In the electronics manufacturing industry, the use of soldering irons is essential for assembling components onto printed circuit boards. However, one often overlooked aspect of soldering iron usage is the potential for electrostatic discharge (ESD) to damage sensitive electronic components. To prevent ESD incidents and ensure the integrity of electronic devices, it is crucial to implement proper anti-static measures when using soldering iron tips. That’s why we will share this article.

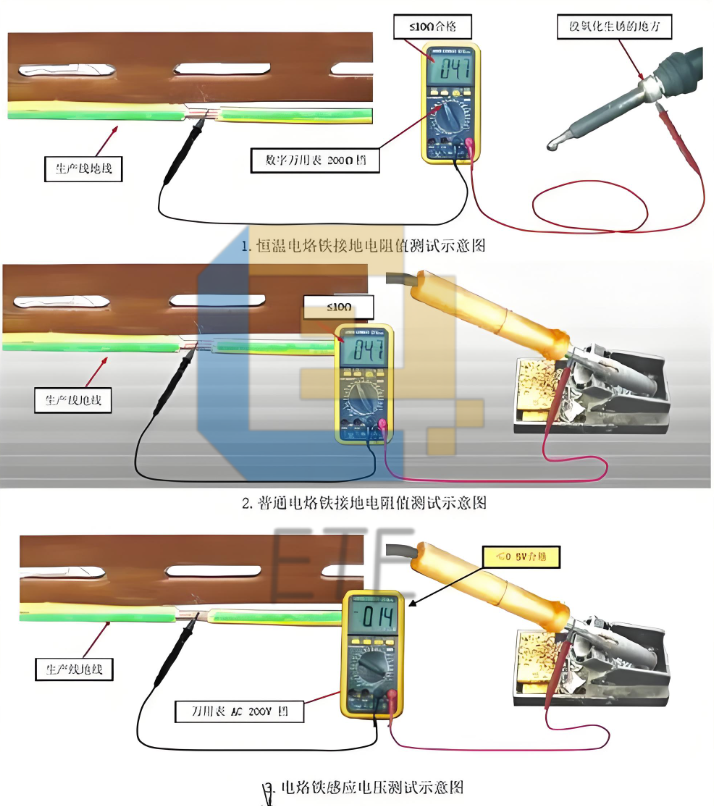

- Grounding the Soldering Iron: One of the most effective ways to prevent ESD is to ensure that the soldering iron is properly grounded. By connecting the soldering iron to a grounded outlet or mat, any static electricity buildup can be safely dissipated, reducing the risk of ESD-related damage.

- Using ESD-Safe Equipment: When working with sensitive electronic components, it is important to use ESD-safe soldering equipment. This includes ESD-safe soldering irons, tips, and workstations that are designed to the prevention of electrostatic discharge. These specialized tools are designed to minimize the risk of ESD incidents during soldering operations.

- Proper Handling and Storage: Soldering iron tips should be handled with care to prevent damage or contamination. When not in use, soldering iron tips should be stored in a clean and dry environment to avoid exposure to moisture or dust, which can increase the risk of ESD. Additionally, using tip cleaning tools and maintaining the soldering iron tip cleanliness can help ensure optimal performance and reduce the likelihood of ESD events.

- ESD Training and Awareness: Educating personnel on the importance of ESD prevention and proper soldering iron tip handling is essential in maintaining a safe working environment. Training programs should cover ESD risks, handling procedures, and best practices to mitigate the potential impact of static electricity on electronic components.

By implementing these anti-static measures when using soldering iron tips, electronic manufacturers can protect sensitive components from ESD damage and ensure the reliability and quality of their products. Prioritizing ESD prevention in soldering operations is key to maintaining a safe and efficient production process in the electronics industry.

In conclusion, safeguarding against electrostatic discharge with proper handling, grounding, and storage tools is crucial for protecting electronic components during soldering operations. By following these anti-static measures, manufacturers can minimize the risk of ESD-related damage and uphold the integrity of their electronic devices.