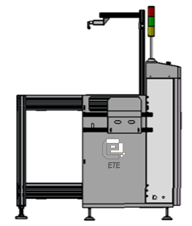

L Type Magazine Loader: Specifically designed for limited workshops. This loading machine optimizes the flow direction of PCBs, saving space while efficiently loading PCBs. It automatically transports PCBs into these machines on the SMT production line. The L type magazine loader communicates with these SMT machines through the SMEMA interface, enabling seamless online production. Its L-shaped design allows for space-efficient utilization in limited SMT workshops. And it enhances spatial efficiency.Furthermore, it helps SMT factories save labor costs with a fast ROI.

Specification

| Model | Dimension (L*W*H.MM) | PCB size(MM) | Weight(KG) | Rack size(L*W*H.MM) |

| ELL250 | 1150*1150*1250 | 50*50-330*250 | 160KG | 355*320*563 |

| ELL330 | 1350*1350*1250 | 50*50-445*330 | 220KG | 460*400*563 |

| ELL390 | 1550*1550*1250 | 50*50-530*390 | 280KG | 535*460*563 |

Transport height: 900mm ±20mm.

Transfer direction: L to R or specify R to L

Power supply: 110V /220V, 50 Hz/ 1 Ph, max 100VA

Air supply& consumption: ≥6 bar, max10 ltr/min.

Pitch distance: 10.20.30.40mm pitch or specify.

Time feed: 6 seconds Approx. Or specify.

Magazine change-over time: ±30 seconds

Conveyor Speed:0.5-20m/min adjustable

Pitch distance:10.20.30.40mm pitch or specify.

Magazine storage: 50 pcs.

Features:

- The L type magazine loader consists of two parts: the lifting mechanism and the tray waiting track, ensuring efficient PCB handling in SMT production.

- Control the magazine loader effortlessly with PLC and a user-friendly touch screen interface, allowing easy digital parameter input for seamless operation.

- The machine also prevents PCB damage with adjustable thrust settings based on PCB thickness using pneumatic or motorized pushers, ensuring tray integrity during loading.

- Benefit from the high-speed, low-noise, and durable imported ball screw for the lifting mechanism , guaranteeing precision and longevity.

- Customize tray capacities to accommodate up to 50 PCBs per tray for extended unmanned operation, optimizing efficiency and automation in PCB handling processes.

- Easily identify and address issues with the automatic fault code display feature, ensuring smooth and uninterrupted production.

- Seamlessly integrate the L type magazine loader with other equipment through the SMEMA interface for enhanced connectivity and online production capabilities.

- Experience user-friendly operation with the ‘soft touch’ LED membrane control panel of the L type PCB loading equipment, simplifying machine control and monitoring.

- Ensure PCB integrity with a specialized gas circuit design in the machine, guaranteeing no breakage during handling and transportation.

- Enhance tray alignment and stability with pneumatic clamps provided for magazine positioning, securing top and bottom sections for reliable operation.

- Maximize productivity with quick magazine change-over times and high throughput rates, optimizing production efficiency in SMT factories.

- Rely on the durable cables for long-lasting performance and robust connectivity, ensuring consistent operation over time.

- Benefit from the sturdy and stable design magazine loading machine, providing a reliable and efficient solution for PCB handling needs.