Linking conveyor for coating: The Ideal Solution for Conformal Coating Lines

Our Linking conveyor for coating is specifically designed to enhance efficiency and precision in conformal coating processes. This essential piece of equipment integrates seamlessly into your production line, ensuring high-quality results for PCB manufacturing. Explore the key features and benefits for your operational needs.

Key Features of the Linking conveyor for coating

- Precision Linear Bearings and Dual Lead Screws:

Our conveyor utilizes precision linear bearings combined with dual lead screws, allowing for accurate and smooth width adjustments. This feature ensures optimal alignment and consistency during the coating process. - SMEMA Standard Communication:

Equipped with SMEMA (Surface Mount Equipment Manufacturers Association) standard communication capabilities, our conveyor can easily connect with other devices in your production line, facilitating seamless integration and improving overall workflow efficiency. - High-Precision Proximity Sensors:

The inclusion of high-precision proximity sensors enhances the sensitivity of the equipment, ensuring timely and accurate responses during operation. This feature not only increases usage rates but also minimizes downtime, maximizing productivity in your coating line. - Reserved Backboard Interface:

Our conveyor comes with a reserved backboard interface for quick and easy connection to additional equipment or backboards, providing flexibility for future expansions or upgrades in your manufacturing setup.

Specification

| Standard rail length | 900mm |

| PCB Width | 50-450mm |

| PCB Thickness | 0.6-5mm |

| PCB Transportation Speed | 700-2000/min |

| PCB Transportation Height | 900mm+-50 |

| Transportation direction | L→R or R→L |

| Chain Type | Extended Pin Chain |

| Conveyor Type | Chain Transfer |

| Rail fixed side | Front fixing |

| Power supply and power | AC220V 50/60Hz100W |

| Machine Size | 900(L)x900(W)x900(H) |

| PCB Clearance | 80mm/Up and down 80mm |

Why Choose Our Linking conveyor for coating?

- Efficiency Boost: Designed for optimal performance in conformal coating lines. Our Linking conveyor for coating minimizes errors and maximizes throughput.

- Quality Assurance: Achieve consistent coating results that meet industry standards, enhancing the quality and reliability of your PCBs.

- User-Friendly Design: The intuitive design of our conveyor makes it easy to operate and maintain, allowing your team to focus on production.

- Scalability: With its adaptable design and communication options, our machine can grow along with your business, accommodating future technological advancements or changes in production volume.

Conclusion

Investing in a high-quality Linking conveyor for coating is crucial for any business looking to improve its conformal coating processes. With features that prioritize efficiency, precision, and ease of integration, our conveyor is the perfect addition to your PCB manufacturing line.

For more information about our Linking conveyor for coating and how it can enhance your production capabilities, contact us today!

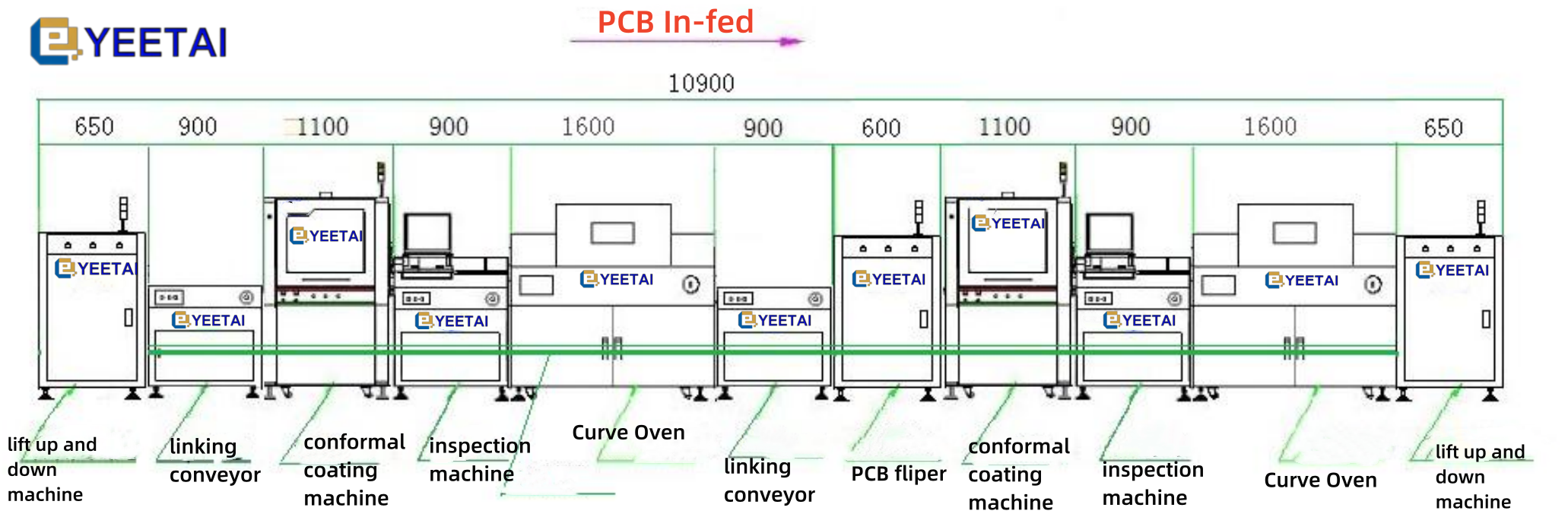

Conformal coating full line solution

We offer full line solutions of conformal coating process. You may read below pages.

Selective Conformal Coating Machine

Full conformal coating machine