ESD PCB Storage Trolley – The Ultimate Anti-Static Solution for Efficient and Organized Management of Printed Circuit Boards in Electronic Manufacturing Industries. In order to provide an anti-static environment for the transportation and storage of PCBs, we design and produce it.

Description

The ESD PCB Storage Trolley consists of anti-static side panels and stainless steel pillars, equipped with 4 casters.

Acid and alkali resistant, oil-resistant, non-toxic, and odorless. It is suitable for storing PCB boards.

Easy to clean, it allows for convenient PCB board turnover.

With rational design and excellent quality.

Thus, the ESD PCB Storage Trolley is suitable for transportation, distribution, storage, and processing in the logistics of SMT factories.

In addition, you can use our ESD PCB Storage Trolley in various warehouses, production sites, and other settings. With the increasing emphasis on warehouse logistics management by many SMT factories today. It is also an essential tool to boost management in the electronics manufacturing industry.

Specification

Model: ET350L

External dimensions: (L) 850 * (W) 550 * (H) 1300MM

Surface resistivity: 10 ^ 4~10 ^ 6 Ω 10 ^ 6-10 ^ 9 Ω

System resistance: ≤ 107 Ω

The length of the slot plate includes: 350MM, 460MM, 530MM, 630MM

Dimensions related to groove plates: groove depth of 4mm, groove width of 5mm, groove spacing of 10mm

PCB storage standard: Each column stores 100 pieces. 2 columns/3 columns/4 columns/5 columns/6 columns available.

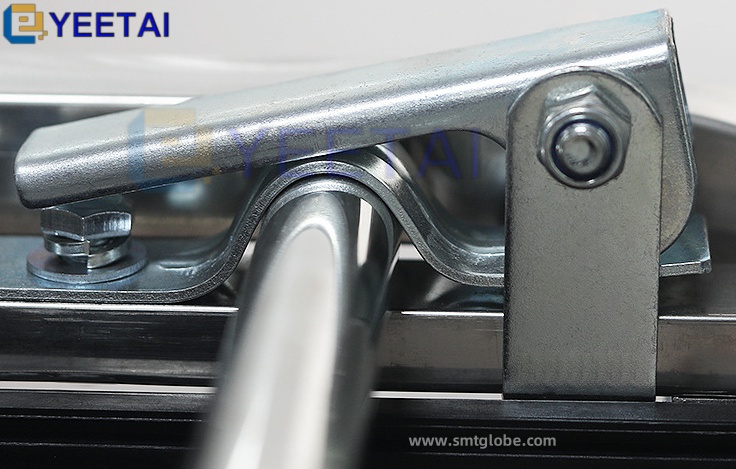

Configuration: Two universal wheels, two brake wheels, galvanized fixed wrench, two single-sided side panels, and two double-sided side panels

Material: The car body of stainless steel, and the side panels of anti-static plastic (permanently anti-static)

| Overall Size (L*W*H) mm | Slot Length (mm) | PCB Storage Qty |

| 900*550*1300 | 350mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*600*1280 | 460mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*650*1280 | 530mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*700*1280 | 630mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs |

Features

The ESD PCB Storage Trolley comes with 2 directional brake wheels and 2 universal wheels. The threaded brake wheels can rotate 360°. Suitable for various terrains, and even on slopes. The brake device ensures secure parking without slippage. The universal wheels move freely, allowing easy navigation in every corner of SMT production workshops. Being lightweight and durable.

Each anti-static board with 4 snap fasteners to secure it in place. It uses metal snap fasteners to easily fix the distance between each column. The slot spacing is freely adjustable to meet different requirements.

It comes with a digital scale, precise slots where each scale represents a slot.Ensuring accurate and smooth board placement for easy management.

With a metal chain for grounding. Effectively releasing static electricity to provide excellent protection for PCBs.

With a large storage capacity, one rack can store 100-500 PCBs. You can adjust each column according to the size of the PCBs. Effectively utilizing factory space and reducing costs.

Installation Process of ESD PCB Storage Trolley

- First, place one of the rods on the frame and secure it with bolts, then gradually secure the other four rods using the same method.

- Place the unidirectional plastic board at the bottom, followed by the bidirectional boards (the quantity of bidirectional boards is determined by customer requirements), and then the unidirectional board.

- Place the frame on top of the rods and secure it with bolts.

- Install the wheels by individually screwing them in by hand, and finally, position the bidirectional and unidirectional boards accordingly.

You can buy an ESD trolley from us directly. You can also visit our website to learn how to quickly install an ESD PCB storage trolley.