Our LED PCB Depaneling Machine offers low-pressure and high precise cutting for LED panel.The LED PCB separator is a good helper for SMT factory.

Applicable Cutting: The LED PCB Depaneling Machine is designed to cut LED aluminum substrates ranging in thickness from 0.2mm to 5mm. If you have unique PCBA requirements, feel free to reach out to us for customized machine solutions tailored to meet your specific needs.

Features:

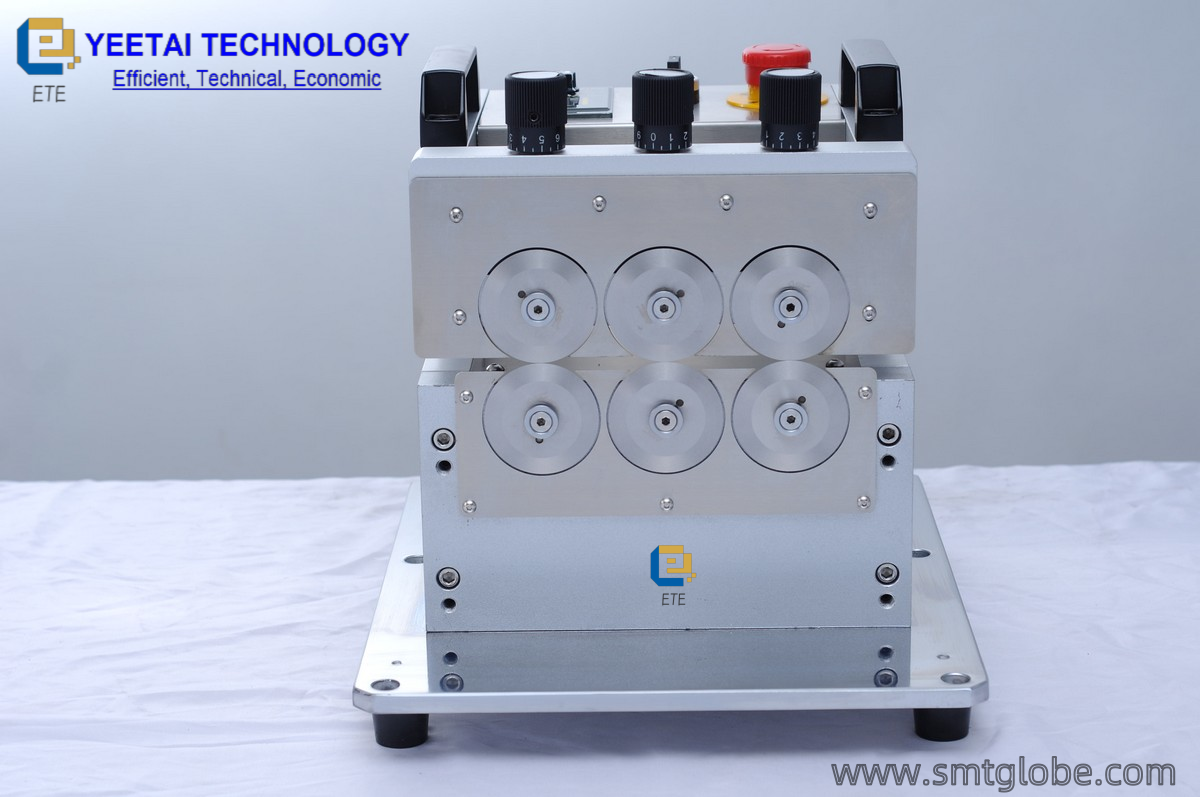

- The entire cutting process includes three stages. The A group of blades first cuts 40% of the circuit board, then the B group of blades rolls over the groove cut by the A blades. In this case, the LED PCB Depaneling Machine completes an additional 40% of the cutting, and finally, the C group of blades cuts the remaining 20% and polishes. As a result, cutting process cut down more than 80%. The segmented circuit board has smooth and flat edges, a very flat surface, and no warping. It is currently the only machine on the market that can guarantee that the aluminum substrate does not deform after cutting.

- Due to multiple cutting, the cutting process is very stable, greatly improving the positioning ability of the V-CUT groove. Besides, the narrow V-CUT grooves prevents PCB jumping out from the guide blade. Thus it reduces defective products.

- Small cutting force is employed to enhance the durability of the blades, leading to a blade lifespan that can surpass one year.

- All cutting blades undergo calibration using a dual-frequency laser interferometer to guarantee that the rear blade can maintain precise cutting within the groove created by the front blade. The blade tip remains stable within a fluctuation of no more than 0.02mm, ensuring exceptional cutting quality.

- The LED PCB Depaneling Machine is designed for easy operation and high speed performance.

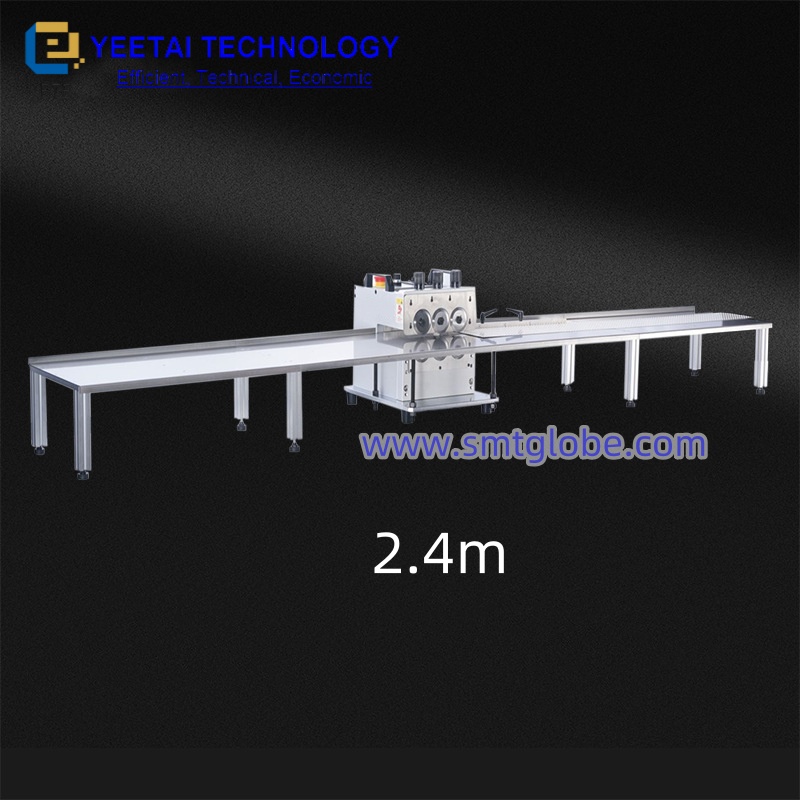

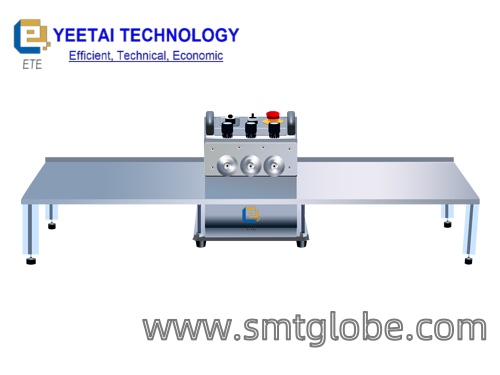

- The machine features a stainless steel platform with the option of a laser calibration positioning function at either 1.2 meters or 2.4 meters.

- Both the upper and lower circular blades are adjustable to accommodate various cutting requirements.

- The LED PCB Depaneling Machine is capable of handling cutting boards of different widths with ease.

- The X and Y axes can be adjusted to achieve the highest level of cutting accuracy.