Full Conformal Coating Machine:offers consistent quality of full coating PCB surfaces

The PCB coating process currently faces several challenges that can impact product quality and operational efficiency:

- Inconsistent Coating Volume and Thickness: Inaccurate control of coating time or unstable factory air supply leads to significant variability in coating volume and thickness.

- Environmental Pollution: Open operations result in substantial waste gas emissions, contributing to pollution.

- Temperature Control: Difficulty in selecting the optimal baking temperature corresponding to coating thickness exacerbates quality issues.

- Pre-Masking Needs: The necessity for fixtures to mask areas prior to coating adds to the complexity.

- Inconsistent Adhesive Application: Poor control of adhesive volume at the start and end points of the coating process can lead to defects.

- Width Control Challenges: Achieving consistent coating width across different products can be difficult.

- Low Efficiency: Overall coating efficiency is low, resulting in higher labor costs.

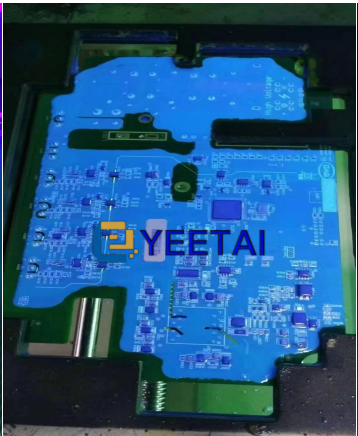

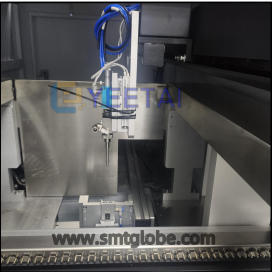

Our Full Conformal Coating Machine is the ideal solution for achieving the full coating of PCB surfaces. Designed for mass production, this inline machine addresses the following issues:

Key Benefits of the Full Conformal Coating Machine

- Mitigating Air Supply Fluctuations: Our machine effectively mitigates the impact of fluctuations in factory air supply on adhesive application.

- Consistent Adhesive Volume and Thickness: By resolving issues of inconsistent adhesive application, our machine ensures the uniform quality of each PCB coating.

- Reliable Coating Performance: It guarantees uniform reliability of the coating after application on circuit boards, enhancing product longevity and performance.

- Temperature Variability Management: The machine’s design addresses the effects of environmental temperature changes on the adhesive, ensuring optimal coating performance.

- Versatile Coating Valves: Equipped with various types of coating valves, the machine effectively meets diverse coating process requirements for different products while preventing adhesive leakage.

- Closed System Reduces Pollution: Our machine features a closed coating system that generally minimizes air pollution in the workshop.

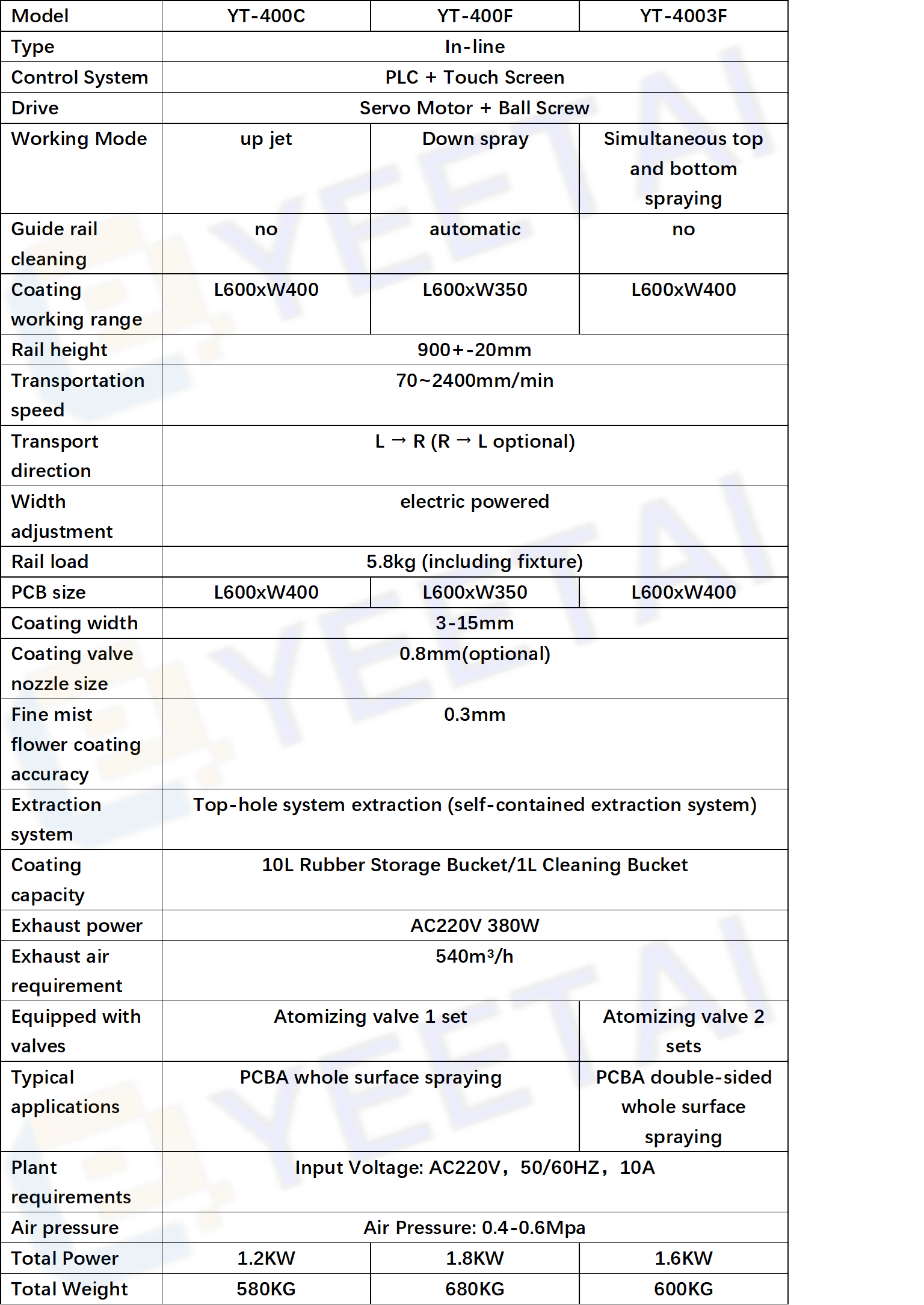

Specification

Features of the Full Conformal Coating Machine

- Sturdy Construction: A robust steel motion platform and solid frame structure ensure stable operations.

- High-Precision Sealed Modules: Complete isolation of mist from corroding critical components, offering superior stability and precision over traditional systems.

- Durable Materials: Specialized aluminum alloy tracks and stainless steel conveyor chains increase the durability and longevity of the equipment.

- User-Friendly Interface: An intuitive interface with quick programming capabilities significantly reduces setup and programming time.

- Speed and Stability: Fast operation speed while maintaining high stability, enhancing overall production efficiency.

- Advanced Process Control: Ensures high quality and consistency in coating, critical for meeting industry standards.

- Effective Waste Disposal: An independent coating container with a waste gas discharge outlet effectively reduces the emission of harmful gases.

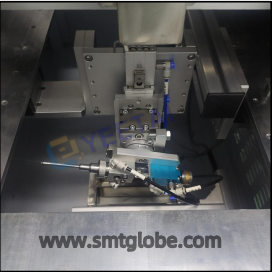

- Adjustable Spray Technology: The German-engineered spray valve allows for precise adjustments in atomization fan size and width.

- Automatic Features: Automatic soaking and dispensing devices prevent the clogging of the adhesive outlet.

- Integration Capabilities: Features SMEMA interface for seamless communication with other machines and equipment.

- Safety and Convenience: Equipped with sound and light alarms for faults, menu displays, and a lighting system, including a UV detection light source for easy operational monitoring.

Advanced Machine Configuration

Machine Configuration

- Durability: Integrated sheet metal construction for robustness.

- High-Performance Drive: Internal Japanese imported servo motors combined with ball screw drive for accurate movement.

- Customizable Coating Options: Capable of choosing top and bottom spraying configurations based on specific product requirements.

Control Systems: PLC + touchscreen for enhanced operational control.

- Negative Pressure Exhaust System: Built-in system reduces unpleasant odors from workshop waste gases.

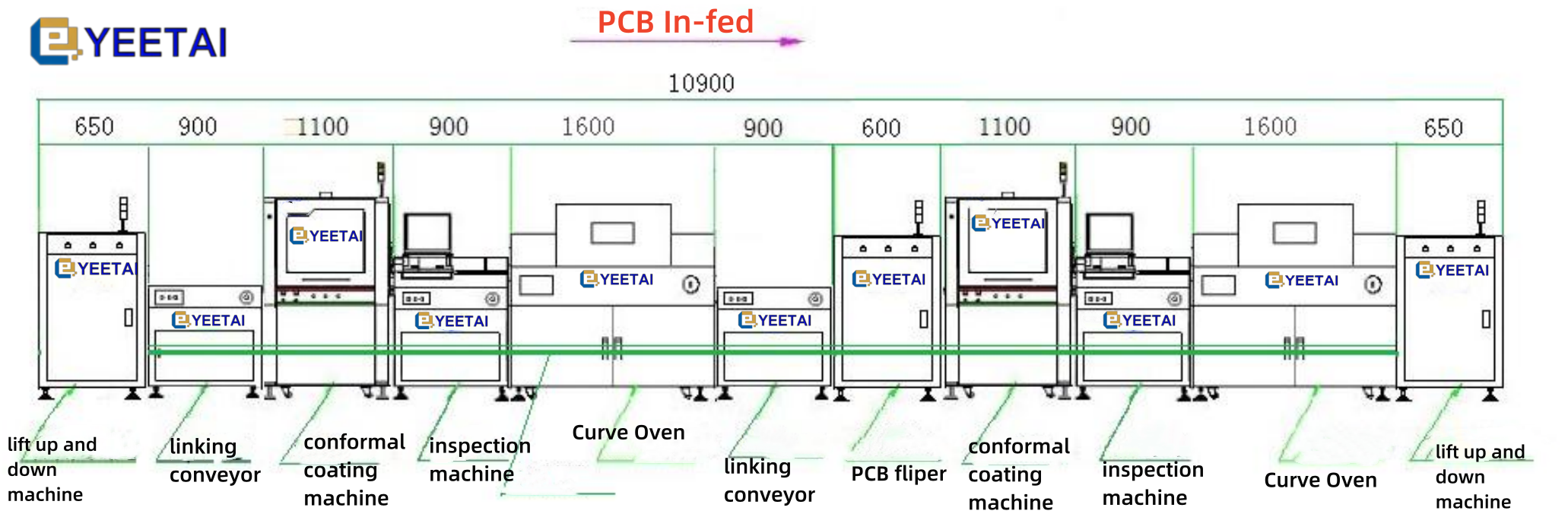

Conformal coating full line solution

We offer full line solutions of conformal coating process. You may read below pages.

Selective Conformal Coating Machine

Full conformal coating machine