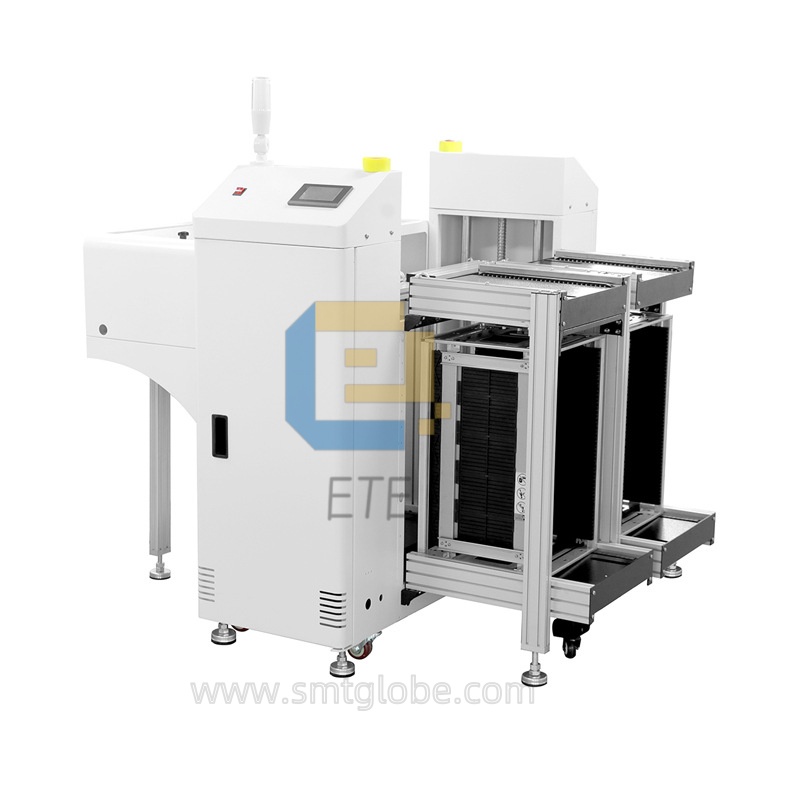

NG/OK Unloader: Automates the unloading process for your dual-track production line by pushing PCBs out of a magazine onto the downstream machine’s conveyor. This unloader features automatic magazine alignment and pneumatic clamping for seamless operations.

Operational Principle

Based on signal recognition, the NG OK Unloader automatically segregates NG and OK boards into two separate lifting and turning boxes. You caonline with the AOI machine. After the AOI inspection, the detection of good (OK) and defective (NG) boards results in different signals.These signals are then transmitted to the NG/OK board unloader. The NG/OK board unloader receives the signals from the AOI machine for classification. It automatically stores PCBs in either the OK or NG bins. For instance, when the AOI outputs an OK signal, NG/OK board unloader will enter the mobile pusher car and directly move into the OK lifting and lowering car bin. On the other hand, when the AOI outputs an NG signal, our NG OK unloader will pass the PCBs to anther lane.

Features:

External Structure: The NG OK Unloader features a 3mm thick sheet metal and aluminum frame structure with a corrugated white surface coating.

Equipped with a Panasonic PLC control system for stable and reliable operation.

User-friendly touch screen interface with automatic fault diagnosis function for easy human-machine interaction.

Multiple audiovisual alarms and prompts on the touch screen for enhanced operational awareness.

Adjustable lifting step distances based on PCB thickness.

Automatic counting function for convenient production statistics.

Humanized design to prevent PCB breakage and improve output efficiency.

Motorized pusher for transferring PCBs into the receiving bin.

Stepper motor pusher with customizable force and speed settings on the touch screen.

Pusher device equipped with Omron groove-type sensors for dual-end limit protection to prevent PCB damage.

Pushing distance for PCBs is adjustable.

OK boards loaded into the front bin, while NG boards are transferred to the rear bin after processing.

Dual-line differentiation for NG and OK boards.

SMEMA compatible

Specifications

| Model | Dimension (L*W*H.MM) | PCB size (MM) | Weight (KG) | Rack size (L*W*H.MM) |

| SBH250 | 1510*1530*1250 | 50*50-350×250 | 320KG | 355*320*563 |

| SBH330 | 1910*1630*1250 | 50*50-460×330 | 350KG | 460*400*563 |

| SBH390 | 2160*1760*1250 | 50*50-535×390 | 380KG | 535*460*563 |

| SBH460 | 2160*1900*1250 | 50×50-535×460 | 460KG | 535*530*563 |

| 1 | power supply | Single phase 220V |

| 2 | Starting power/no-load power | 500W |

| 3 | Lifting step distance | 10, 20, 30, 40, 50 (mm) can be set arbitrarily |

| 4 | compressed air | 5-6KG |

| 5 | fixed edge | 1\4 fixed distance 686mm |

| 6 | Transmission direction | left to right |

| 7 | Transmission height | 900±20mm |

| 8 | Step size selection | 1~5 steps (10mm\step distance) |

| 9 | Withstand voltage | AC terminal to ground 1500VAC, 1 minute |

| 10 | Usage environment | An environment free of corrosive gases and dust |

| 11 | Anti-interference | Voltage noise: 1000Vp-p, wave width 1us, 1 minute |

| 12 | Transfer, connect and push PCB board | Using stepper motor (42*48) |

| 13 | Lift points NG\OK PCB | The front and rear rails use Xinjie 750W large inertia servo motors |

| 14 | Lift drive | Xinjie 750W high-precision servo driver is used at the front and rear |

| 14 | Lifting transmission device | Imported anti-static 3.8mm wide belts are used at the front and rear, and seamless guide rails are used to prevent jamming and ensure smooth transportation. |

| 15 | NG line number | Automatically lifts and lowers into the NG storage frame (the storage frame can be entered and exited manually) |

| 16 | OK line number | Automatically enter the OK frame through the lifting platform (manual entry and exit of the storage frame) |

| 17 | PLC | Panasonic |

| 18 | touchscreen | Full color display control EA4.3 inch |

| 19 | Trough type photoelectric | Omron |

| 20 | Square Optoelectronics | Japan Panasonic CX442 |

| 21 | Lifting ball screw | High precision wear-resistant 25# |

| 22 | driver | Deco Intelligent Control Digital MT57 |

| 23 | plastic chain | 40B high wear-resistant houndstooth type |

| 24 | Lifting platform push plate motor | 4248 stepper motor |

| 25 | Transfer into the plate connection motor | Dual 4248 stepper motors |

| 26 | Guide rail fixed distance | 1. 4 guide rail fixed distance 686mm |

| 27 | Lift trolley drive | The double trolleys that individually control the lifting use 750W Xinjie servo |

| 28 | In and out of the material frame | The bottom is the OK frame and the top is the NG frame. Manual loading and unloading of the material frame. |

If you need other PCB board handling equipment, we can also help. Find them as below.