Looking for a Reliable ESD PCB Trolley? Contact Us!

Our ESD trolley has precise slots and allows smooth placement for PCB boards. It has a stable electrostatic discharge (ESD) index. This design helps protect your electronic products effectively.

ESD PCB Trolley Features

- Strong Material: Our trolley uses industrial-grade SUS304 steel. This material resists corrosion and lasts a long time.

- Stable ESD Performance: We carefully control quality to ensure a stable ESD index. This feature keeps your working environment safe for electronics.

- Metal Grounding Chain: The trolley comes with a metal chain that discharges static electricity. This helps protect your electronic components.

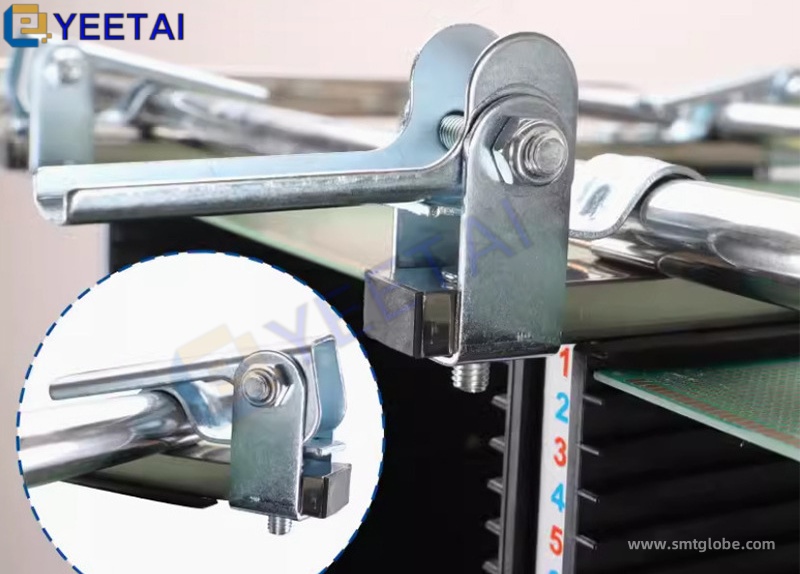

- Adjustable Design: The movable pressure buckle lets you adjust it easily for different PCB sizes. This feature keeps the boards stable.

- Silent Universal Wheels: The universal wheels are designed to move quietly. This way, you can move the trolley without making noise.

Specification

Model: ET460L

External dimensions: (L) 900 * (W) 600 * (H) 1280MM

Surface resistivity: 10 ^ 4~10 ^ 6 Ω 10 ^ 6-10 ^ 9 Ω

System resistance: ≤ 107 Ω

The length of the slot plate includes: 350MM, 460MM, 530MM, 630MM

Dimensions related to groove plates: groove depth of 4mm, groove width of 5mm, groove spacing of 10mm

PCB storage standard: Each column stores 100 pieces and can be equipped with 2 columns/3 columns/4 columns/5 columns/6 columns. The storage capacity of the entire vehicle can be determined according to customer needs.

Configuration: Two universal wheels, two brake wheels, galvanized fixed wrench, two single-sided side panels, and two double-sided side panels

Material: The car body is made of stainless steel, and the side panels are made of anti-static plastic (permanently anti-static)

Easy Installation Steps of ESD PCB Trolley

- Open the first single-sided panel.

- Install the wheels on the two frames.

- Tighten the screws for the four crossbars.

- Securely install the four crossbars.

- Place the first single-sided panel on the crossbars.

- Install the second single-sided panel.

- Tighten the screws on the second frame.

- Stand the trolley upright, and ensure all screws are tight.

Why Choose Our ESD Trolley?

We focus on precision and quality. Thus, we provide you with a high-quality experience. Safety and stability in the electronics industry are crucial. Therefore, choose our ESD PCB trolley to keep your electronic products safe and worry-free.

Contact Us

If you want more information or need a quote, please contact us. We are eager to provide you with quality products and great service.