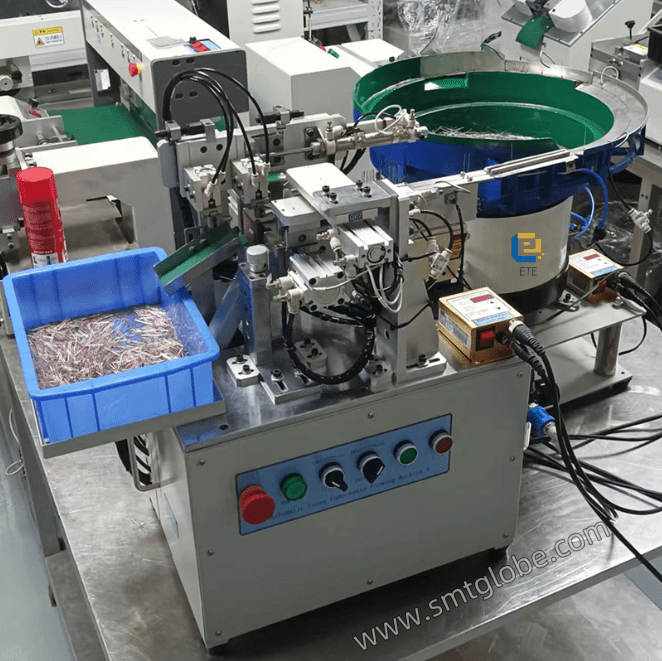

Our loose axial lead cutter former offers cutting and forming of axial components, such as resistor, diode, and fuse etc. It is controlled by a computer motherboard and features automatic feeding from a vibrating bowl. The machine comes with a robotic arm for material handling, shaping, polarity testing, orientation sorting, lead cutting, forming, and bending, all completed at different workstations.

Features of Loose Axial Lead Cutter Former

- Touchscreen human-machine interface for clear visibility and easy parameter setting.

- The machine employs left-right sliding seat shifting and motor displacement, effectively reducing noise and improving transmission accuracy.

- The entire machine adopts a compact integrated structure, making it easy to transport, and features a modular mold for convenient replacement.

- The forming method can be customized based on customer requirements for shape and size.

- It uses imported SMC cylinders and solenoid valves for durability, with forming molds and cutting tools made from high-quality Japanese SKD-11 material.

- Applicable Product: Fuses

Machine specification:

Model: ETE-309Q

Tool Material: Japan SKD11

Sheet Metal Process: High-temperature powder spraying/surface anode/hard chromium

Power Supply: 220VAC/50HZ

Air Supply: 5-7mpa

Overall Dimension: L1450xW950xH1500mm

Weight: 380Kg

Processing Efficiency: 3000-4500pcs/H

Power Supply Voltage: 220 (V)

Feeding Method: Fully automatic feeding by vibration plate and mechanical hand clamping Adjustable lead length (mm)

Processing Capacity: 3000-4500pcs/H Adjustable bending dimensions

Machine Configuration:

- Vibrating Bowl Automatic Feeding: Adjustable and controllable vibrating bowl speed, simple operation, and high-speed feeding.

- Automatic Material Sensing: Automatic sensing components with low material alarm.

- Automatic Clamping Device: Precise automatic material handling and feeding.

- Multi-Station Forming Mechanism: Automatic testing, automatic rejection of defective products, automatic lead cutting, automatic forming, with adjustable speed.

- Touchscreen Control System: Simple operation via touchscreen control.