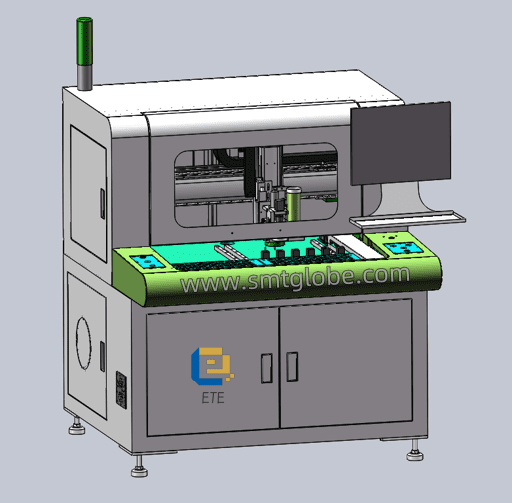

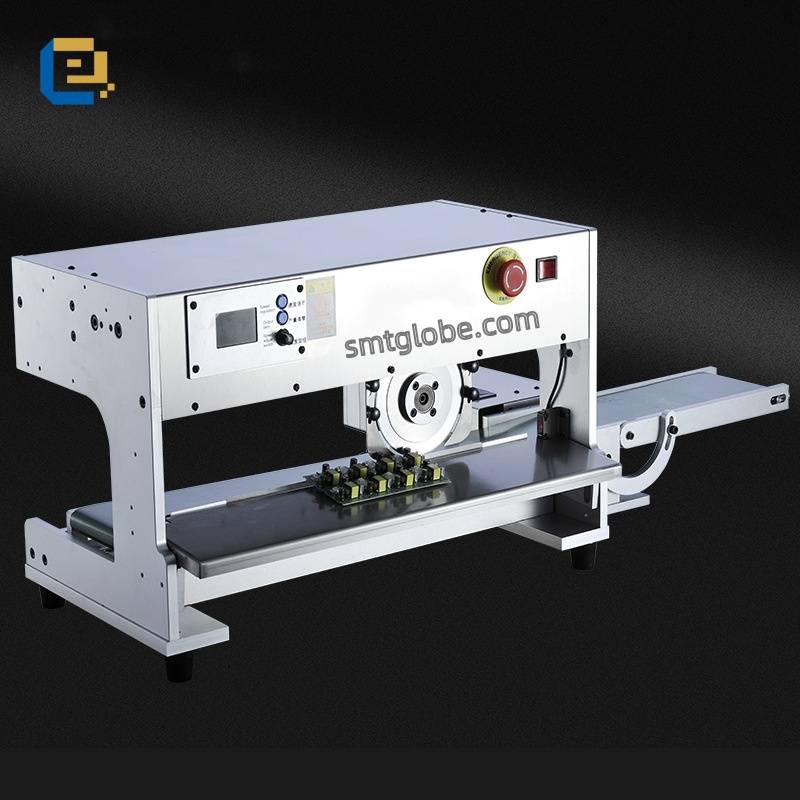

The Movable Blade PCB Depaneling Machine is an essential tool for efficiently separating V-CUT PCBs. To ensure safe and effective operation, it is crucial to follow specific guidelines and preparations. This article outlines important safety precautions, setup instructions, and operational preparations for using the machine correctly.

Important Safety Precautions

- Read the Instruction Manual Thoroughly

Before using the machine, it is essential to read the instruction manual in detail. Understanding the operating procedures will ensure your machine runs safely and smoothly. - Do Not Remove Protective Shields

Under no circumstances should the protective guards around the blades be removed. Doing so poses serious risks and increases the likelihood of accidents. - Intended Use

This machine is exclusively designed for separating PCBs that have been processed using V-CUT technology. Do not use it for any other purpose to avoid potential damage and hazards. - Dress Appropriately

When operating the machine, avoid wearing loose clothing, and ensure long hair is securely tied back. This helps prevent clothing or hair from being caught in the machinery.

Preparations Before Using the Movable Blade PCB Depaneling Machine

- Inspect the Package Contents

Upon receiving the machine, check the contents of the packaging box, which should include the following parts: the main unit, instruction manual, power cord, footswitch, and an allen wrench for adjustments. - Unpack the Machine

Carefully remove the machine from its packaging. Place it on a stable and flat workbench, and wipe off any anti-rust oil from the blades to ensure a clean working surface. - Ground the Machine

To prevent static electricity from damaging the components on the PCB, ensure the machine is properly grounded. If the grounding pin in the power outlet is effective, the machine will be adequately grounded when plugged in. - Adjust the Front Work Table

Secure the front work table to the machine using the two manual knob screws. Adjust the height of the front work table according to the height of the components on the PCB and lock it in place using the knob screws located beneath the table. - Connect the Footswitch

Plug the footswitch into the corresponding socket at the back of the machine. Once you have confirmed that the power voltage is correct, you can proceed to turn on the machine.

Conclusion

By adhering to these guidelines and preparations, operators can maximize the efficiency and safety of the Movable Blade PCB Depaneling Machine. Following the safety precautions and setup instructions will help ensure an optimal working environment and protect sensitive electronic components from damage. For best results, always maintain awareness of your surroundings and operate the machine according to the provided manual.

We are experienced at PCB depaneling. Know more PCB depaneling solutions in our website: www.smtglobe.com