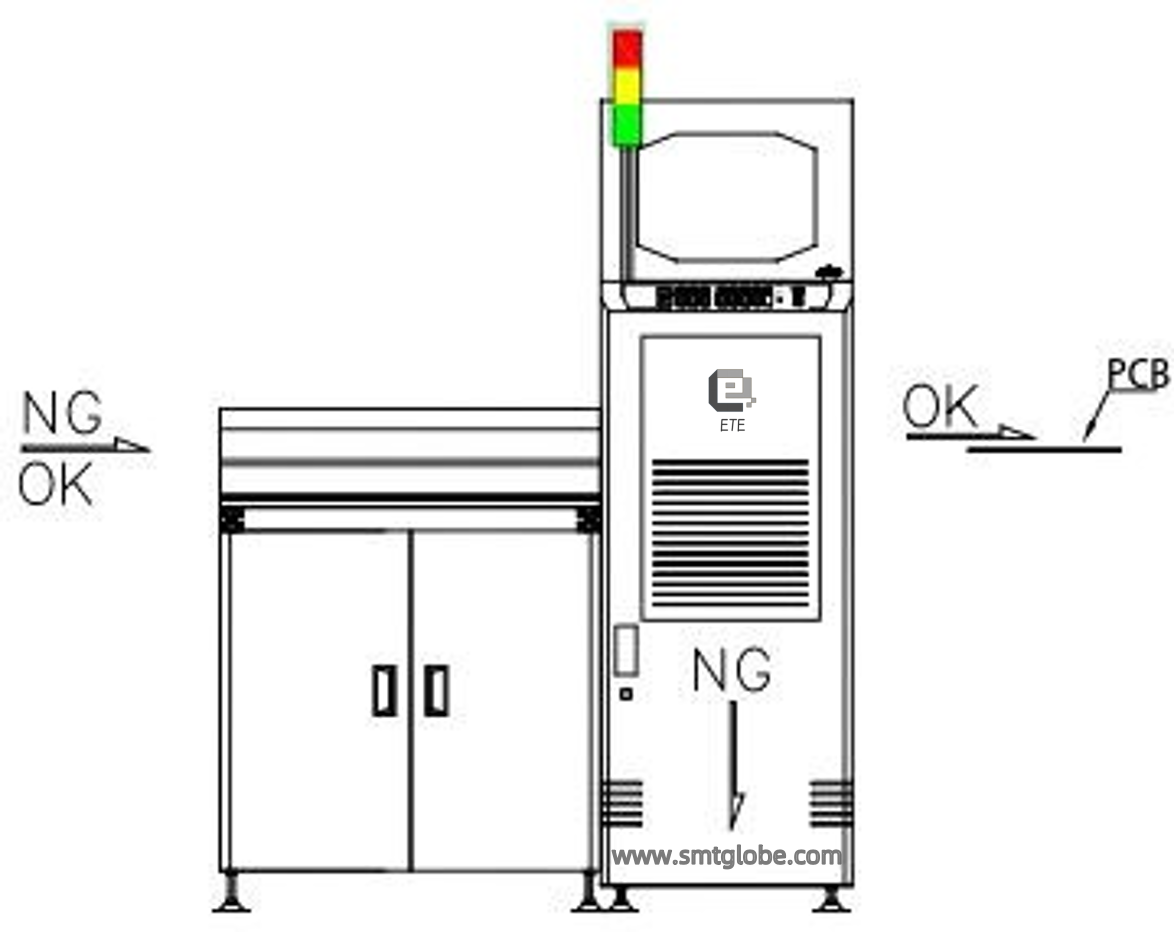

Magazine NG Buffer Conveyor: Optimizing Storage and Inspection Flow for PCBs

The Magazine NG Buffer Conveyor stores NG (Not Good) PCBA (Printed Circuit Board Assembly) after testing, such as Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI). It facilitates a seamless transition to higher-level inspection. This conveyor expertly accommodates a full magazine of PCBs. And it significantly enhances handling and inspection efficiency in manufacturing processes.

Key Features of Magazine NG Buffer Conveyor

Durable Construction: Constructed from a sealed aluminum alloy and sheet metal combination. You can clearly see the magazine’s operational status.

Intuitive User Interface: A user-friendly human-machine interface (HMI) integrates seamlessly into the NG Buffer Conveyor. Easy and intuitive operation for you.

Precision Magazine Positioning: The conveyor employs servo lifting technology for precise control of magazine positioning. Thus, it ensures performance during operation.

Stable PLC Control: Equipped with a programmable logic controller (PLC). With multifunctional electrical circuits, and robust program design. This conveyor ensures stable performance and smooth operation along the production line.

High-Performance Sensors: Advanced Sick sensors from Germany. Reliable and accurate operation throughout the handling process.

Capacity for 20 PCBs: The Magazine NG Buffer Conveyor can store up to 20 PCBs with a spacing of 25mm. It allows for efficient use of space and resources during production.

Advanced Storage Functions: Features multiple advanced storage capabilities, including first-in, first-out (FIFO), pass-through, and mixed storage. Flexible handling of PCBs.

SMEMA Communication Interface: Equipped with a standard SMEMA. Ensuring effortless connectivity with other automated equipment.

PCB Protection System: Incorporates a robust board protection system to safeguard PCBs from damage. Reducing potential process losses.

Smooth Transport Mechanism: Uses imported bearings to facilitate smooth PCB transport. Therefore, it ensures a jam-free operational experience.

Specification:

| Model | EMB-250 | EMB-330 | EMB-390 | EMB-460 |

| Dimension (L*W*H.MM) | 1150*1150*1205 | 1350*1350*1205 | 1550*1550*1205 | 1750x1750x1205 |

| PCB size(MM) | 50*50-330*250 | 50*50-445*330 | 50*50-530*390 | 50×50-530×460 |

| Weight(KG) | 160KG | 220KG | 280KG | 340KG |

| Magazine size(L*W*H.MM) | 355*320*563 | 460*400*563 | 535*460*563 | 535*530*563 |

| Transport height (mm) | 900±20(std) |

| Cycle time | 6.0 sec |

| Pitch | 10. 20. 30. 40mm selectable |

| Power supply | AC 110/220V±10V, 50/60HZ |

| Weight(KG) | 300 |

| Air Pressure & Air Consumption | 4-6bar, 10ltr/Min |

| PCB thickness | Min 0.4mm |

| PCB weight | Less than 1.5KG |

No.Of Magazine: Upper Conveyor: 1 Magazine; Lower Conveyor:2 Magazine

Indexing Pitch: 10.20.30.40mm Or Specify

Power Source: AC 110 Volts Or 220 Volts; Single Phase

Power Consumption: Max 250VA

Air Pressure & Air Consumption: 4-6bar, 15ltr/Min

Transport Height: 900±20MM

Transport Direction: From Left To Right Or Right To Left

Conclusion

The Magazine NG Buffer Conveyor is an essential asset for manufacturers seeking to enhance their PCB handling and inspection processes. With its durable construction, intuitive controls, and advanced features. It effectively improves efficiency and quality control, ultimately leading to a more streamlined manufacturing workflow.

If you need other PCB board handling equipment, we can also help. Find them as below.