The L type magazine unloader automatically receives printed circuit boards (PCBs) from a surface mount technology (SMT) production line. Its features unique L-shaped configuration. This makes it an ideal solution for optimizing space in compact SMT workshops. Discover how the L type magazine unloader can streamline your PCB handling processes efficiently and effectively. Know more at ETE www.smtglobe.com or info@smtglobe.com

The L type magazine unloader adopts a programmable controller system, featuring a sturdy structure and conveying track for a sleek appearance. The main function of the solder paste printer is to print solder paste on the PCB, followed by solder paste absorption. This simplifies the process in SMT production. Additionally, electronic products undergo a series of tests and evaluations when entering SMT production. The magazine unloaderc is ontrolled by PLC. It can automatically adjust the descent height and adapt to different working environments.

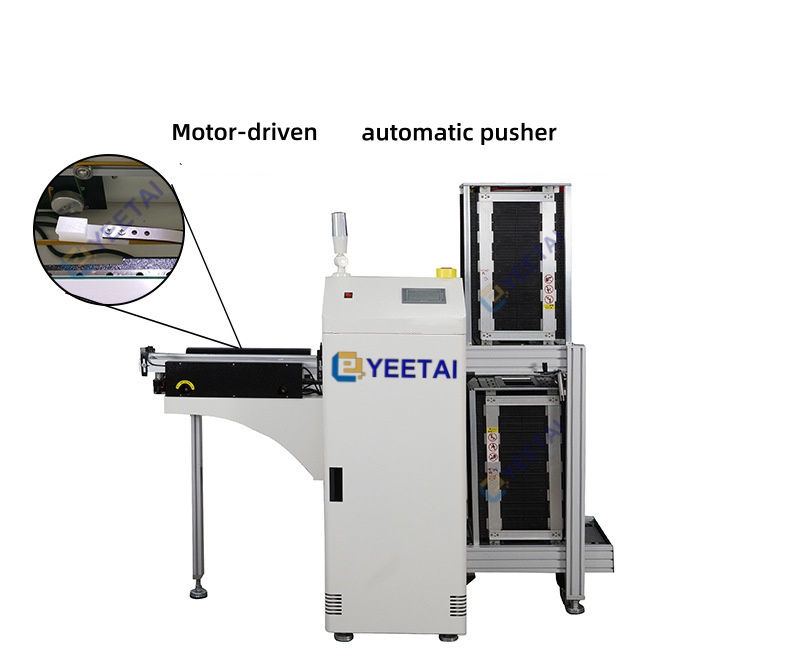

Features of L Type Magazine Unloader

- Robust External Structure: Constructed from high-quality sheet metal and an aluminum frame. Sleek white surface coating for a professional appearance and durability.

- Stable Microcomputer PLC Control System: Equipped with a microcomputer PLC control system. Stable and reliable operation for consistent performance.

- User-Friendly Touch Screen Display: The intuitive touch screen facilitates easy operation. And it features an automatic fault diagnosis function for quick troubleshooting.

- Audiovisual Alarms and Prompts: Multiple audiovisual alarms and prompts on the touch screen. It improves operational awareness, alerting operators to critical events.

- Adjustable Lifting Step Distances: The unloader allows for adjustable lifting step distances based on PCB thickness. Adapting to various PCB sizes.

- Automatic Counting Function: This feature provides convenient production statistics. Helping operators track output efficiently.

- Humanized Design: Designed to prevent PCB breakage. Improves output efficiency and minimizes the risk of damage during handling.

- Motorized Pusher for PCB Transfer: The unloader includes a motorized pusher that efficiently transfers PCBs into the receiving bin.

- Stepper Motor Pusher: The stepper motor pusher comes with adjustable force and speed settings. You can customize the handling of PCBs via the touch screen.

- Dual-End Limit Protection: The pusher device equipped with dual-end limit protection. It ensures safe handling and prevents PCB damage.

- Space-Saving Design: Specifically designed for workshops with limited space. the L Type Magazine Unloader optimizes functionality in constrained environments.

- Sturdy and Stable Construction: Featuring a robust and stable design. Ensuring reliable performance and longevity even under extended use.

- Intuitive Control Panel: The user-friendly ‘soft touch’ LED membrane control panel.

- Pneumatic Clamps for Precision Alignment: Pneumatic clamps facilitate precise alignment of magazines. Enhancing efficiency and accuracy during the unloading process.

- Regulated Pneumatic Pusher Pressure: The pressure of the pneumatic pusher is regulated for controlled and consistent handling of PCBs during unloading.

- High Throughput Capacity: With a high throughput capacity and short magazine change-over time. Our unloader maximizes productivity and minimizes downtime in production operations.

- SMEMA Compatibility: SMEMA compatible. Seamless integration with other equipment in the SMT production line. Enhancing automation and workflow efficiency.

Specifications

Transfer direction: L to R OR R to L

Time feed: 6 seconds Approx. Or specify.

Air supply& consumption: ≥6 bar,10 ltr/min max.

Power supply:110V /220V, 50 Hz/ 1 Ph, max 300VA

Indexing pitch: 10.20.30.40mm or specify.

| Model | Dimension (L*W*H.MM) | PCB size (MM) | Weight (KG) | Rack size (L*W*H.MM) |

| EULT250 | 1150*1150*1250 | 50*50-330*250 | 160KG | 355*320*563 |

| EULT330 | 1350*1350*1250 | 50*50-445*330 | 220KG | 460*400*563 |

| EULT390 | 1550*1550*1250 | 50*50-530*390 | 280KG | 535*460*563 |

| 1 | power supply | Single phase 220V |

| 2 | Starting power/no-load power | 105W |

| 3 | Lifting step distance | 10, 20, 30, 40, 50 (mm) can be set arbitrarily |

| 4 | compressed air | 5-6KG |

| 5 | fixed edge | Front fixed (rear fixed can be customized) |

| 6 | Transmission direction | Left to right (right to left can be customized) |

| 7 | Transmission height | 900±20mm |

| 8 | Step size selection | 1~5 steps (10mm step) |

| 9 | Withstand voltage | AC terminal to ground 1500VAC, 1 minute |

| 10 | Usage environment | An environment free of corrosive gases and dust |

| 11 | Anti-interference | Voltage noise: 1000Vp-p, wave width 1us, 1 minute |

| 12 | Push the PCB board driver under the connection | Using stepper motor (42*48) |

| 13 | PLC | Siemens (dedicated controller) |

| 14 | touchscreen | Samkoon4.3#smart touch screen |

If you need other PCB board handling equipment, we can also help. Find them as below.