NG Buffer Conveyor: Streamlining Quality Control in SMT Manufacturing

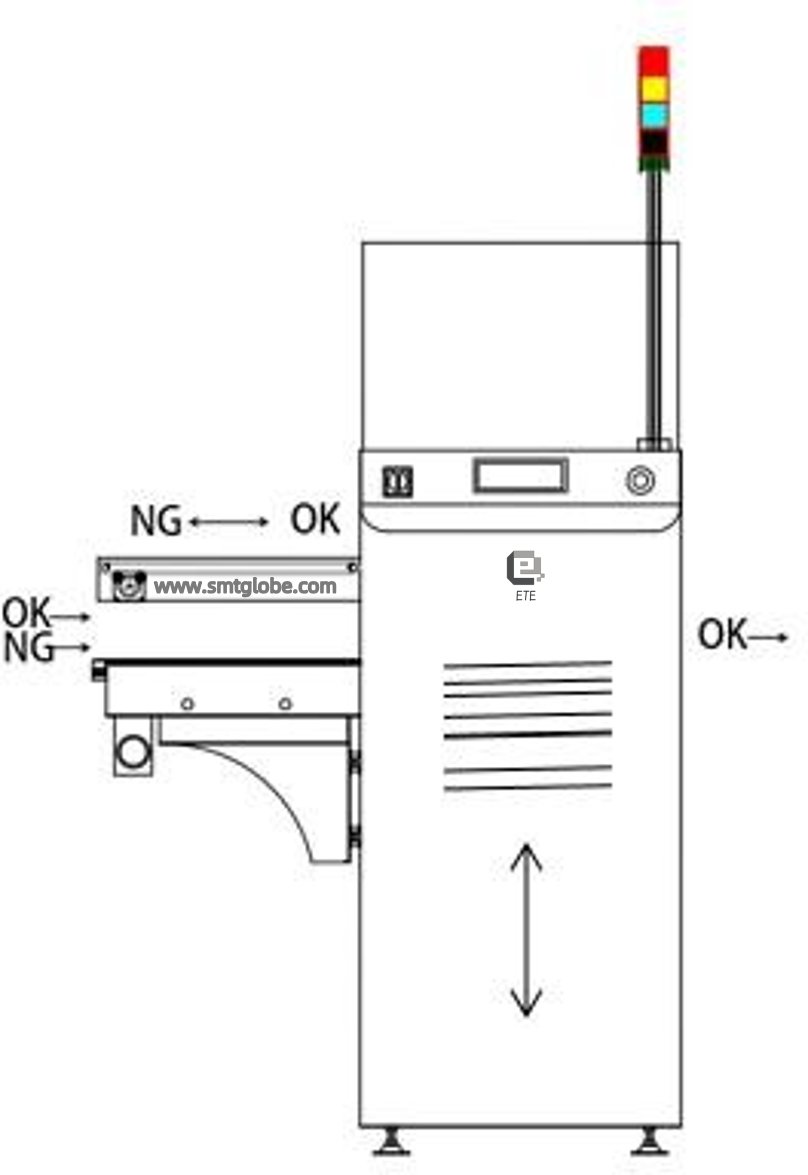

The NG Buffer Conveyor is an essential component in the backend of inspection systems such as Solder Paste Inspection (SPI) and Automated Optical Inspection (AOI). The conveyor automatically differentiates NG (Not Good) and OK boards based on signals from inspection devices (SPI, AOI). Thus, our conveyor ensures that only high-quality boards flow seamlessly to the next workstation. In contrast, NG boards are halted for further review and rectification. This critical role in quality control not only prevents defective PCBs from proceeding to subsequent production stages but also enhances overall product quality in SMT (Surface Mount Technology) factories. Additionally, the conveyor’s ability to store PCBs aids in balancing the operational speeds of machines across the production line.

Key Features of NG Buffer Conveyor

- Dual-Layer Lanes:

The conveyor features two-layer lanes. And it allows operators to easily review NG PCBs.

- Intuitive User Interface:

Equipped with user-friendly human-machine interface (HMI) keys. Operation is straightforward for all users.

- Precision Step Control:

Servo lifting technology guarantees precise steps for enhanced operational accuracy.

- Stable PLC Control:

The integration of programmable logic controller (PLC) technology. Multifunctional electrical circuits. Program design. They ensure reliable performance, facilitating smooth production line operation.

- High-Performance Sensors:

It uses advanced Sick sensors from Germany, ensuring dependable and efficient operation.

- Advanced Storage Functions:

Offers capabilities for first-in, first-out (FIFO), pass-through, and mixed storage, optimizing PCB handling.

- SMEMA Communication:

The standard SMEMA (Surface Mount Equipment Manufacturers Association) interface allows seamless connectivity with other automated machinery.

- PCB Protection System:

An innovative board protection system safeguards PCBs from damage. This will reduce potential process losses.

- Quality Transport Mechanism:

Imported bearings provide smooth and jam-free transport of PCBs.

- Soft Touch Control Panel:

Features a user-friendly ‘soft touch’ LED membrane control panel for easy operation.

- Multiple Operating Modes:

Supports various modes, including FIFO, Last In First Out (LIFO), and pass-through for flexible production needs.

- Width Adjustment:

Offers parallel and smooth width adjustment via a lead screw mechanism.

- Safety Features:

Its enclosed design provides a high level of safety for operators.

- Compact Footprint:

Designed with a small machine footprint. Suitable for space-constrained environments.

- SMEMA Compatibility:

Fully compatible with SMEMA standards for enhanced integration.

Specification of NG Buffer Conveyor

Transport height: 900mm ±20mm or specify

Transfer direction:L to R or specify R to L

Belt type: ESD belt (round belt)

Cycle time: 10 seconds approx.

Power supply: AC 110 Volts Or 220 Volts; Single Phase

Power consumption: 250VA max. or specify

Buffering capacity: 12 PCB or specify.

| Model | Dimension (L*W*H.MM) | PCB size(MM) | Weight(KG) | PCB Thickness |

| ENB250 | 1000*910*1600 | 50*50-330*250 | 160KG | 0.6~4 mm |

| ENB330 | 1200*990*1600 | 50*50-460*330 | 300KG | 0.6~4 mm |

Benefits of NG Buffer Conveyor

- Enhanced Quality Control: Significantly improves quality control processes, ultimately boosting product quality.

- Increased Efficiency: Prevents defective PCBs from progressing further in the production line, saving time and resources.

- Optimized Production Processes: Streamlines production operations while maintaining stringent quality standards for SMT factories.

In conclusion, the NG Buffer Conveyor is a critical investment for SMT manufacturers aiming to enhance their quality control protocols and improve operational efficiency. It ensures only the best products complete the manufacturing journey.

If you need other PCB board handling equipment, we can also help. Find them as below.