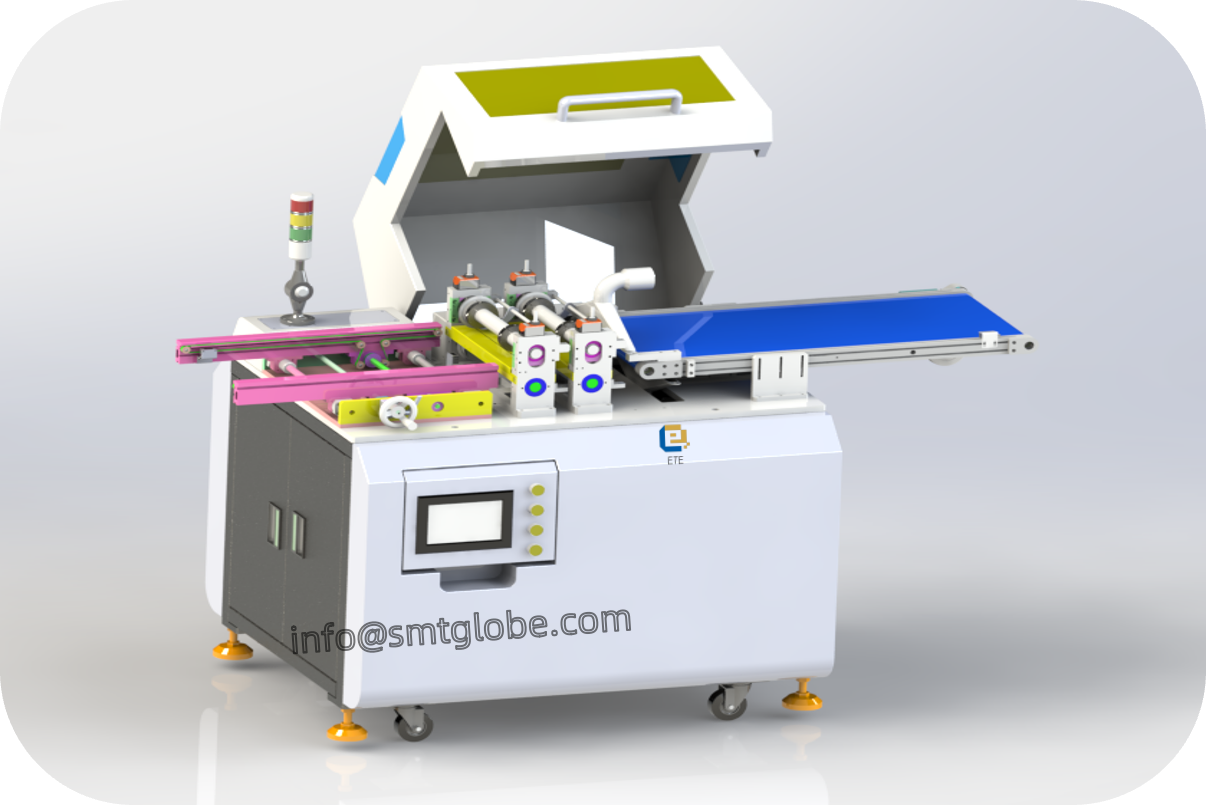

Our Automatic PCB Separator is the perfect solution for efficient and versatile depanelization of PCB and LED panel. With its modular design, the equipment can easily switch between different board types, offering high precision and productivity. The machine’s practicality, versatility, and customization options make it an ideal choice for meeting diverse customer needs. With manual feeding and belt discharge, it ensures seamless operation and high UPH (units per hour). Explore our range of automatic PCB separator for your PCB and LED strip board separation needs.

Automatic PCB Separator can achieve one-time full board separation:

- Automatic PCB Separator can be connected to upper and lower board machines to realize unmanned operation.

- With easy installation and simple operation settings.

- Saves labor, time, and effort.

- Small footprint, efficient and quick operation.

- The Automatic PCB Separator is divided into different series models based on the number of modules at the time of shipment: ① One module: ETE-510 ② Two modules: ETE-520 ③ Three modules: ETE-530

- Recommended selection: ① 0-500mm, recommended for fiberglass board and aluminum substrate: ETE-510; ② 500-900mm, recommended for fiberglass board and aluminum substrate: ETE-520; ③ ≥900mm, recommended for fiberglass board and aluminum substrate: CY-530.

Features:

- Equipment versatility: The Automatic PCB Separator is designed to cater to the cutting requirements of both PCBA products and LED products, offering a wide range of applications and adaptability to various production needs.

- Multi-functional feeding: This machine is equipped with the capability to perform both online separation and manual feeding, providing flexibility in the production process and accommodating different operational preferences.

- High efficiency operation: The PCB Separator excels in high-efficiency operations, ensuring swift and precise separations with minimal downtime, thereby enhancing overall productivity and output.

- Simple changeover and rewiring: With a modular design for blade modules, the machine facilitates easy and quick switching between different configurations. The entire blade module can be replaced at once, simplifying changeovers and minimizing setup time.

- Board loading: The process of loading boards onto the machine is carried out manually, allowing for careful placement and alignment to ensure smooth operation and accurate cutting.

- Depanelization: The Automatic PCB Separator automates the material separation process, streamlining production and minimizing manual intervention for efficient and consistent results.

- Versatility: The machine offers the flexibility to manually add or remove blade modules as needed, enabling customization based on specific product requirements and ensuring adaptability to diverse production scenarios.

- Discharge: Finished products are discharged using a belt system for automated handling, while manual collection is also possible for specific applications, providing options for efficient product retrieval and workflow management.

- UPH: ① PCBA: about 5s for one board assembly, approximately 2500 pcs (small board) Product deviation: 100 pcs ② LED strip board: about 10s for one board assembly, approximately 3500 pcs (small board) Product deviation: 100 pcs

- Number of required operators: 1 person