Axial Tape Feeder ETE-AT01: A Comprehensive Solution for Automated SMT Component Feeding

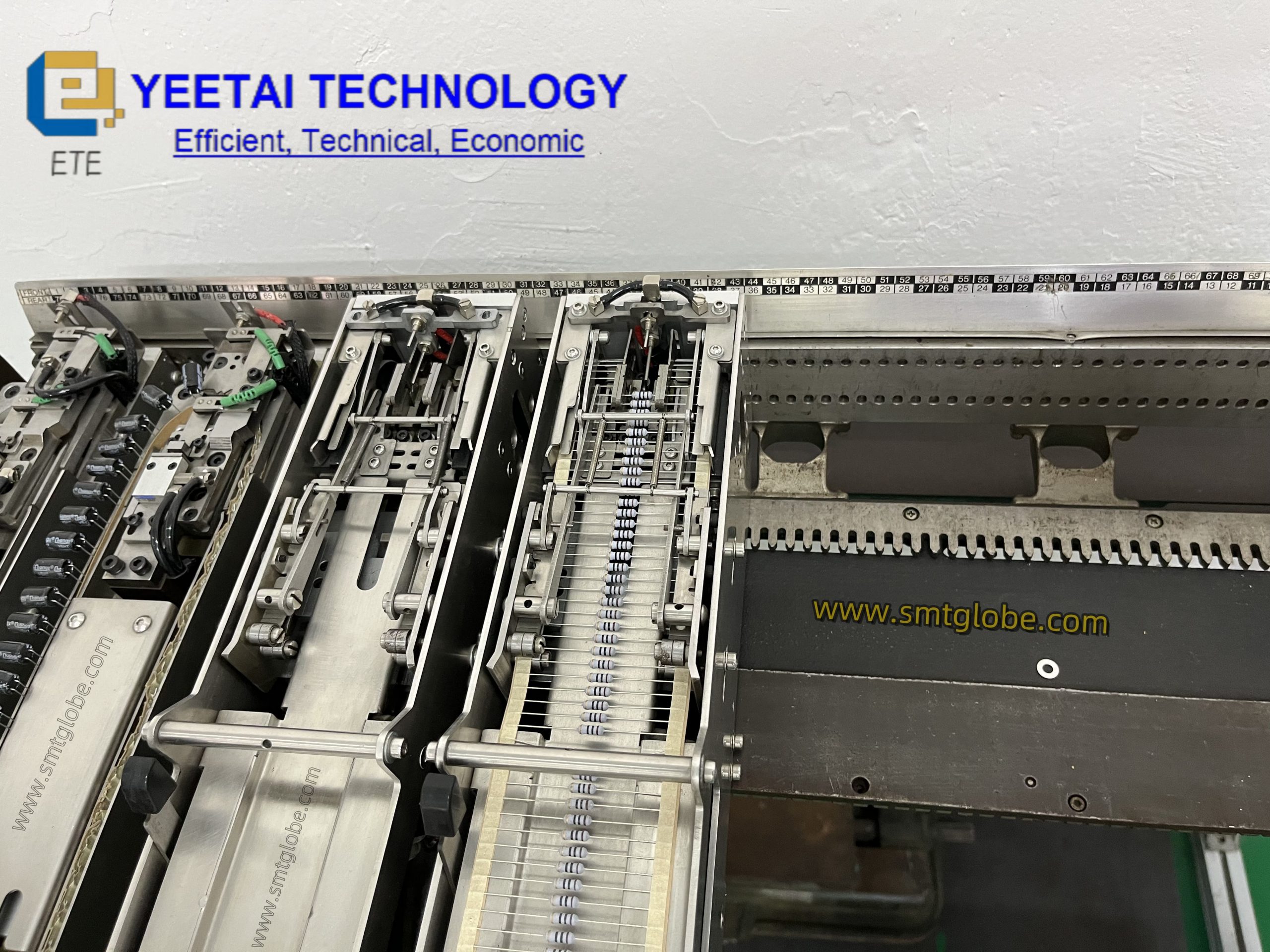

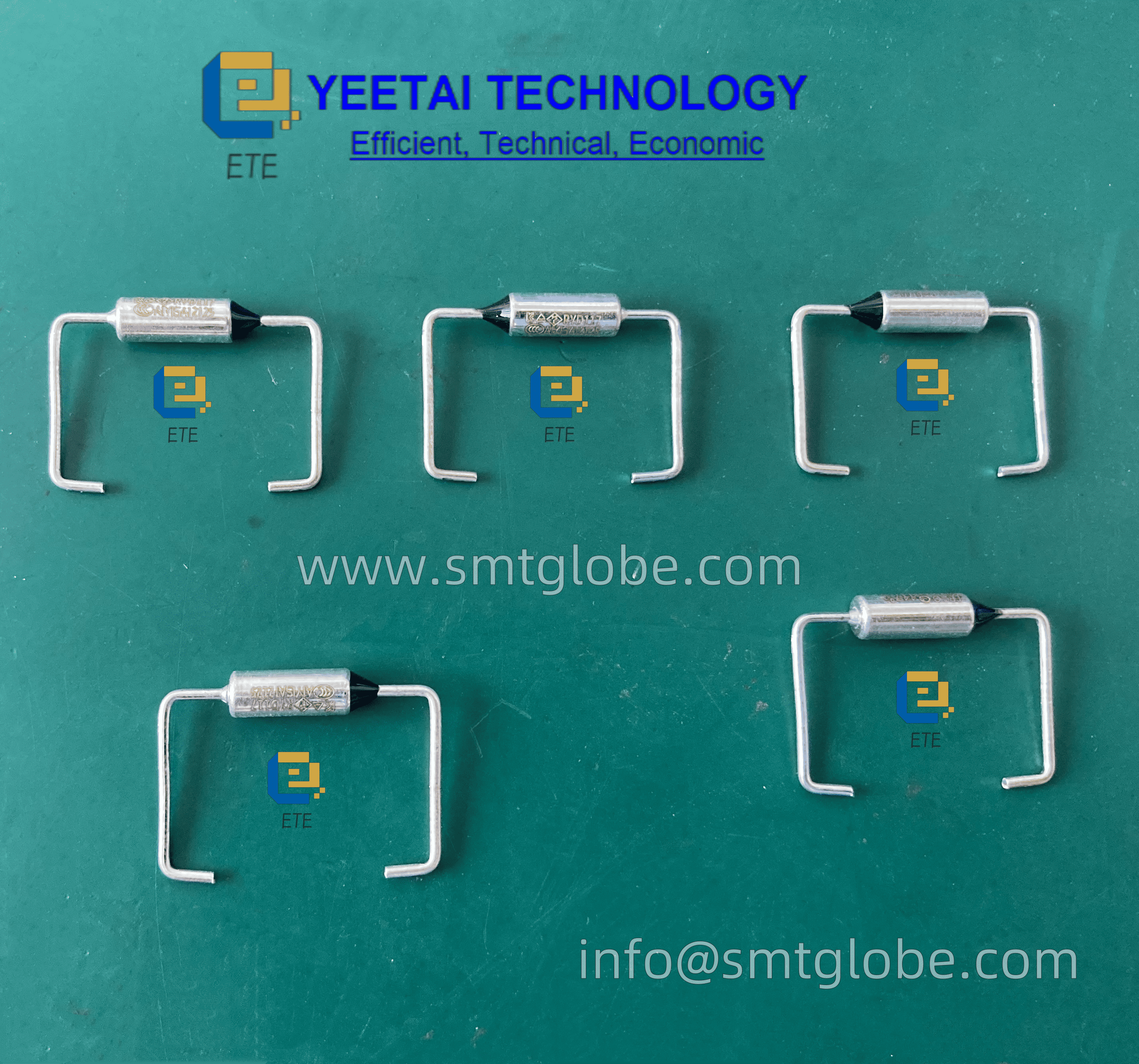

Our Axial Tape Feeder ETE-AT01 is a highly automated component feeding solution specifically designed for the Surface Mount Technology (SMT) industry. Tailored for handling axial components—such as resistors and diodes—packed in reel tapes, this feeder enhances efficiency and flexibility in PCB assembly.

Key Features of Axial Tape Feeder ETE-AT01:

- Automated Functionality

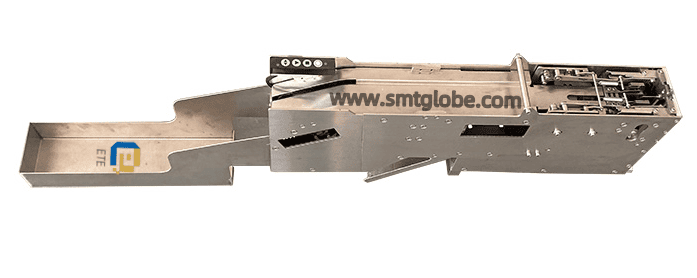

Equipped with automated guides and sensors, the ETE-AT01 integrates seamlessly with modern pick-and-place equipment. And it streamlines the component feeding process. - Compact Design

Its compact footprint allows the feeder to fit effortlessly into existing SMT lines. Optimizing space on feeder racks and enhancing workspace organization. - Broad Compatibility

The ETE-AT01 is compatible with a wide range of pick-and-place machines, including leading brands such as Fuji, Juki, Panasonic, Yamaha, Siemens, and Samsung. This adaptability makes it suitable for diverse production environments. - Versatile Feeding and Cutting Functions

The axial tape feeder not only feeds components but also offers cutting capabilities, making it a comprehensive tool for automatic assembly processes. - Enhanced Operational Efficiency

Our feeder supports various components packed in axial reel tape, featuring remote control and rapid operation to improve productivity. - Automation of Non-Standard Equipment

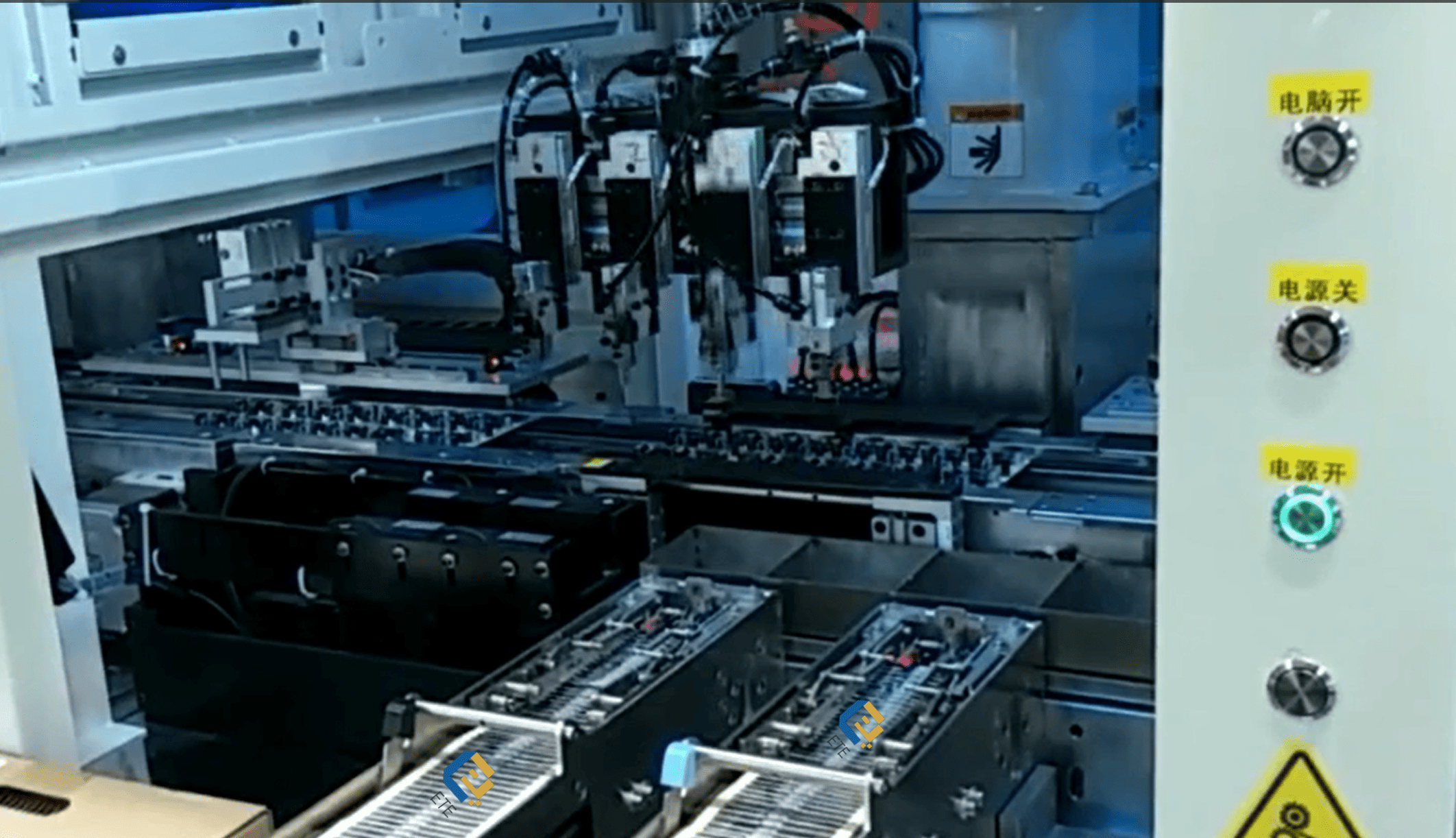

You can mount it on various placement machines or adapted for similar equipment. And it helps to reduce manual labor and improve the utilization rate of existing machinery. - Application in Relay Assembly

It effectively facilitates automatic U-shaping and leg cutting when applied in relay assembly applications. - Integration with Robotic Systems

When combined with mechanical arms, it automates production tasks that would typically require manual intervention. - Special Processing Capabilities

The feeder can process a variety of components, including axial resistors, triodes, and tape-packed jumpers etc. A versatile addition to any assembly line. - Customizable Options You can choose between various paper tape return methods and decide whether to print K position information, further tailoring the feeder’s functionality to their specific needs.

Specification Axial Tape Feeder ETE-AT01

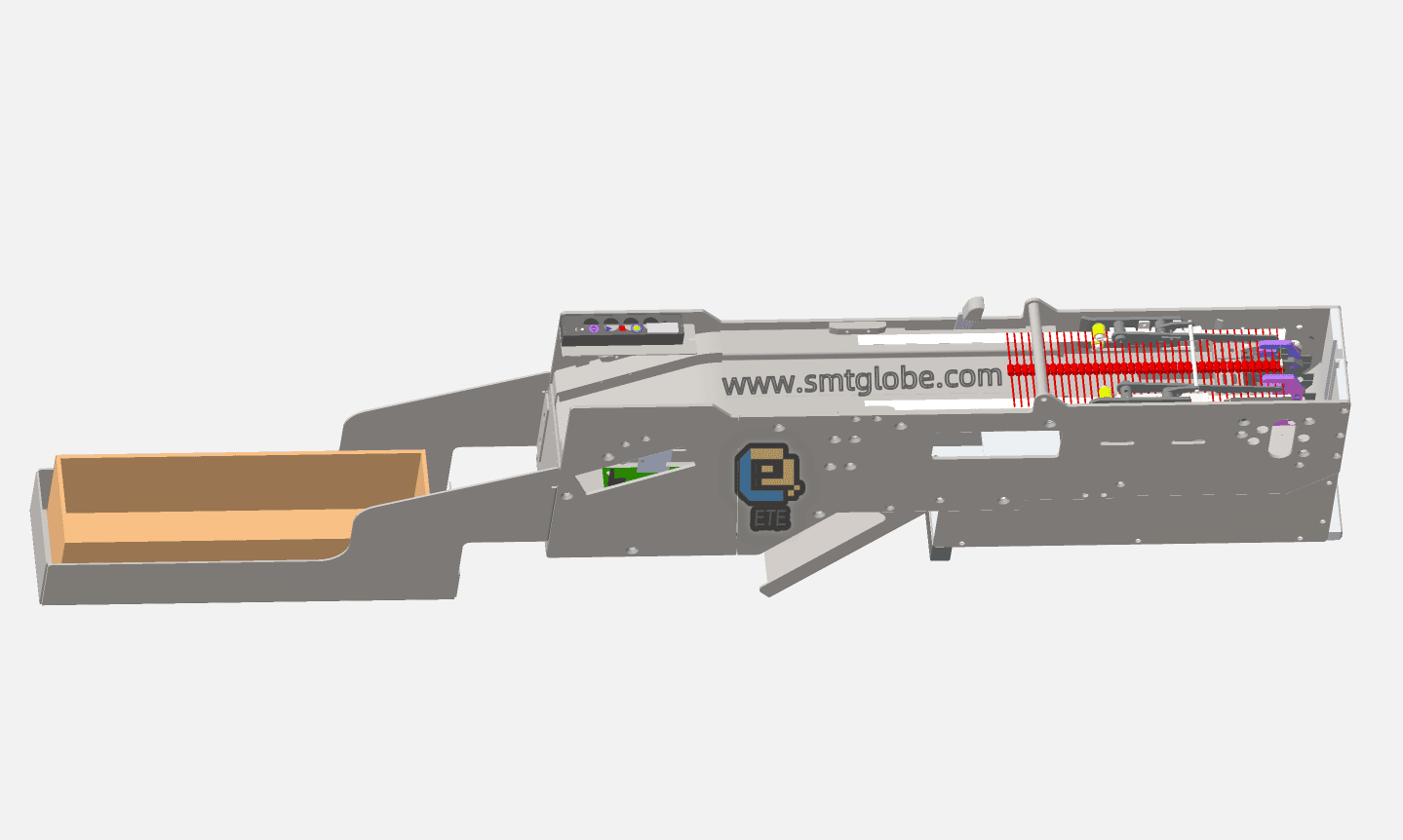

| Dimensions | length x width x height | 730x95x212mm |

| weight | 8Kg | |

| Applicable materials | Material type | Braided resistors, braided transistors, braided jumpers |

| material size | 3x3mm-6x20mm | |

| Material tape width | 35mm, 64mm, 92mm (customized according to different widths) | |

| Tape thickness | >0.2mm | |

| Structural part | Feeding method | Horizontal braiding material, boxed material |

| Feeding power | Cylinder push forward | |

| Material positioning method | Optical fiber sensing + cylinder fine-tuning | |

| a fixed way | Positioning key + pressing block, supporting other fixed structures | |

| waste paper tape recycling | vertical drop | |

| Electrical part | Operating Voltage | 24V |

| Average Current/Peak Current | 1A/3A | |

| working pressure | 0.4-0.6Mpa | |

| Operation method | key operation | |

| Host computer connection | 8 core ø16mm aviation plug | |

| communication method | Support IO communication or self-control without communication | |

| software control | Based on PLC development | |

| drive mode | The electromagnetic valve | |

| Feeding part | Feeding speed | 0.8S |

| speed gear | Pneumatic speed regulation | |

| Feeding accuracy | ±0.3mm | |

| Test record | Feed test | Realize 1000 times of continuous feeding without exception |

| Aging test | Continuous operation for 48 hours without exception | |

| service life | 5 years service life | |

| Cutter life | 5 million times cutter life |

Other feeder models ma help you.