Automatic PCB Flipper: Enhancing Efficiency in Double-Sided PCB Processing

The Automatic PCB Flipper inverts PCBs (Printed Circuit Boards) by 180°. This enables efficient handling for double-sided processes. Our machine has fast, smooth, and precise inverting motion. It ensures optimal positioning and handling during production. It is essential for double-sided PCB operations. The flipper allows for smooth transitions between the top and bottom sides of the board. Significantly improving productivity and precision in SMT (Surface Mount Technology) factories.

Key Features

Pneumatic Stoppers:

Equipped with pneumatic stoppers. The Automatic PCB Flipper securely positions PCBs during the flipping process. Ensuring stability and accuracy.

Adjustable Conveyor:

The conveyor accommodates varying PCB widths. Provides versatility for different production needs.

PLC Control:

With programmable logic controller (PLC) technology, maintenance is simplified. We offer you efficient operation management.

By-Pass Mode:

The selectable by-pass mode offers flexibility in production workflows. Thus, you can adapt to varying processing requirements.

Fast and Precise Motion:

The device features a fast and precise inverting motion. Our machine can enhance overall efficiency in PCB handling.

Compact Design:

With a space-saving machine footprint, the Automatic PCB Flipper fits seamlessly into existing production environments.

SMEMA Compatibility:

Fully compatible with SMEMA (Surface Mount Equipment Manufacturers Association) standards. Easy integration with existing SMT production lines.

User-Friendly Touchscreen Display:

The touchscreen interface provides intuitive operation. Our machine includes automatic fault diagnosis for quick troubleshooting.

Multiple Alarm Functions:

Equipped with various alarm functions to alert operators of any issues. This enhances operational safety and reliability.

Transport Rail Compatibility:

The transport rail is compatible with 10mm high fixtures. Facilitating versatile PCB handling.

Adjustable Flipping Speed:

Features adjustable flipping speed settings. Prevents PCB slippage during the inverting process.

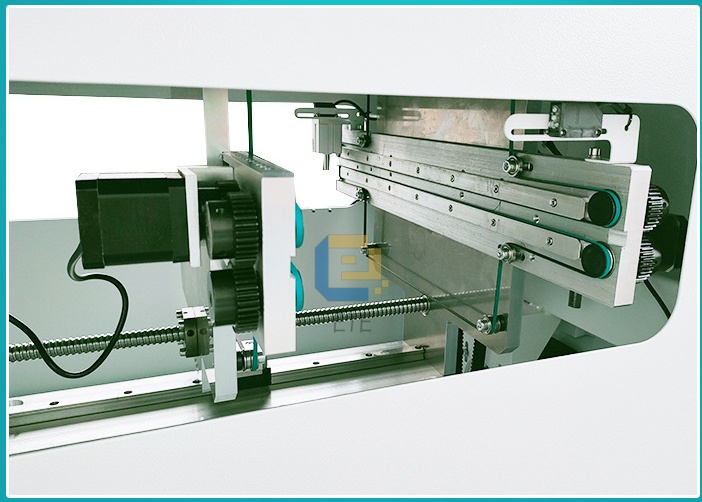

Stepper Motor Transmission:

The inclusion of a stepper motor and gear drive allows for precise adjustment of the transmission speed. Can meet the needs of diverse SMT production lines.

Specification

| Model | EFC-250 | EFC -330 | EFC -390 | EFC -460 |

| PCB Size | 50*50-350*250 | 50*50-460*330 | 50*50-530*390 | 50*50-530*460 |

| Machine Size | 500*705*1250 | 500*785*1250 | 600*845*1250 | 600*915*1250 |

| Weight | 150kg | 165kg | 180kg | 190kg |

| PCB Thickness (mm) | 0.6-3mm | |||

| Transport Height | 900±20 (or Customer specify) | |||

| PCB Transport Direction | L→R or R→L | |||

| Transport Carrier | ESD Belt or Chain (Selectable) | |||

| Cycle Time | About 5s | |||

| Power supply and electrical load | 100-230VAC (user specified), single phase, 250 VA maximum | |||

| Air pressure and air flow | 4-6bar, up to 10 l/min | |||

| Starting power/no-load power | 250W | |||

| Control Panel | Samkoon 4.3-inch full-color touch screen control panel. | |||

| Stopper | Cylinder CDQ2B20*40 | |||

| Triple light | Warning red light with buzzer, yellow light and green light in one | |||

| Control method | Panasonic PLC | |||

| Drive mode | Stepper Motor | |||

If you need other PCB board handling equipment, we can also help. Find them as below.