You may encountered Common Problems with ESD PCB Storage Cart as follows

Many Brands, Little Assurance

When buying ESD PCB storage carts, you may face issues with too many brands. Each brand offers different quality and service. This can leave you feeling uncertain about your choice.

High Prices, Average Quality

You might spend more money on a cart but find that the quality is just average. Many users discover that the carts do not meet their expectations. Thus, it is important to choose wisely.

Difficult Adjustments Hurt Efficiency

Some carts are hard to adjust. This can slow down your work. Easy adjustments can save time and improve productivity.

Weak Solder Joints Cause Problems

If solder joints are weak, they may break easily. Carts using spot welding can have this issue. Therefore, durable solder joints are essential for a long-lasting product.

We can help you solve these issues.

Why Choose Our ESD PCB Storage Cart

Focus on Quality and Customer Experience

We prioritize product quality and customer satisfaction. Our ESD PCB storage cart are reliable and easy to use. This ensures you get the best value for your money.

Stable Electrostatic Index

Our storage cart has a stable electrostatic index. The side panel test shows an index between 10^6 to 10^9 Ω. This makes our carts safe for handling sensitive electronic components.

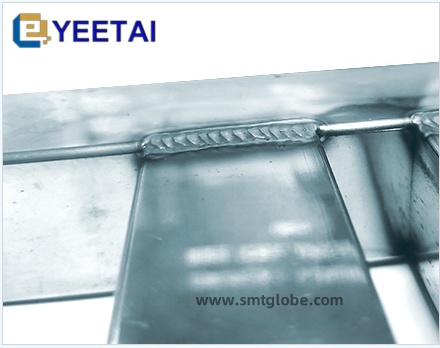

Durable Solder Joints

We use solder joints for better strength. These joints are more durable than standard spot welding. Thus, our carts are built to last.

Clear and Easy-to-Read Label Strips

Our label strips are designed for easy identification. They are clearer than silk-screen printed labels. This feature helps improve work efficiency.

Strong Steel Construction

Our carts are made with 1mm thick steel. This ensures strong and durable frames. We do not use cheap materials, as we aim to provide quality products.

Customization Available

In addition to standard sizes, we offer custom cart options. You can choose the specifications that best fit your needs.

Secure Product Packaging

We package our products securely. This protects the cart during shipping and ensures it arrives in perfect condition.

Our Production Process of ESD PCB Storage Cart

Automated Side Panel Production

We have an advanced injection molding department. We use high-quality PP material for better side panel performance. Our fully automated process ensures precision and efficiency.

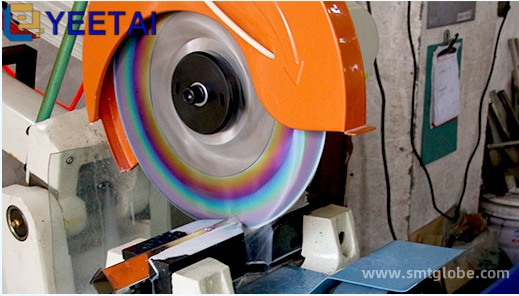

Accurate Steel Cutting

Our hydraulic cutting machines ensure precise cuts. This means we maintain tight tolerances with minimal errors.

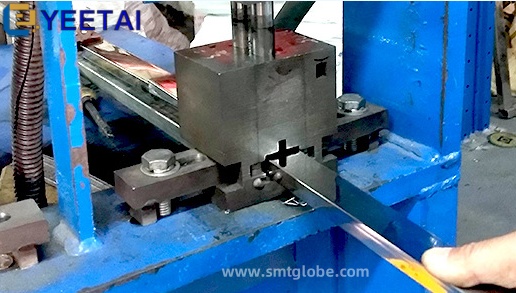

Standardized Hole Punching

We follow strict standards for punching holes. This helps the panels fit perfectly with the snap fasteners. Thus, our assembly process is smooth.

Efficient Panel Assembly

We assemble the side panels into a 100-layer cart, available in single or double panels. Our process ensures that each cart is built to last.

Professional Bending Techniques

We use specialized bending equipment for accurate frame bending. This keeps both ends of the frame at a consistent length.

Simple Installation Instructions

Stack the panels in order.

Insert the four load-bearing beams into the panel holes.

Attach the outer frame to the beams and tighten the screws.

Install one side of the wheels.

Flip the cart over and add the other frame and wheels.

Check all screws to ensure they are tight.

Conclusion

Choosing the right ESD PCB storage cart is crucial for your work. Look for high quality, durability, and ease of use. With our products, you get a reliable solution for your storage needs.

If you have any questions or need assistance, feel free to contact us!

Specification

| Overall Size (L*W*H) mm | Slot Length (mm) | PCB Storage Qty |

| 900*550*1300 | 350mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*600*1280 | 460mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*650*1280 | 530mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs | ||

| 900*700*1280 | 630mm | 200pcs |

| 300pcs | ||

| 400pcs | ||

| 500pcs | ||

| 600pcs |