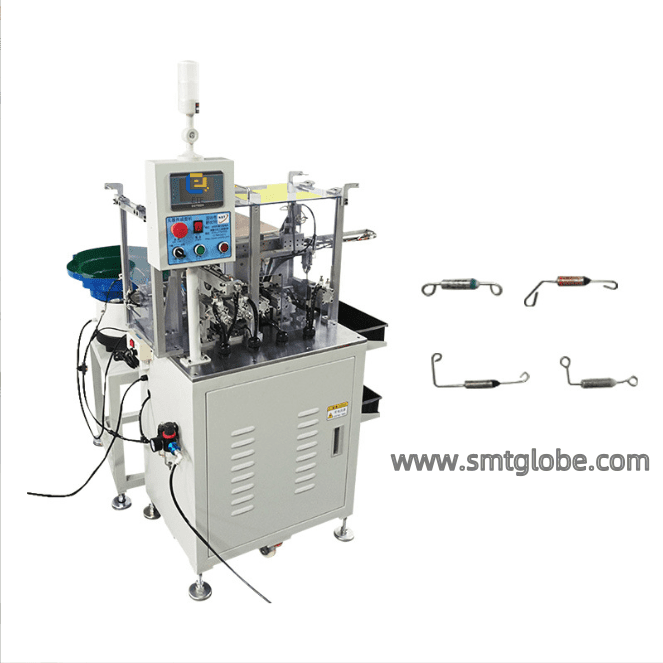

Axial lead former EAF-400 is suitable for processing loose thermal fuse. It is a bending machine that shape the component into a circle. The fuse forming machine EAF-400 controlled by a PLC program. Easy to operate and adjust according to user needs. No tooling required. The axial lead former has functions such as automatic feeding, adjustable ring height, and adjustable cut length. It has the ability to cut 1500PCS per hour.

Equipment Configuration and Parameters:

Tool material: Japan SKD11

Sheet metal process: high temperature powder spraying / surface anode / hard chromium

Power supply: 220VAC

Gas source: 5-7mpa

Overall dimension: L950xW550xH850mm

Weight: 125Kg

Processing efficiency: about 1500PCS / H;

Key Features of Axial Lead Former EAF-400

- PLC-Controlled Operation

The EAF-400 is governed by a user-friendly PLC program, making it easy to operate and adjust according to specific user requirements without the need for additional tooling. - High Processing Capacity

Capable of processing up to 1500 components per hour, the EAF-400 is ideal for mass production, ensuring consistent quality and performance. - Automatic Feeding and Adjustable Settings

This axial lead former features automatic feeding, adjustable ring height, and customizable cut lengths, allowing for precise adjustments tailored to different applications. - Intuitive Touch Screen Interface

Equipped with a touch screen human-machine interface, users can easily set production quantities and outputs. The machine automatically halts production upon reaching the preset output, ensuring efficiency and minimizing waste. - Smart Alarm Functions

The EAF-400 includes material shortage and blocking alarms, along with photoelectric induction for intelligent control of the vibration plate feeder, enhancing operational reliability. - Durable Tooling

The cutting tools are crafted from special steel and undergo high-temperature powder spraying or hard chromium treatment, ensuring durability and aesthetic appeal. This treatment guarantees long service life and consistent accuracy.

Versatile Applications

The Axial Lead Former EAF-400 is versatile and applicable for forming and cutting the leads of:

- Resistors

- Diodes

- Thermal fuses

- Other axial components

Its robust design enables the machine to complete both forming and cutting in a single operational cycle, making it a valuable addition for manufacturers seeking improved productivity and quality control.

Customizable Tooling Options

Recognizing the diverse needs of our customers, the EAF-400 offers customizable tooling options that can be tailored to meet specific production requirements, providing flexibility and adaptability in various manufacturing environments.

Why Choose the EAF-400?

Investing in the Axial Lead Former EAF-400 means opting for precision, efficiency, and reliability in your production processes. Renowned brands supply the motor and electrical components, further ensuring performance consistency and durability.

For additional information about the EAF-400, or to explore our range of lead cutters and formers, please visit our website.