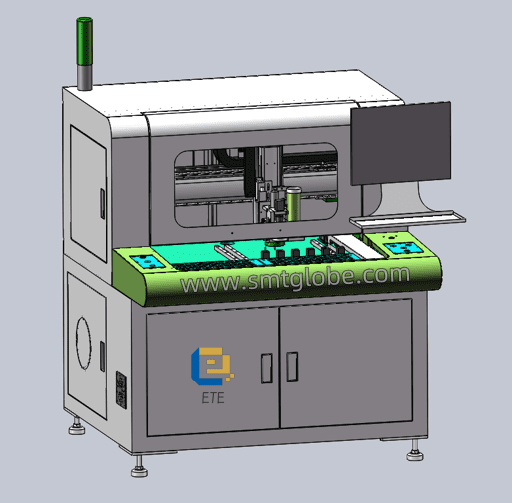

Guillotine PCB depaneling machines are widely used in the electronics industry for cutting PCBs into individual units. However, like any piece of machinery, they can encounter various issues that might interrupt their operation. Below are five common problems associated with guillotine PCB depaneling machines and their respective solutions.

1. Indicator Light Does Not Illuminate After Powering On

Possible Causes:

- Blown Fuse: One potential reason for the indicator light not functioning is a blown fuse.

- Emergency Stop Button: Another possibility is that the emergency stop switch has not been disengaged.

Solution:

- Check the fuse and replace it if it is blown.

- Ensure that the emergency stop button is properly released.

2. Inaccurate Stroke Measurement

Possible Causes:

- Faulty Stroke Counter: The stroke counter may be malfunctioning or broken.

- Dust Accumulation: Excessive dust buildup on the counter can lead to inaccuracies.

Solution:

- If the count is faulty, it may be necessary to replace the stroke counter.

- If dust is the issue, cleaning the counter should resolve the problem.

3. Blade Hits the Left Side Panel

Possible Causes:

- Faulty Left Stroke Sensor: The left stroke optical sensor may not be functioning correctly.

- Dirty Sensor: Accumulated dust can interfere with the sensor’s operation.

Solution:

- Replace the left stroke optical sensor if it is defective.

- Clean the sensor to remove any dust that may be obstructing its functionality.

4. Blade Hits the Right Side Panel

Possible Causes:

- Faulty Right Stroke Sensor: Similar to the left side, the right stroke optical sensor may be malfunctioning.

- Dirty Sensor: Dust accumulation can also affect the right stroke sensor.

Solution:

- Replace the right stroke optical sensor if necessary.

- Clean the sensor to ensure proper operation.

5. Motor Turns but Blade Does Not Rotate

Possible Causes:

- Loose Coupling Set Screw: A potential cause for this issue could be a loose set screw on the coupling.

Solution:

- Open the rear cover of the machine and tighten the set screw to ensure that the motor is properly connected to the blade mechanism.

Conclusion

By addressing these common issues with guillotine PCB depaneling machines, operators can maintain optimal performance and reduce downtime. Regular maintenance and quick troubleshooting can help ensure smooth operation, enhancing productivity and efficiency in PCB manufacturing processes. Should problems persist despite these solutions, it is advisable to consult the manufacturer’s manual or contact technical support for further assistance.

We are experienced at PCB depaneling. Know more PCB depaneling solutions in our website: www.smtglobe.com