A soldering iron tip that won’t tin can make your work harder. This article will help you fix this problem and avoid it in the future.

Problems: How to judge if Your Tip Isn’t Tinning?

Here are some signs that show your soldering iron tip isn’t working well:

- Black Tip: The tip may become black and hard.

- Solder Won’t Melt: The solder may not melt or may form little balls that fall off.

These problems happen when junk builds up on the tip. Organic materials, like leftover rosin and plastic from wires, can stick to the tip. If not cleaned, these materials can form a hard, black layer when heated. This makes it hard for the tip to transfer heat. As a result, the solder won’t melt or stick.

2 tips you may need to know for Maintenance of Soldering Iron Tip

1. Clean the Tip

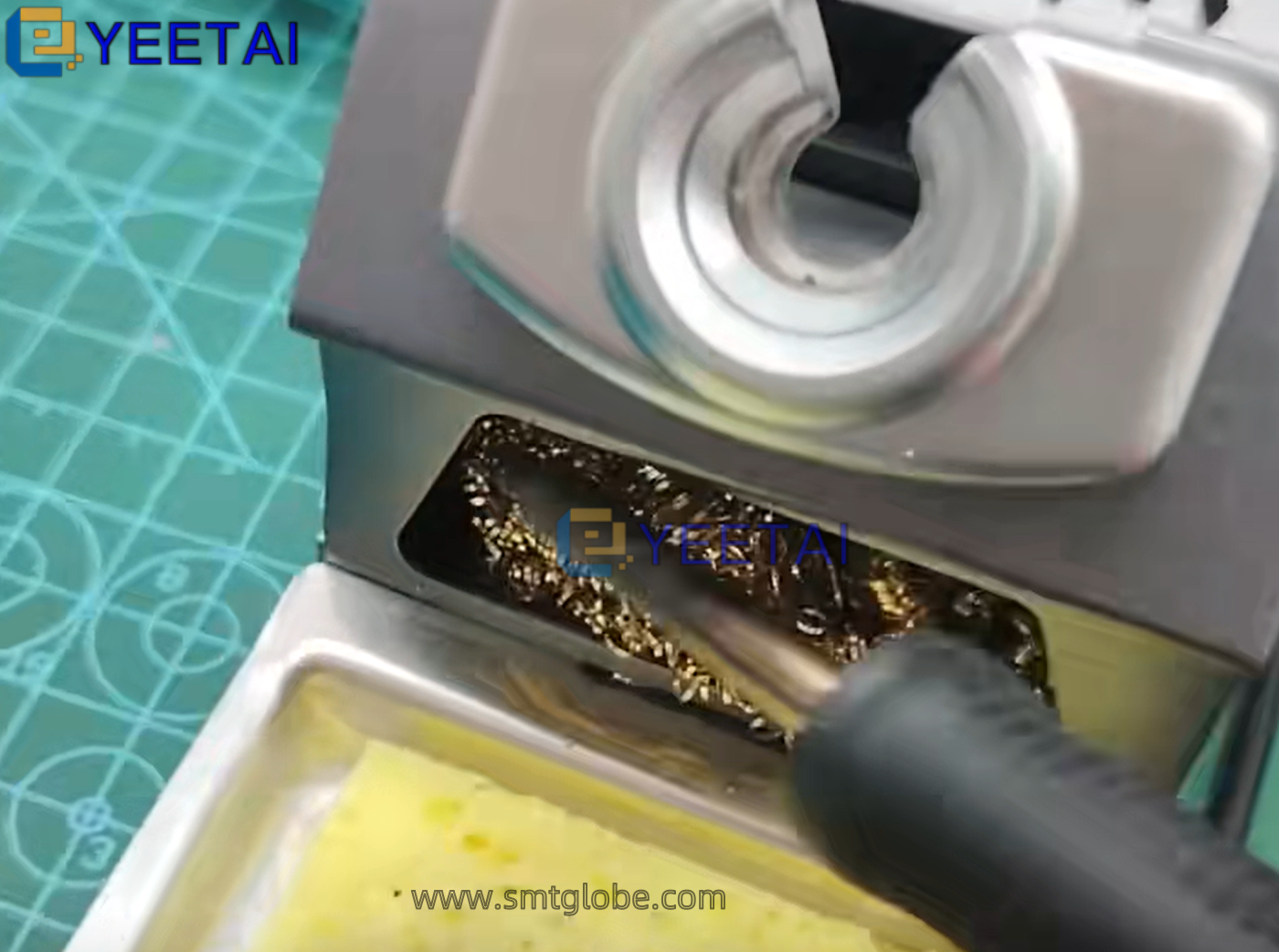

Use a Brass Wool Pad

Start by using a brass wool pad. Gently rub the tip with it. This should help remove the surface junk.

Use a Blade to Scrape

If the buildup is really bad, you can use a blade. Make sure to keep the blade vertical and apply light pressure. Be careful not to scratch the tip. Rotate the tip while you scrape to get rid of all the black stuff.

2. Re-tin the Tip

After cleaning, try to re-tin the tip. If the solder doesn’t go on smoothly, do this:

- Turn Down the Temperature: Lower the soldering iron’s heat to avoid overheating.

- Use Rosin: Get a piece of cardboard and put some rosin on it. Rub the tip on the rosin. This helps the solder stick better.

How to Prevent the Problem–Watch the Temperature and Clean and Re-tin Often

To avoid this problem in the future, keep these tips in mind:

- Watch the Temperature: Use the right heat to stop organic materials from breaking down too fast.

- Clean and Re-tin Often: Clean the tip and put solder on it after each use. This keeps it in good shape.

Conclusion

With these steps, you can fix soldering iron tips that don’t tin and keep them working well. We hope these simple tips improve your soldering experience!

If you have questions or need more tips, please leave a comment below. We’re here to help!

We are good at manufacturing soldering machine spare parts, such as selective soldering nozzles.