In the electronics manufacturing industry, feeders (or supply devices) play a crucial role in SMT (Surface Mount Technology) assembly. The performance and functionality of feeders are significantly influenced by various professional knowledge and details. Recognizing and implementing best practices in design and operational processes can lead to successful output in the manufacturing process.Understanding Motor Knowledge in SMT Feeder Systems here.

Key Motor Knowledge in SMT Feeder Systems

- Symmetrical Component Method: This technique is used to analyze asymmetric operations in transformers and synchronous motors. The application relies on the linearity of the system, allowing the use of superposition to decompose asymmetrical three-phase systems into positive, negative, and zero sequence components.

3. Current and Voltage Transformers: Current transformers are designed to measure current and must never be open-circuited on the secondary side. In contrast, voltage transformers are used to measure voltage and should not be short-circuited on the secondary side.

4.Motor Functionality: Motors convert electrical energy into mechanical energy (or vice versa) or alter one level of AC voltage to another. From an energy conversion perspective, motors can be categorized into transformers, electric motors, and generators.

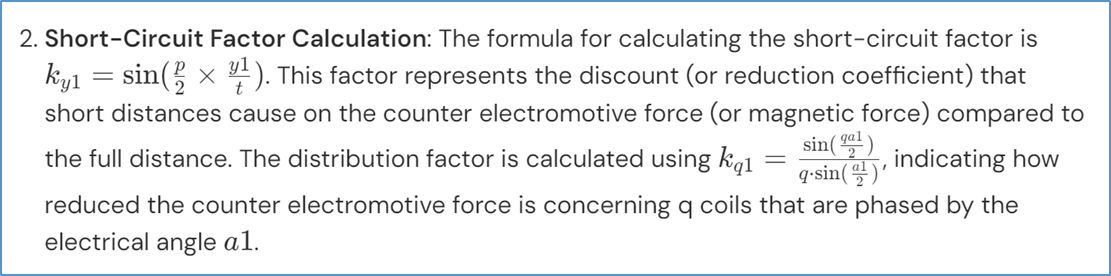

5.Slot Distance Electrical Angle: The calculation for the slot distance electrical angle a1a1 is given by a1=p×360°Za1=Zp×360°. This demonstrates that the slot distance electrical angle a1a1 is a multiple of pp for the corresponding electromagnetic angle.

6.Transformer Winding Clearance Principle: The principle states that winding must maintain constant magnetomotive force, as well as consistent active and reactive power, before and after any normalization.

7.Efficiency Curves of Transformers: The efficiency characteristic curve for transformers exhibits a maximum efficiency point, achieved when variable losses equal fixed losses.

8.Transformer Testing Protocols: Transformer no-load testing is performed on the low-voltage side at applied voltage, while short-circuit tests are conducted on the high-voltage side.

9.Conditions for Parallel Operation of Transformers: For parallel operation, conditions for no-load circulation are that the turns ratio must be identical and the connection group numbers should match.

10.Load Distribution Principles for Parallel Transformers: In parallel operations, the per unit value of transformer load current is inversely proportional to its short-circuit impedance. For optimal capacity utilization in parallel transformers, the per unit short-circuit impedance values must be equal and have matching impedance angles.

Conclusion

Understanding motor knowledge within SMT feeders is essential for enhancing operational efficiency and optimizing the performance of electronic assembly processes. Incorporating this knowledge during the design and operational stages can significantly diminish production issues and elevate output quality.

At YEETAI, we produce all kinds of feeder to upgrade SMT machines.