Optimize Your Production Line with our Dual Lane Magazine Unloader

We’re YEETAI based in China. We can help to streamline your production line with our board handling system. Our Dual Lane Magazine Unloader ensures efficient and reliable operation for your PCB assembly line. It comes with a robust and stable sheet metal mainframe design. Its innovative cylinder pusher design effectively prevents damage to PCB boards during the unloading process. Thus, it maximizes production capacity while maintaining quality.

Key Features of the Dual Lane Magazine Unloader:

- Sturdy Structure: The unloader features a durable sheet metal construction combined with an aluminum frame for both entry and exit, all coated in a clean white finish for enhanced aesthetics.

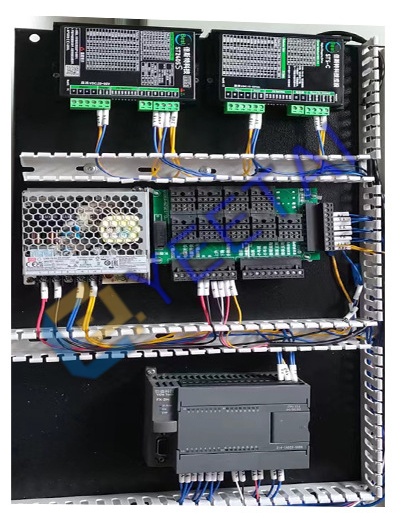

- Advanced Control System: Equipped with a reliable microcomputer PLC control system, the unloader ensures stability and precision in operations.

- User-Friendly Touch Screen Display: The touch screen interface facilitates easy operation. It features automatic fault diagnosis and seamless human-machine interaction for efficient troubleshooting.

- Sound and Light Alarms: Integrated sound and light alarms provide immediate notifications along with prompts on the touch screen. Quick response to any issues.

- Adjustable Shelf Height: You can adjust the lifting step distance according to the height of components on the PCB. Versatility in handling various designs.

- Automatic Counting Function: Ours gives you convenient production statistics, enabling better tracking of output.

- Special Air Circuit Design: Our unloader incorporates a special air circuit that protects PCB boards from damage. This significantly enhances production efficiency.

- SMEMA Compatibility: The machine is compatible with the standard SMEMA interface, ensuring seamless integration into existing production lines and equipment.

- Reliable Stepping Motor for PCB Transfer: Utilizing a stepping motor for the pushing mechanism, the unloader guarantees consistent and precise board handling.

- Customizable Motor Parameters: Operators can easily adjust the stepping motor’s pushing speed, distance, and force, enabling tailored operations to meet specific production needs.

- Adjustable Conveyor Belt Speed: You can modify the conveyor belt speed to suit various production requirements. Get optimal performance for you.

Specification

| model | EDLU258 | EDLU338 | EDLU398 |

| Applicable material frame size | 355*320*563mm | 460*400*563mm | 535*460*570mm |

| PCB board size | 50*50-350*250mm | 50*50-460*330mm | 50*50-535*390mm |

| Machine size | 1550*730*1250mm | 1800*810*1250mm | 2000*880*1250mm |

| Machine weight | 200KG | 230KG | 240KG |

| power supply | Single phase AC220V 50Hz, 60Hz | ||

| power | 150W | ||

| Lifting step distance | 10, 20, 30, 40, 50, the step distance can be set arbitrarily | ||

| Compressed air source | 5-6kg | ||

| PCB board thickness | 0.5-3.0mm | ||

| fixed edge | Front fixation (optional rear fixation) | ||

| Transmission height | 900±20mm | ||

| Transmission direction | Left to right (optional right to left) | ||

| Withstand voltage | AC terminal to ground 1500V for 1 minute | ||

| Usage environment | No corrosive gas and dust environment | ||

| Anti-interference | Voltage noise: 1000Vp-p, wave width 1us, time 1 minute | ||

Conclusion

Our Dual Lane Magazine Unloader stands out with its robust design, advanced features, and efficient operation. The incorporation of a programmable controller system, touch-sensitive control panel, and high-quality components ensure stability and superior performance, making it an essential addition to any PCB assembly line. Enhance your production efficiency and reliability with this state-of-the-art unloader.

If you need other PCB board handling equipment, we can also help. Find them as below.