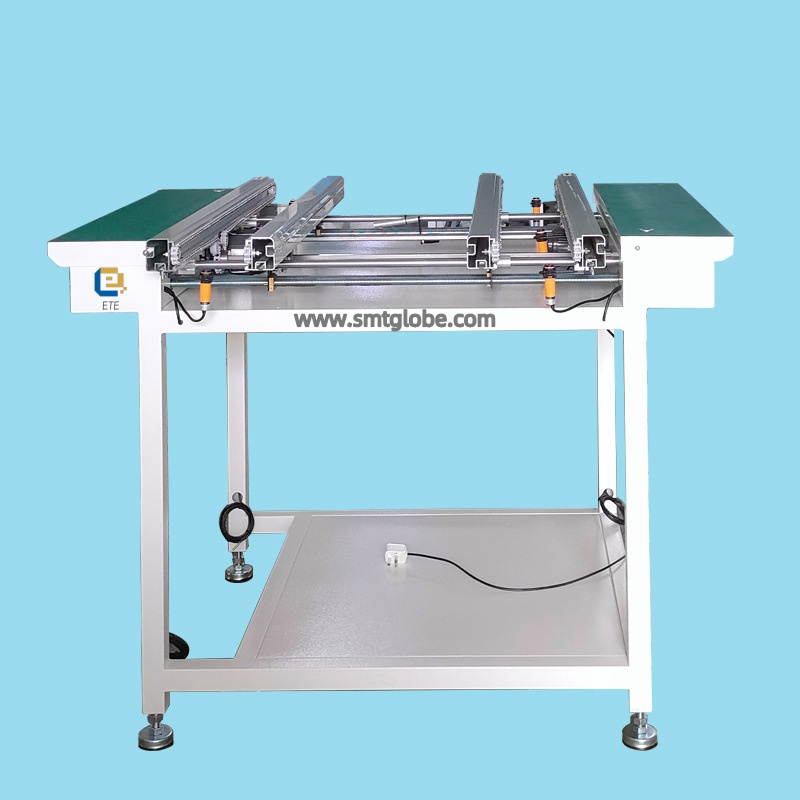

When it comes to saving reflow oven and optimizing your SMT line, the dual lane linking conveyor plays a key role. We are based in China. And we can offer high-quality SMT Peripheral equipment, including dual lane linking conveyor.

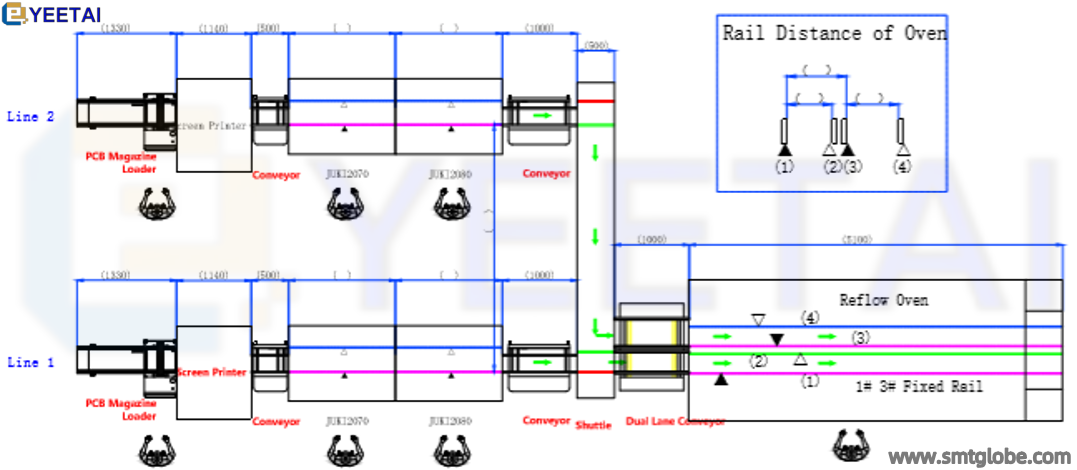

The conveyor optimizes the linking between Surface Mount Device (SMD) machines or board handling units in Dual-lane PCB assembly lines. This innovative 2-lane PCB conveyor requires ample space on the frame to seamlessly connect the two conveyor belts. With this conveyor, 1 reflow oven can be shared by 2 different SMT lines. Thus this will help you save the cost of 1 reflow oven. It provides unparalleled flexibility for varied usage scenarios.

Key Features of the Dual Lane linking conveyor

Precision Screw Adjustment: Our conveyor features precision screw adjustments. It ensures the alignment of transportation rails for enhanced stability and performance of the Dual Lane linking conveyor.

Specialized Materials: Constructed with wear-resistant and antistatic flat belts, as well as thickened aluminum profile rails. This conveyor guarantees smooth and stable transportation. This is essential for maintaining production efficiency.

Signal Line Integration: The Dual Lane linking conveyor comes with standardized signal lines. It is for seamless online connectivity with other equipment. And this facilitates streamlined operations.

Customizable Rail Lengths: We offer customizable rail lengths for the linking platform. It is tailored to meet unique customer requirements. Therefore, it makes this conveyor adaptable for various applications.

Antistatic Features: Enhanced with antistatic rubber components. Our conveyor significantly reduces static buildup. Besides, it ensures the safety and reliability of electronic components during transportation.

Advanced Motor Technology: Equipped with adjustable 4248 extended step motors. The transmission motor of the dual lane linking conveyor provides precise and efficient transport control.

Reliable Sensor Operation: With long-lasting circular photoelectric switches. And it ensures dependable performance and accuracy throughout production processes.

Stable Transmission Design: It has a double-bearing drive system for flat belt transmission wheels. This promotes stability and protects the integrity of the conveyor belt during operation.

Innovative Rail Design: The linking platform’s rails are uniquely designed to transition into octagonal shapes. Facilitating smooth and jitter-free entry and exit of PCBs. Optimizing workflow.

Screw Rod Adjustment: Dual sets of screw rods enable width adjustments. Ensure compatibility with various PCB sizes and improve operational efficiency.

Independent Rail Control: Enjoy the convenience of independent control for the dual rails. Allowing for easy operation and management of the conveyor system.

Optional Features for Enhanced Functionality

- Cooling Fans: Optional cooling fans can be installed on the top or bottom of the conveyor. Regulate temperatures post-reflow, ensuring component integrity.

- Inspection Light System: An integrated light system improves inspection capabilities. For thorough quality checks in Inspection Mode.

- Motorized Width Adjustment: For added convenience, a motorized or automatic width adjustment feature is available. Easier to accommodate various PCBs.

- Custom Transport Solutions: Choose from different belt widths or a chain transport system to align with specific operational needs.

- Foot Pedal Control: Enhance user experience with foot pedal pass control, allowing for hands-free operation.

- Storage Options: A bottom cabinet can be included for additional storage space. Aiding in organization and efficiency on the production floor.

Specification

| Model | Dimension (L*W*H.MM) | PCB size(MM) | Weight(KG) | Remark |

| EDC-500 | 500*1046*900 | 50*50-330*250 | 80KG | no Lighting |

| EDC-520 | 520*1046*900 | 50*50-330*250 | 90KG | with Lighting |

| EDC-1000 | 1000*1046*900 | 50*50-330*250 | 95KG | no Lighting |

The Dual Lane Linking Conveyoris a pivotal component for streamlining operations in PCB assembly lines, enhancing production efficiency and ensuring the durability of electronic components. Invest in our advanced conveyor system to transform your production capabilities today!

If you need other PCB board handling equipment, we can also help. See them as below.