Manual Axial Lead Former: Efficient and Versatile Lead Bending Solution

Our Manual Axial Lead Former is a compact and lightweight machine designed for processing axial components such as resistors and diodes. This machine offers continuous feeding of component tapes and adjustable lead pitch and length. Crafted from high-quality materials and utilizing advanced sheet metal processes, this lead former ensures precision with high processing efficiency. It is perfect for a variety of production needs.

Machine specification:

Tool/Mold Material: Japan SKD11

Sheet Metal Process: High-temperature powder spraying/surface anode/hard chromium

Overall Dimension: L430xW300xH280mm

Weight: 13KG

Processing Efficiency: 30000-60000pcs/H

Power Supply: 110V/220V AC, 60HZ/50HZ

Size: Manual L430W300H280 m/m

Weight: Manual 8kg, Electric 24kg

Processing Capacity: 40000-80000 Pcs/H

Key Features of Manual Axial Lead Former

- Compact & Lightweight Design

The machine securely locks onto the workbench, providing a stable and efficient work environment. - Continuous Feeding Mechanism

Gears drive the continuous feeding of component tapes, streamlining the production process. - All-in-One Processing

The machine sequentially completes lead cutting, bending, and material retraction, enhancing production efficiency. - Customizable Specifications

Both the lead pitch and cut length are adjustable, allowing for flexibility in manufacturing different types of components.

How the Manual Axial Lead Former Operates

This machine uses gears to drive components forward. The cutting process employs a shearing mechanism to cut the leads, while molding is achieved through a top impact mold. This design allows for simultaneous cutting and molding, leading to increased efficiency.

How to Use the Manual Axial Lead Former

I. Preparation:

- Ensure that the area around the machine is clear of obstructions; remove any objects that may interfere with operation. Then, turn on the power to run the machine empty for testing.

- Adjust the wave-shaped feeding track to accommodate the width of the component being processed.

- Regulate the inner ratchet to enable versatility in machine operation.

- Set the outer ratchet to align the component molding width with process requirements.

- Adjust the molding sheet to ensure the correct molding shape while preventing damage to component pins.

- Conduct a trial production run with two components to verify compliance with process requirements. If adjustments are needed, refine the settings until requirements are met before commencing batch production.

II. Operating the Machine:

- Turn on the power and adjust the speed knob to the desired position.

- Manually place components into the wavy feeding track.

- Monitor the machine during operation; if components become misaligned in the feeding track, correct them immediately.

- Be attentive to the ratchet wheel; if any components become stuck, the machine will halt. Stop the machine to correct any misaligned components before resuming operation.

Additional Benefits

- Versatile Application: Designed for processing axial components such as resistors and diodes.

- Reliable Performance: Cutting and forming are completed in one operation, boosting production capacity and unaffected by power interruptions.

- Adjustable Parameters: Both the forming span and lead length are adjustable for varied production needs.

- Durable Tooling: Blades made from specialized tool steel ensure long-lasting performance.

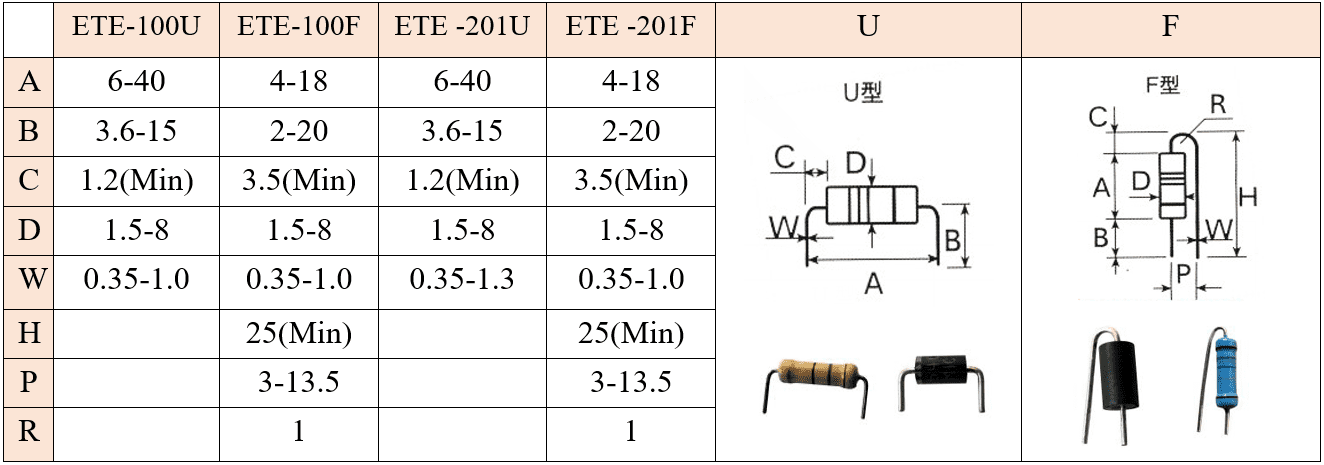

- Various Forming Capabilities: Capable of shaping U-type, US-type, and F-type components (note: the machine cannot perform both U and F types simultaneously).

- Cost-Effective Solution: Low operational costs make it suitable for large-scale production.

- Easy Setup and Adjustment: Streamlined adjustments facilitate batch production needs.

Conclusion

The Manual Axial Lead Former is an essential tool for manufacturers looking to efficiently produce high-quality axial components. Its robust design, user-friendly operation, and versatility make it a valuable addition to any production line. Interested in enhancing your production capabilities with the manual axial lead former?

Contact us today for more information or to request a quote!

If you need more component lead cutting and forming machines, you may read contents as below.