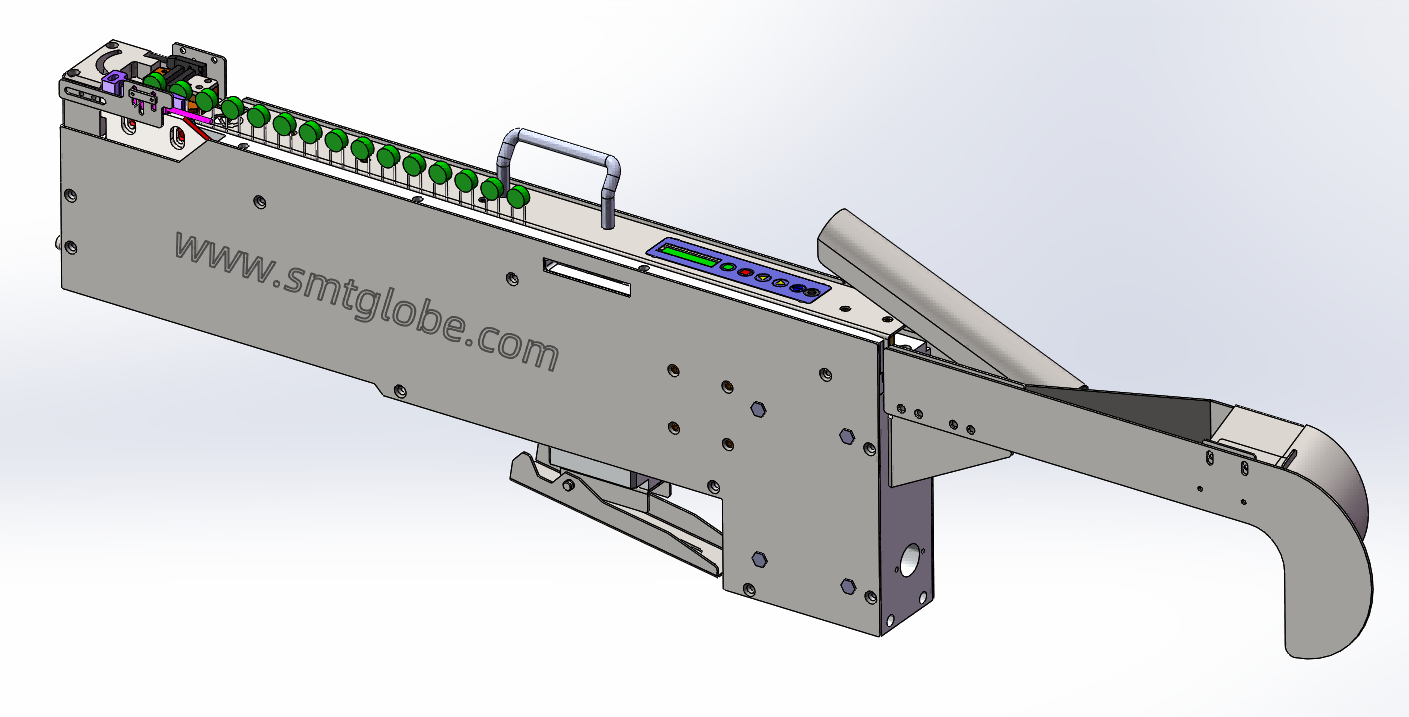

The Juki radial tape feeder is an upright, vibratory tape reel system designed to reliably feed radial electronic components for flexible SMT assembly. This feeder utilizes gear to orient chip parts and advance the tape, delivering components in sequence to the pick-up location. Perfectly used in Juki JM-20 machine.

Brief introduction of Juki Radial Tape Feeder

The Juki Radial Tape Feeder features a compact radial design with adjustable tape reels to accommodate various component sizes, effectively saving floor space. It ensures smooth tape advancement with customizable vibration amplitudes to handle delicate chips delicately. Equipped with a dual anti-static bar system, it prevents electrostatic charge buildup for added component protection. The feeder includes tape counters and sensors for precise monitoring and control, along with easy loading and changing of component tapes. Its robust construction allows for continuous 24/7 operation with minimal maintenance required. Integrated with pick-and-place machines for automated assembly, the Juki Radial Tape Feeder offers a cost-effective solution for high-mix, low-volume production. Its radial configuration, vibratory tape driving mechanism, and modular reel design make it ideal for supplying radial SMT components such as resistors, capacitors, diodes, and transistors. These feeders enable flexible and efficient component handling in electronics manufacturing processes.

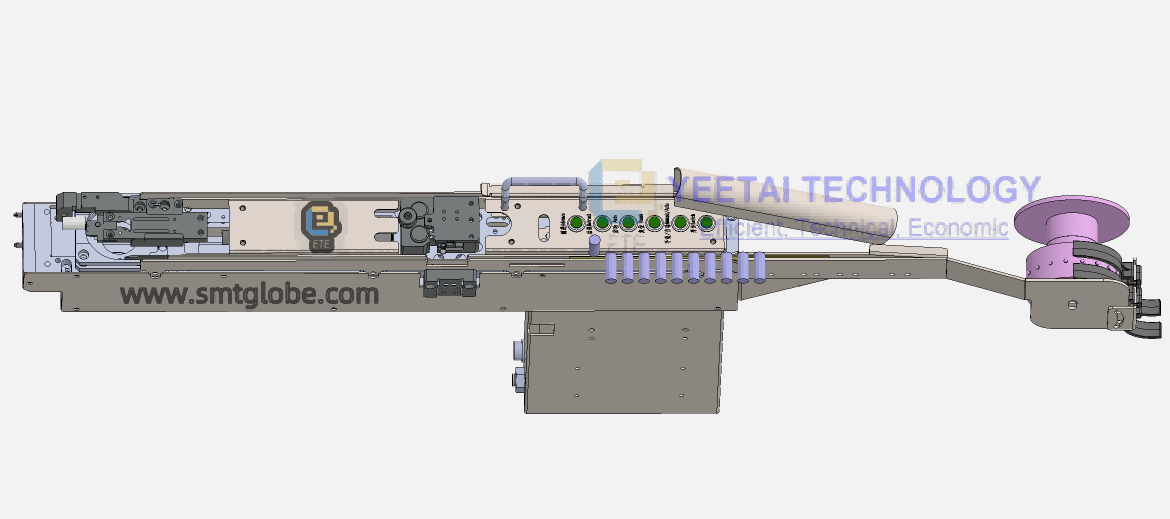

Specifications of Juki Radial Tape Feeder

| Model | Juki Radial Tape Feeder | ETE-RT03 |

| Dimension | Length x Width x Height | 720x92x165mm |

| Weight | 10Kg | |

| Applicable components | Material Type | Electrolytic Capacitor, Y Capacitor, Square Capacitor, Terminal, Spring, Bending Resistor |

| Overall Dimension | 2x2x3-15x15x30mm | |

| Wire Diameter | Core 0.3-1.0mm | |

| Cutting Length | 3-6mm (length adjustable) | |

| Tape paper hole distance | 12.7mm and 15mm (These two types are not interchangeable) | |

| Structure Part | Feeding Method | Vertical Braiding Belt Feeding |

| Feeding | Motorized feeding with two feed wheels | |

| Cutting function | Made of imported materials, adjustable length of cut foot | |

| Shaping function | Replacement of different shaping molds according to foot spacing | |

| Bending function | Possibility of 90° bending of components (this function is optional) | |

| Material Positioning | Split piece | |

| Paper belt discharge | Rotary transfer by means of feed wheels (tail can be optionally cut off) | |

| Electric part | Working Voltage | 24V |

| Average current/peak current | 4A/6A | |

| Working air pressure | 0.4-0.6Mpa |

| Operation | Push button operation |

| Machine connection | 8 pole ø16mm aviation plug |

| Communication | Support IO communication or no communication self control |

| Control mode | PLC control |

| Driving method | Stepping motor |

| Motor | Type 42/86 |

| Motor speed | 600rpm |

| Cycle time | 1S |

| Feed position adjustment | Y-direction adjusted by adjusting dividing piece, X-direction adjusting limit block position |

| Feeding accuracy | ±0.2mm |

| Feeding with or without detection | Detected by front-end fiber optic, when there is no material for 3 times in a row, it will alarm. |

| Feeding test | Achieve 1000 times of continuous feeding without any abnormality |

| Aging test | Continuous operation for 48 hours without any abnormality |

| Service life | Service life 5 years |

| Cutter life | 5 million times (cutter is consumable) |

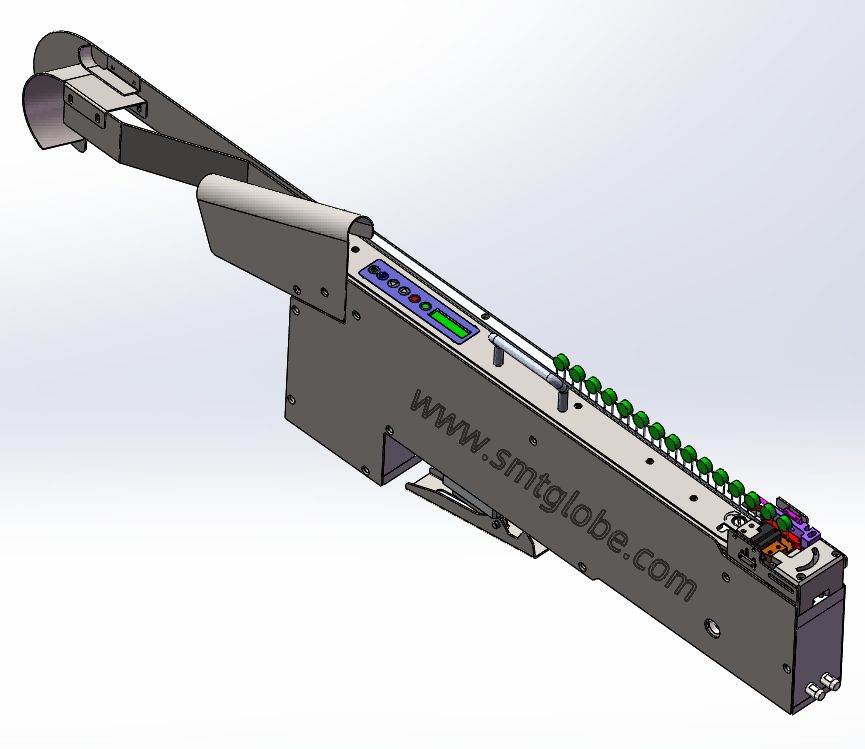

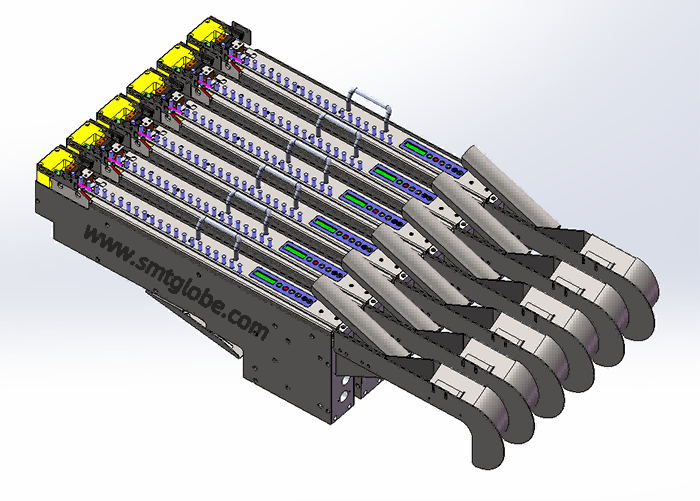

Features

- The Juki radial tape feeder automatically feeds, shapes, trims, bends, and processes electronic components on tape.

- By mounting the Juki radial tape feeder on a pick-and-place machine (or similar proprietary equipment), DIP component placement is achieved, saving on labor and reducing transfer processes.

- Installing the feeder on a custom-shaped insertion machine enables automated insertion, with the option to customize feeders for different insertion machines.

- The Juki radial tape feeder can be integrated with non-standard equipment for automated insertion, heat shrink tubing application, and component forming.

- Custom feeders for various machine types can be tailored to customer specifications, including options for tape cutting and component bending.

Special Notes Before Using Juki Radial Tape Feeder

This feeder is designed according to your requirements and the performance of the machine. It is a non-standard feeder.

Feeder power supply is DC24, and please do not make it work with too high or too low voltage, otherwise it will cause burning damage to the control board.

Air pressure should be more than 0.6Mpa. If less than this value, it will cause the material not to be delivered properly when feeding material.

Do not short-circuit the 24V with 0V of the Feeder, otherwise it will burn out all electrical components.

With SMEMA wire, feeder can communicate with the SMT/THT machine. Please connect the feeder with SMEMA wire, otherwise the machine may not be able to get the material, and an alarm occurs. SMT/THT machine must supply 0V (GND) when communicating.

The head of optical fiber in the feeder should be wiped with cleaning agent (alcohol) regularly to prevent dust from affecting the optical fiber.

Feeder must be installed firmly. Install it on the SMT/THT machine and lock the Feeder tightly.

If you need more other feeders, we can also help. Please email us or visit our website.