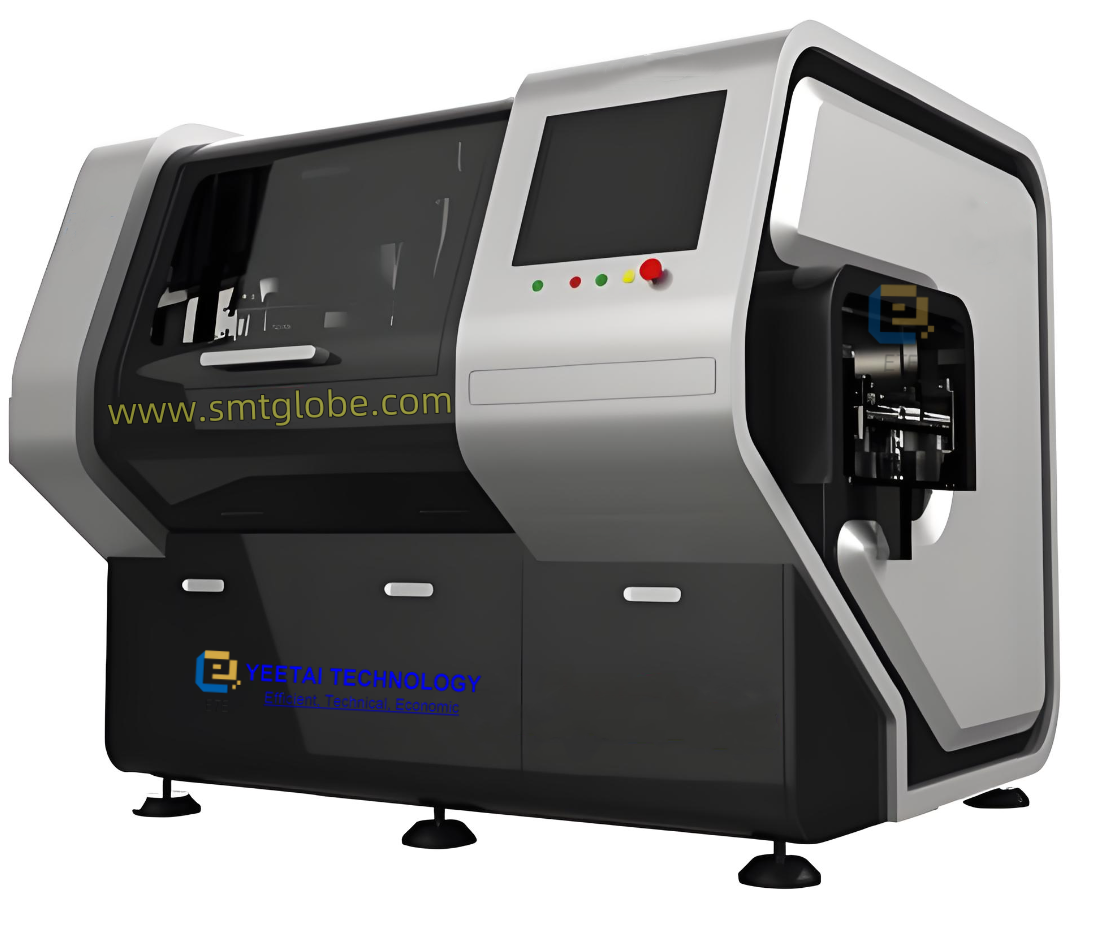

E4420 Inline Axial Component Inserter: Automating PCB Assembly

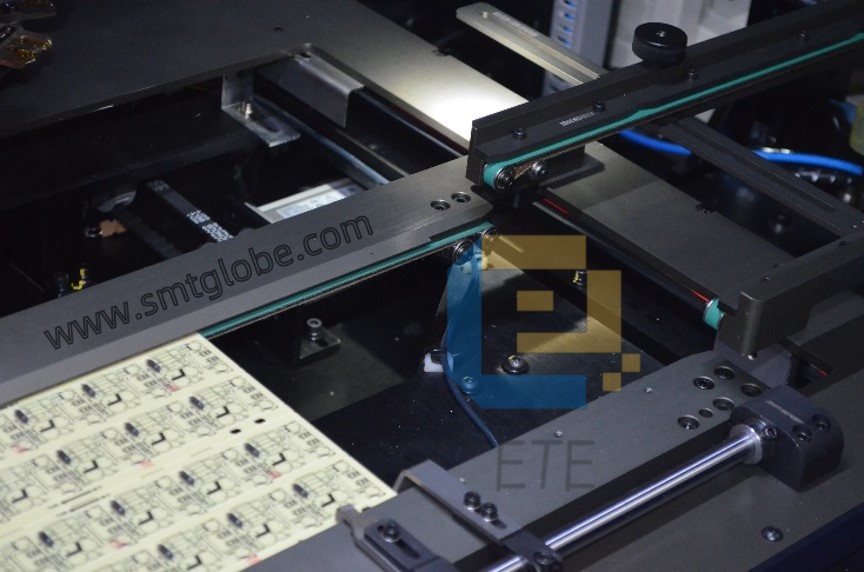

Our E4420 Inline Axial Component Inserter revolutionizes PCB assembly with its advanced board handling system that automates the loading and unloading of printed circuit boards (PCBs). Designed for high-volume operations, this machine effortlessly inserts components supplied on tape, enhancing efficiency and product quality.

Key Features

- Independent Servo Control Systems

- The E4420 comes with multiple independent servo control systems, ensuring high stability and optimal performance during component insertion, even at high speeds and densities.

- User-Friendly Application Software

- Built on the Windows XP platform, the application software offers an intuitive interface that facilitates seamless human-machine interaction, enhancing operational efficiency.

- Four Core Functions

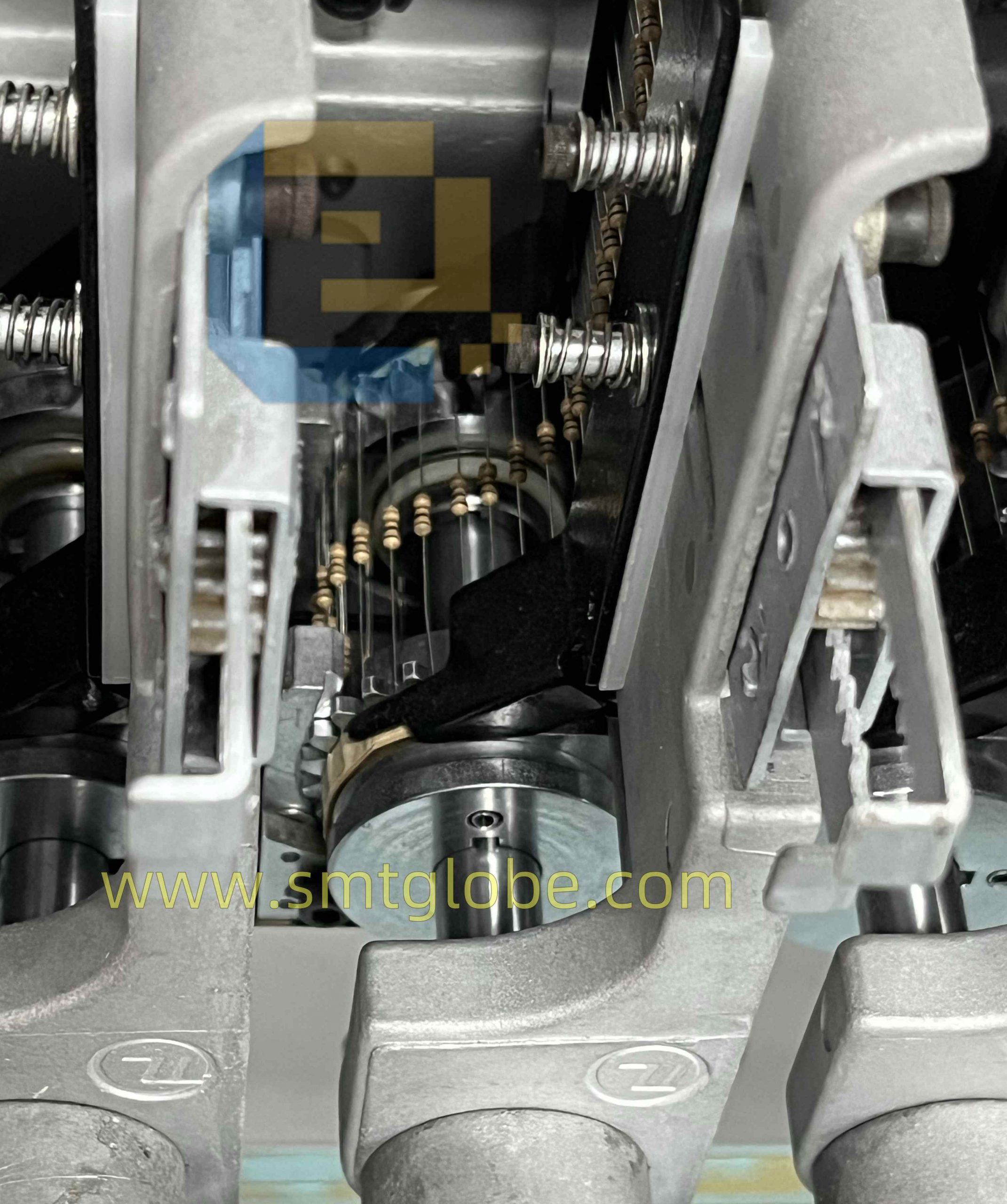

- Component Sequencing: A distribution head cuts axial components from reels or boxes and places them on a sorting chain. The sequence is determined by a pre-set product program, controlling the positioning and direction of component insertion.

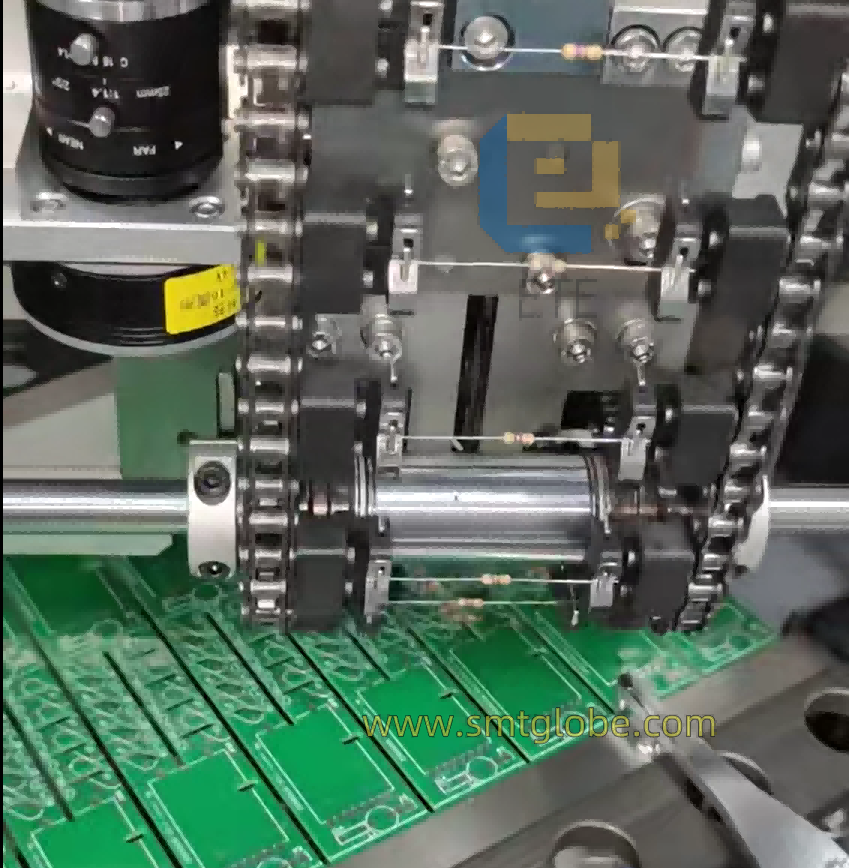

- PCB Loading and Unloading: The machine automatically loads PCBs onto the working table and unloads completed assemblies to adjacent machines. This continuous operation minimizes the need for operator intervention.

Component Insertion: Tailored product programs encompass all necessary information regarding components and processing requirements, allowing for the efficient initiation of operations.

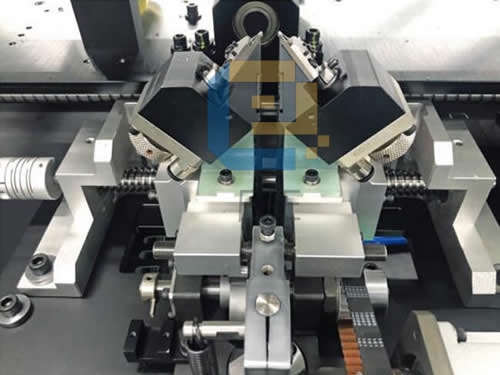

Component Pin Cutting and Forming: After insertion, the cutting and clinching unit secures the component pins to the PCB, ensuring a complete assembly before removal.

Specification

| Machine model | |

| Theoretical speed | 24,000 components/hour |

| Insertion direction | Parallel 0 degrees, 90 degrees, 180 degrees, 270 degrees |

| Lead Span | Double hole spacing 5-20mm |

| Substrate Size | Minimum 50*50mm; Maximum 320*400mm |

| Substrate Thickness | 0.79-2.36mm |

| Component Type | Capacitors, transistors, diodes, resistors, fusible wires, etc. Braided tape encapsulation material |

| Jumper | Independent conveying method. Diameter 0.5mm-0.8mm tinned copper wire |

| Component Lead Cutout Length | 1.2mm-2.2mm (adjustable) |

| Component Lead Angle | 5-35 degrees (adjustable) |

| Machine Dimension (L*W*H) | Main machine 1700mm*1500mm*1800mm ; feeding station 1200mm*1000mm*1410mm(20 stations) |

| Machine Weight | Weight of main machine 1200KG;Weight of sub-machine 800KG |

| Power Supply/Power Used | 220V,Ac(single-phase)50/60Hz,1.5KVA/1.6Kw(energy-saving type) |

| System protection | Built-in ( USP) power failure protection power supply |

| Use of air pressure (air consumption) | 0.4-0.6Mpa/0.3 cubic meters/minute(dry gas) |

| Ambient Temperature | 5-25 degrees |

| Machine noise | 65dB |

| Hole correction method | Machine vision system, multi-point MARK vision correction |

| Drive system | AC servo, AC motor |

| Data input method | USB interface input (EXCEL file format) |

| Control system | Chinese operation interface (WINDOWS XP system control platform) LCD monitor |

| Table operation method | Clockwise and counterclockwise |

| PCB loading method | Automatic, from left to right or right to left |

Enhanced Performance

- The E4420 is designed with an optional freely rotating platform that meets the process requirements for inserting components at any angle up to 360 degrees, significantly minimizing operational bottlenecks and manual interventions.

- Utilizing a 45-degree V-shaped forming tool, the machine reduces mechanical stress on component structures, maintaining reliability by keeping tensile interference minimal.

Efficiency and Reliability

- The intelligent modular feeder is compact yet robust, capable of achieving an impressive throughput of 24,000 components per hour (CPH). It can be expanded to accommodate up to 80 stations to meet evolving production demands.

- With proprietary tooling and an efficient feeding drive structure, the E4420 ensures zero jumper lead scrap during operation. This flexibility allows it to handle a comprehensive range of axial lead components and jumper wire diameters in a single pass.

Automated Handling

- The automatic board handling system enables uninterrupted machine operation by facilitating automated PCB loading and unloading. This system significantly benefits high-volume manufacturing environments with low to moderate job changeovers. The axial inserter is also SMEMA compatible.

Advance Quality Assurance

- The programmable clinch height feature safeguards against damage to surface-mount device (SMD) components while verifying component value and polarity before insertion.

- Additional features include built-in power failure protection (USP) and dual-part detection capabilities, enhancing the machine’s operational reliability.

Advantages of the E4420 Axial Component Inserter

- Automation: Minimizes manual labor through automated operation.

- High-Speed Production: Achieves a theoretical maximum of 24,000 components per hour.

- Stable Operation: Offers consistent performance with user-friendly controls.

- Flexible Production: Adapts to diverse production needs with versatile capabilities.

- Cost-Effective Maintenance: Low maintenance costs ensure an economical operational lifecycle.

User Interface and Control

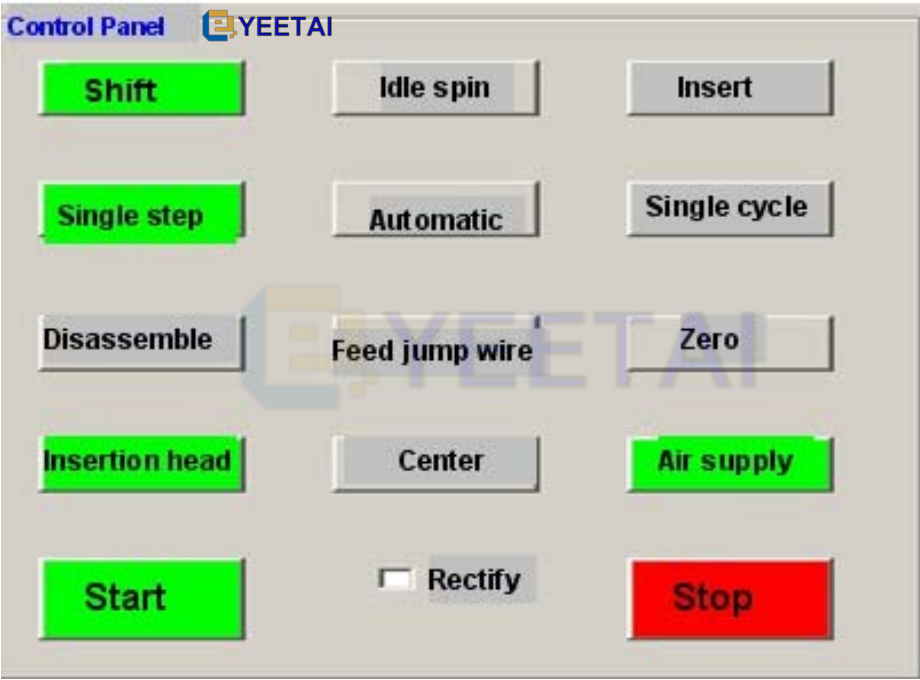

User Interface

- The E4420 utilizes a standard PC motherboard, allowing for easy data management. Operators can control the machine via a color flat-panel display, keyboard, and trackball, with an optional touchscreen interface available for enhanced usability.

Operator Button Panel

- The operator panel provides essential controls for production runs. Functions can also be accessed through the graphical user interface. It includes USB port access for convenient file transfer.

Contact Us Today!

For more information on the E4420 Inline Axial Component Inserter and how it can elevate your PCB assembly process, contact us. Our experts are ready to assist with your automation needs and ensure you achieve maximum production efficiency!

If you need more other insertion machines, welcome to our website or click below.