returns.

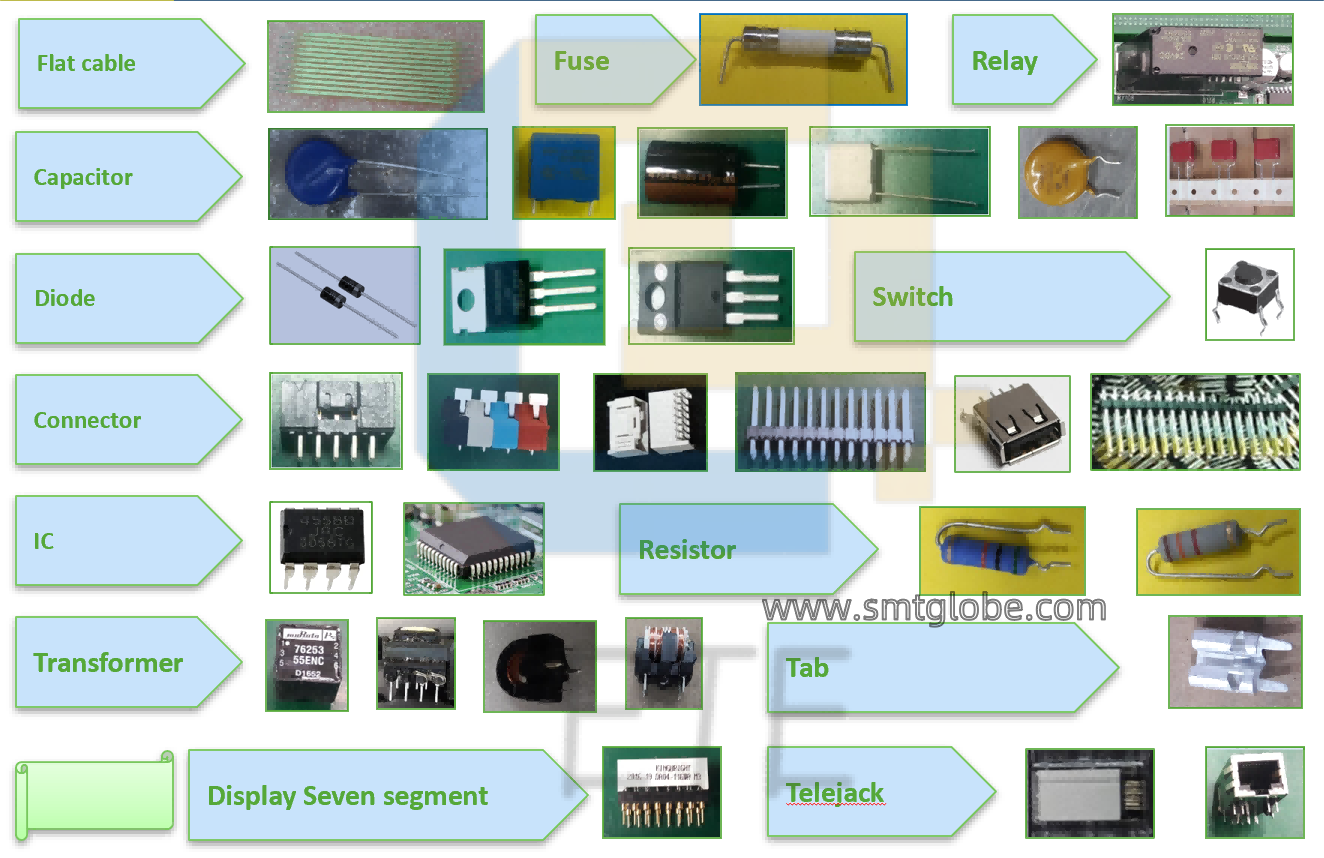

ETE’s Odd form insertion machines are capable of assembling a wide range of components onto PCBs. These machines can be equipped with various feeders to accommodate components of different packages, such as radial tape feeders, axial tape feeders, bowl feeders, tube feeders, tray feeders, and more. The working head of the machine can be customized with tooling to suit different components, ensuring high precision, high throughput, and reliability.

The odd form insertion machine produced by ETE has the following features:

- The programming software for the insertion machine can be installed on any computer outside the machine for programming.

- The program data and production data of the insertion machine (such as PCB size, component data, insertion coordinates, etc.) can be shared with other devices for reference.

- The equipment can intelligently calibrate errors through various precision algorithms and production data analysis to enhance equipment accuracy.

- By using standard CPK programs and accuracy verification processes, CPK test results above 1.0 can be obtained.

- Components can be identified and corrected using multiple algorithms for comprehensive analysis.

- The machine can be equipped with a suction nozzle station to automatically change the pickup head based on different materials.

- The machine can be equipped with a foot bending function to automatically bend the legs of long-legged components after insertion. The bending wire diameter should be <1.0mm, and the protruding leg length should be no less than 3mm (specific dimensions subject to final design specifications).

Specification

| Specification | Machine Model | ||||||

| EOIM-9S | EOIM-2SF | EEIM-8S | |||||

| No.of Insertion Heads | 6 | ||||||

| PCB Size (LxW) | 50×50 mm to 400×350 mm | 50×50 mm to 500×500 mm | 50×50 mm to 300×550 mm | ||||

| Carrier Size (LxW) | 400×350 mm | 500×500 mm | 350×550 mm | ||||

| PCB thickness | 0.6~2.0 mm | ||||||

| Max.PCB Weight | 2 Kg | 5 Kg | 2 Kg | ||||

| Max.Component height | 20 mm | 20 mm | 25mm | ||||

| Max.Component Width | 28 mm | 50 mm | |||||

| Speed / Component | 0.6s-3.0s | 0.7s~3.0s | 0.6s~3.0s | ||||

| Placement Accuracy | 3σ,±0.050 mm,CPK≥1.0 | ||||||

| Mark CCD(Top) | 1 | ||||||

| Vision System | Component CCD (Bottom) | 3×2 | 4 | 2 | |||

| Supporting Mechanism | Servo | ||||||

| Conveyor Type | Belt | Chain | Belt | ||||

| Conveyor PCB Mounting | Edge Clamping | ||||||

| Conveyor Section | 3 | ||||||

| Conveyor Adjusting | Auto | ||||||

| Conveyor Space (Upper/Lower) | 30 mm/20 mm | 25mm/20 mm | |||||

| Conveyor Height | 900±20 mm | 750±20 mm | |||||

| Max. Station Qty | Tape Feeder (SMT) | 12 | 6 | 4 | |||

| Tape Feeder (Al) | |||||||

| Tube Feeder | |||||||

| Bowl Feeder | 8 | 4 | |||||

| Tray Feeder | 1 | ||||||

| Operation System | Windows | ||||||

| Monitor Display (Operation Side) | 2 | 2 | |||||

| No.Of Door | 2 (Double Side) | 1(Single Side) | |||||

| Size(LxWxH) | 1290x1750x1990mm | 1290x1750x1840mm | 900x1760x1840mm | ||||

| Weight | 1730 Kg | 1650 Kg | 800 Kg | ||||

| Auto Nozzle Changer Unit | Option | ||||||

| Lead Clinching Unit | Optional | ||||||

| Programming | Vision Teaching System | ||||||

| AC Power | 220V 50/60HZ | ||||||

| Apparent power | 6KW | 4.5 KW | |||||

| Air Supply | 5.0~6.5 Kg/m | ||||||

| PCB Direction | L t o R (R to L ) | ||||||

| Insertion Direction | 0-360 Degree | ||||||

| Applicable Component | Connector,Switch,Socket Transformer Coils,Ports,Capacitors,Resistors Etc | ||||||

| SMEMA | Standard Configuration | ||||||

| MES Connection | |||||||

| Safety Grating (Door) | |||||||

| 2 Depends on different components. 3 Conveyor height of 750 and 900 are available ·4 No.of feeder depands on the combinatio 5 Conditional *6 Lead clinching unit will replace the PCB supporting mechanism 7 Only provided the original data format,the rest should be customer made | |||||||

Odd form insertion machine feeding system

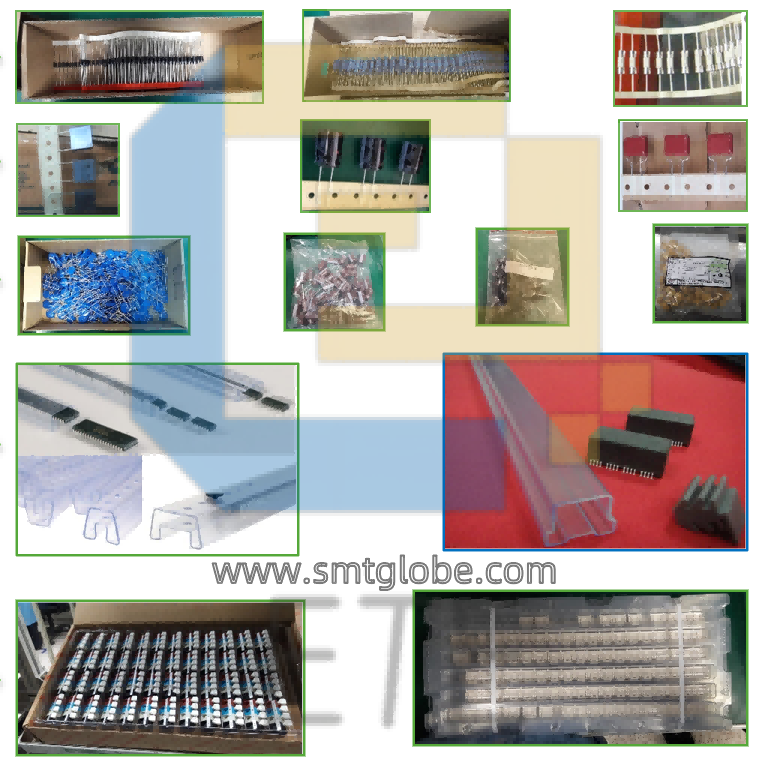

Based on the component package, the odd form insertion machine can be equipped with suitable feeders, allowing for flexible and interchangeable configurations. With experience in utilizing vibratory trays, direct vibratory feeders, part orientation, part forming, tape feeding, and cutting, we have a deep understanding of component characteristics and can effectively control and address irregular incoming materials. Blind insertion poses no challenge for us. Our efficient feeding system boasts broad applicability, fast loading speeds, high operational efficiency, and low maintenance costs.

The Radial Tape Feeder E201RT is specifically designed for tape-fed capacitors and can be used on both SMT and odd form insertion machines. It is suitable for components like capacitors and LEDs, offering versatility, quick loading speeds, high efficiency, and cost-effective maintenance. Customization options are available to meet diverse customer requirements.

The odd form insertion machine can be supplied with a Radial Tape 90 Feeder E207RT,which is tailored for single tape-fed materials, automatically forming a 90-degree bend. It is compatible with SMT and odd form insertion machines, suitable for components such as capacitors and LEDs. This feeder shares similar features with the E201RT model but with the added capability of customized 90-degree bends to suit specific needs.

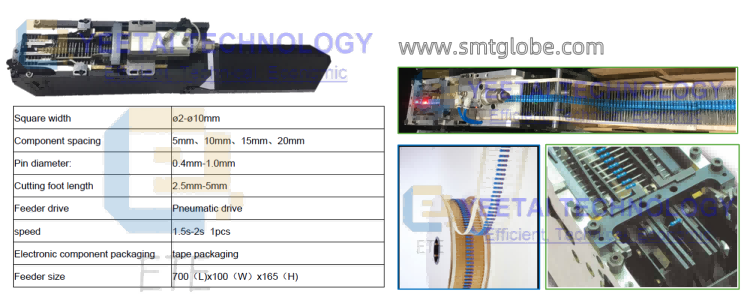

The odd form insertion machine can accommodate Axial Tape Feeder E202AT. This feeder is designed for axial tape feeding and can be used on both SMT and odd form insertion machines. It is suitable for components like resistors and fuses, offering versatility, fast loading speeds, high efficiency, and cost-effective maintenance. Customization options are available to cater to individual customer requirements.

We can also equip the odd form insertion machine with the tray feeder. It is a specialized feeding device developed for tray-fed materials. This product is designed to be used on odd form insertion machines and is suitable for components such as ICs, transformers, and coils. It boasts high efficiency, versatility, high safety, and stability. We offer customization options to tailor the feeder to meet individual customer requirements.

We can also install a tube feeder in the odd form insertion machine. The tube feeder ETF203 is specifically designed for tube-fed materials and can be used on both SMT and odd form insertion machines. It is suitable for components such as capacitors, transformers, relays, and VGA components. This feeder features strong versatility, fast loading speeds, high operational efficiency, and low maintenance costs. Customization options are available to meet diverse customer requirements.

The Tube Feeder ETF222 is designed for small tube-fed materials and can be used on both SMT and odd form insertion machines. It is suitable for components like ICs and small crystals. This feeder shares similar features with the Tube Feeder 203 but includes additional capabilities for lead cutting and forming. It offers strong versatility, fast loading speeds, high efficiency, and cost-effective maintenance. Customization options are available to cater to individual customer requirements.

If your components come in loose package, then we will design and equip bowl feeders in the odd form insertion machine. Most often, we have a types of bowl feeders, the Bowl Feeder E902BF and the Bowl Feeder E902BF.

The Bowl Feeder E902BF is a professional feeding device developed specifically for loose component materials. This product can be used on both odd form insertion machines and SMT pick and place machines. It is suitable for components such as connectors, terminals, small transformers, VGA components, headphone jacks, USB connectors, switches, HDMI ports, and more. The double-layer vibrating tray saves space and enhances feeding efficiency. Customization options are available to meet individual customer requirements. While the Bowl Feeder E902BF is designed specifically for loose LED and loose capacitor components. It can automatically differentiate between LEDs and capacitor polarities and adjust orientations accordingly. This feeder offers high cost-effectiveness, high safety, high stability, and strong versatility. Customization options are available to tailor the feeder to meet diverse customer requirements.

Insertion description

To cater to the diversity of odd-shaped components, we have designed the most suitable nozzles and grippers for the insertion head of the odd form insertion machine based on the shapes of different components, ensuring the high-speed operation of the insertion machine. With years of experience in electronic component equipment design, manufacturing, and on-site usage, we can maximize the grabbing and insertion rates of parts. Our professionalism, reliability, and peace of mind are the reasons why customers choose us.