As intelligent design trends move towards thinner and smaller components with higher precision, the materials used in various parts are becoming increasingly delicate. To meet these demands and the ever-growing expectations of the market, it is vital to explore new applications and efficiently separate different intelligent elements from printed circuit board assemblies (PCBA). In PCB depaneling, there are stringent requirements for precision and additional functionalities, such as stress-free cutting, burr-free edges, high accuracy, and full automation.

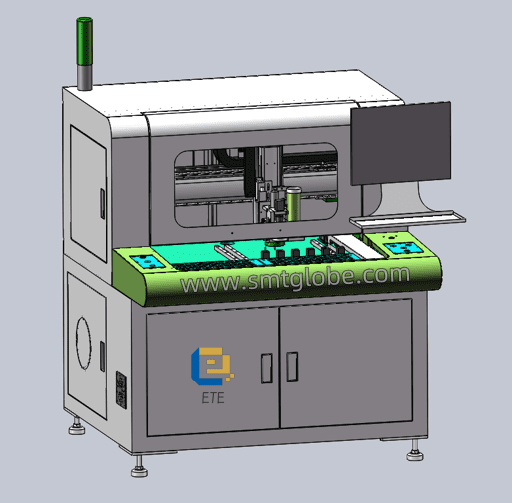

In modern SMT workshops, it is essential to use PCB depaneling machines whenever PCBA boards are involved. However, the type of PCB depaneling machine required can vary significantly based on production process requirements. Below are some common scenarios:

- V-Groove Boards: For V-groove boards where high precision is not a top priority, a knife-type PCB depaneling machine is sufficient. If the focus is on increased output, an inline knife-style PCB depaneling machine is often selected.

- Postal Hole PCBA Boards: When the requirements for the product are not very strict, offline milling machines can be used for postal hole PCBA depaneling. However, if high production volume is essential, an inline milling PCB depaneling machine, which is fully automated, is recommended to achieve an intelligent workshop without human intervention.

- Special Material Boards: For boards made of materials such as ceramic, metal, or glass, a laser cutting machine is typically chosen due to its ability to handle these specialized materials with precision and care.

In conclusion, the incorporation of PCB depaneling machines in SMT workshops is not only necessary for maintaining production efficiency but also for adhering to the evolving standards of quality and precision in the electronics industry. As designs become more intricate, investing in the appropriate depaneling technology is crucial for manufacturers aiming to stay competitive in a dynamic market.

We are experienced at PCB depaneling. Know more PCB depaneling solutions in our website: www.smtglobe.com