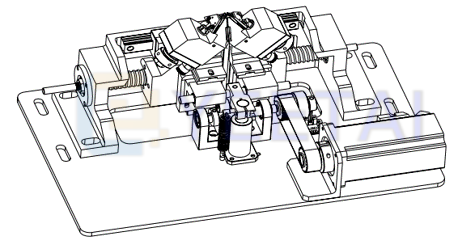

E8040 Offline Axial Insertion Machine: Streamlining PCB Component Insertion

Our E8040 Offline Axial Insertion Machine is a state-of-the-art solution designed for independent operation in PCB manufacturing. This machine automates the insertion of components supplied on tape into printed circuit boards (PCBs), significantly enhancing production efficiency and product quality.

Key Features of E8040 Offline Axial Insertion Machine

- Independent Servo Control Systems

- The E8040 features independent servo control systems. It ensures high stability and performance during component insertion. Achieving precise results even at high speeds and densities.

- User-Friendly Application Software

- Operating on a Windows XP system, the machine’s application software offers a simple and intuitive interface that enhances human-machine interaction.

- Three Main Functions

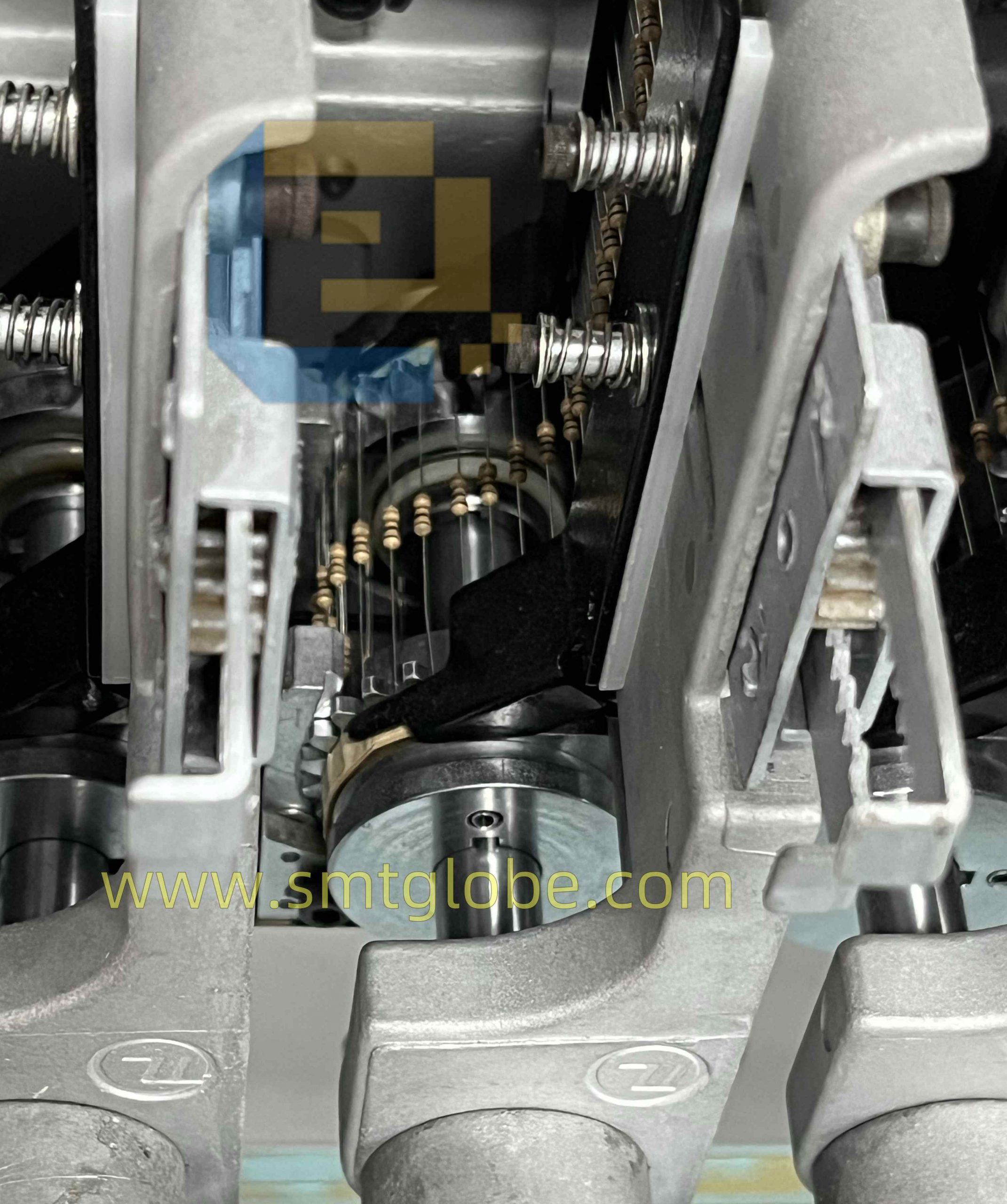

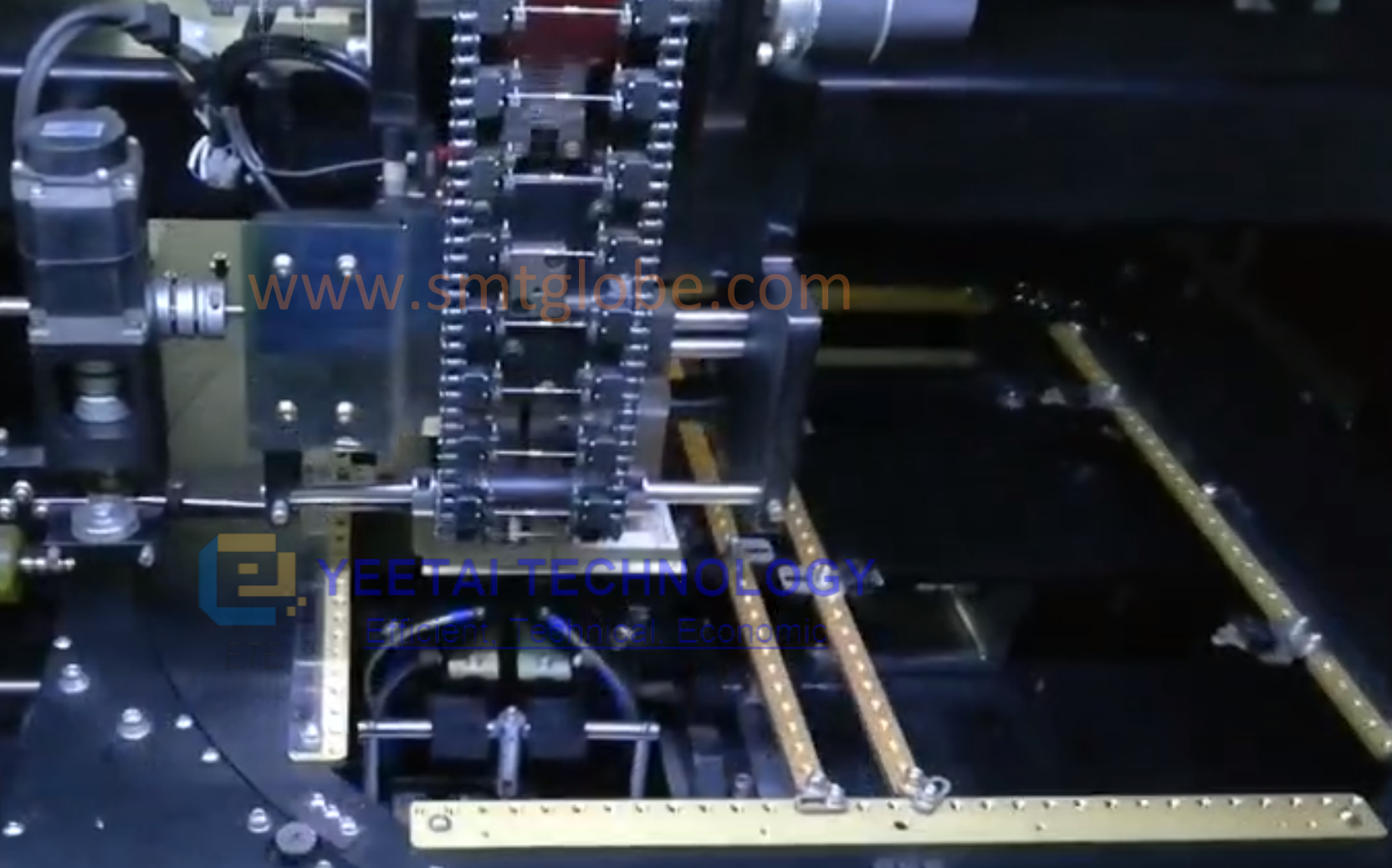

- Component Sequencing and Feeding: The axial insertion machine utilizes a distribution head to cut and place axial components from reels or trays onto a sorting chain. The sequence is controlled by a predefined product program, determining the insertion position and direction.

- Component Insertion: Custom product programs, containing information on components and processing requirements, enable the machine to start operations efficiently.

- Component Lead Cutting and Forming: After full insertion, the machine mechanically cuts and clinches component pins to secure them to the PCB, ensuring completion of the insertion process.

Notes: This machine requires manual PCB loading and unloading.

Specification

| Machine model | E8040 |

| Theoretical speed | 24,000 components/hour |

| Insertion direction | Parallel 0 degrees, 90 degrees, 180 degrees, 270 degrees |

| Lead Span | Double hole spacing 5-20mm |

| PCB Size | Minimum 50*50mm; Maximum 450*450mm |

| PCB Thickness | 0.79-2.36mm |

| Component Type | Capacitors, transistors, diodes, resistors, fusible wires, etc. Braided tape encapsulation material |

| Jumper wire | Independent conveying method. Diameter 0.5mm-0.8mm tinned copper wire |

| Component Lead Cutout Length | 1.2mm-2.2mm (adjustable) |

| Component Lead Angle | 5-35 degrees (adjustable) |

| Machine Dimension (L*W*H) | Main machine 1700mm*1500mm*1800mm ;feeding station 2100mm*1000mm*1410mm(20 stations) |

| Machine Weight | Weight of main machine 2100KG;Weight of sub-machine 480KG |

| Power Supply/Power Used | 220V,Ac(single-phase)50/60Hz,1.5KVA/1.6Kw(energy-saving type) |

| System protection | Built-in ( USP) power failure protection power supply |

| Use of air pressure (air consumption) | 0.4-0.6Mpa/0.3 cubic meters/minute(dry gas) |

| Ambient Temperature | 5-25 degrees |

| Machine noise | 65dB |

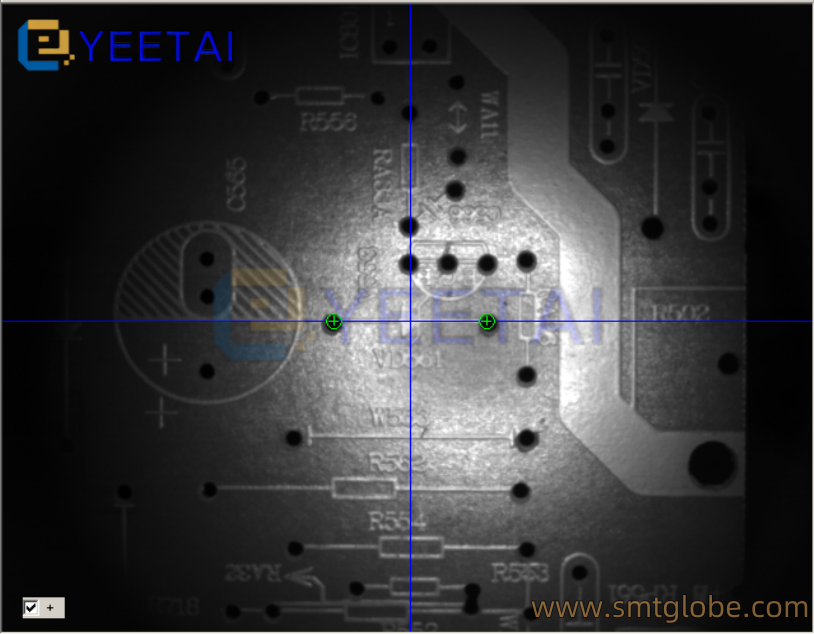

| Hole correction method | Machine vision system, multi-point MARK vision correction |

| Drive system | AC servo, AC motor |

| Data input method | USB interface input (EXCEL file format) |

| Control system | Chinese operation interface (WINDOWS XP system control platform) LCD monitor |

| Table operation method | Clockwise and counterclockwise |

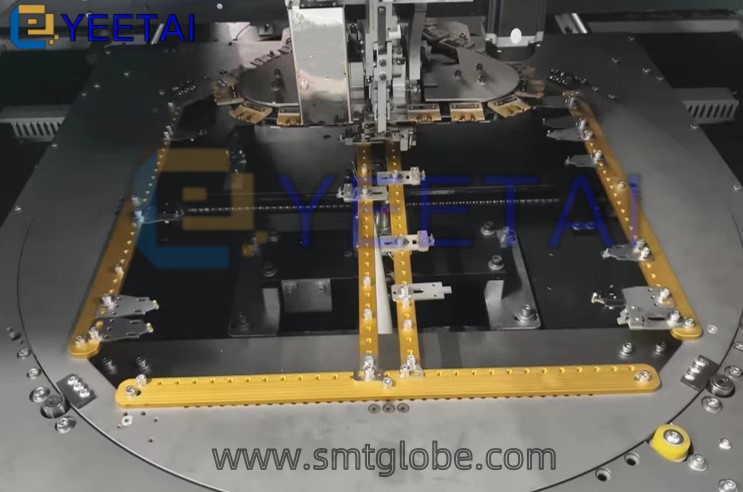

| PCB loading method | Manual |

Performance and Reliability

- The E8040 sets an industry benchmark with a remarkable throughput of 24,000 components per hour (CPH), accompanied by a reliability rating of 300 parts per million (ppm).

- Its programmable clinch height adjusts to safeguard against damaging surface-mount device (SMD) components, ensuring that component value and polarity are verified before insertion.

Enhanced Features of E8040 Offline Axial Insertion Machine

- Rotary Table: This machine incorporates a rotary table design, equipped with long-life tools and low-profile locators that reduce wear and extend operational lifespan.

- Low Maintenance and User-Friendly Programming: The machine’s design minimizes maintenance needs, supported by a USB port for easy data transfer and Gerber format file input.

- Built-in Power Failure Protection (USP): This feature allows component replenishment without interrupting operations, promoting continuous productivity.

- Dual-Part Detection: The machine can detect two parts on the chain simultaneously, enhancing operational efficiency.

Advantages of the E8040 Axial Insertion Machine

- Automated Operations: Reduces reliance on manual labor through automated processes.

- High-Speed Performance: Achieves theoretical speeds of 24,000 components per hour.

- Consistent Stability: Simple operation with high stability ensures consistent performance.

- Flexible Production Capabilities: Versatile and adaptable for various production needs.

- Cost-Effective Operation: Low maintenance costs contribute to overall efficiency and profitability.

- Wide range of material applicable: Our machine can insert both axial components and jumper wires.

Machine Operation Instructions

Operating Environment

- Optimal operating conditions: Temperature: 5-25°C, Humidity: 20-95%, with no direct sunlight, condensation, or exposure to water, oil, or chemicals.

Safety Guidelines

- Maintain clear space at the front and back of the machine for operation and maintenance.

- The technician must be computer literate and trained to operate and repair the machine.

Computer Usage

- The dedicated computer for the machine is strictly for this purpose and must not be used for other applications. Avoid connecting any unverified devices to prevent system damage.

- The USB flash drive provided must be virus-free and should not be used on other computers.

Operational Safety Precautions

- Do not open the front and back doors during operation or reach into the machine without proper safety measures.

- Avoid repeatedly turning the power on and off; wait at least 20 seconds before restarting after shutdown.

- Prevent impacts or strong vibrations, as these may result in machine breakdown.

Shutdown Procedure

- To safely turn off the machine, follow this sequence: exit the application program, exit Windows, then turn off the power. Failing to follow this sequence can lead to data loss and potential damage to the hard disk.

Temporary Shutdown Instructions

- If temporarily halting use, maintain the machine in an environment with Temperature: 5-25°C, Humidity: 20-95%, away from sunlight and moisture. Dust covers are advisable, but they must ensure moisture protection.

Contact Us for More Information

For more details about the E8040 Offline Axial Insertion Machine or to obtain operational support, please contact us. Our experts are ready to assist you in enhancing your PCB manufacturing efficiency!

If you need more other insertion machines, welcome to our website or click below.