Automatic Glue Dispensing Machine: Precision and Efficiency Redefined

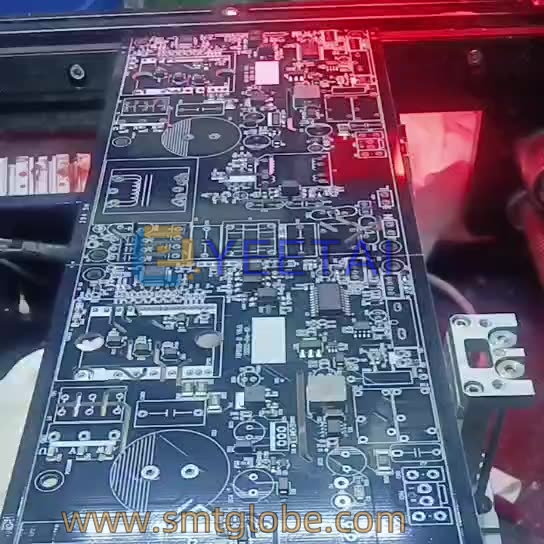

Introducing our Automatic Glue Dispensing Machine, a cutting-edge solution designed for precision glue dispensing and filling. Engineered to provide high-speed, precise application, this machine utilizes a jet-style quantitative supply method, eliminating the need for Z-axis movement during operation. This breakthrough technology addresses common challenges faced in traditional dispensing methods, such as sharp tip formation, uneven glue application, and potential damage to components. By maximizing work efficiency and product quality, our machine stands out as the ideal choice for various industrial applications.

Key Features of Our Automatic Glue Dispensing Machine

- High-Speed Motion Platform: Our mature and stable design ensures reliable, high-speed performance for long-term usage.

- Non-Contact Jet Dispensing Technology: Our innovative design allows for dispensing without Z-axis movement, enhancing operational efficiency and reducing wear on components.

- Automatic Temperature Control: Maintain consistent fluidity across various materials with our automatic constant temperature system.

- Online Monitoring: Keep track of dispensing volumes in real-time to ensure accuracy and consistency.

- Seamless Integration: Our inline conveying system enables communication with other equipment, streamlining production processes.

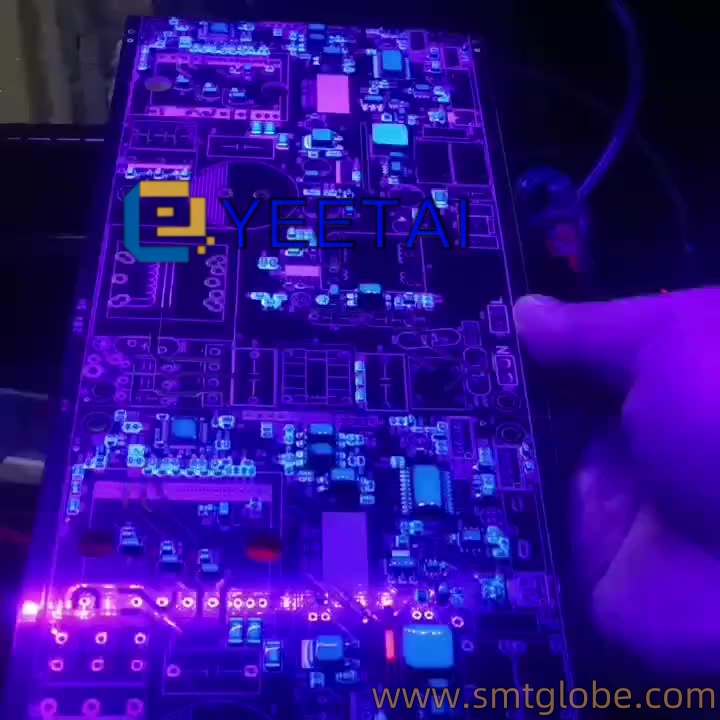

- Advanced Visual Systems: Features precise visual positioning and automatic sampling systems for quality assurance.

- Warping Tolerance: No impact from PCB warping ensures consistent application across all surfaces.

- Versatile Valve Compatibility: Compatible with various dispensing methods, including jet valves, screw valves, and pneumatic valves, offering flexibility for different applications.

- Modular Design: Customize your machine with optional functional modules tailored to your specific needs.

- High-Speed Dispensing: Capable of achieving up to 200 dots per second, maximizing productivity.

- Adjustable Dot Size: Set the minimum spray space as small as 0.18 mm for precise applications.

- Broad Application Range: With a minimum single dot diameter of 250 microns, our machine handles a wide range of adhesives with ease, including those with viscosities up to 250,000 CPS.

- Minimal Dispensing Amount: Achieve precision with a minimum single dispensing amount as low as 0.015 mg.

- Cost-Effective Performance: Designed for high performance while maintaining a competitive cost.

- Improved Consistency: Enhance dispensing consistency, reduce material waste, and eliminate sharp tip formations to increase production capacity and yield.

- User-Friendly Interface: Our intuitive control software simplifies operation and programming, making it accessible to all operators.

- Enhanced Accuracy: Includes advanced chip recognition technology for precise positioning, surpassing traditional mark point recognition systems.

- Smart Identity Recognition: Features automatic program calling, mistake-proofing mechanisms, and data collection to support intelligent manufacturing.

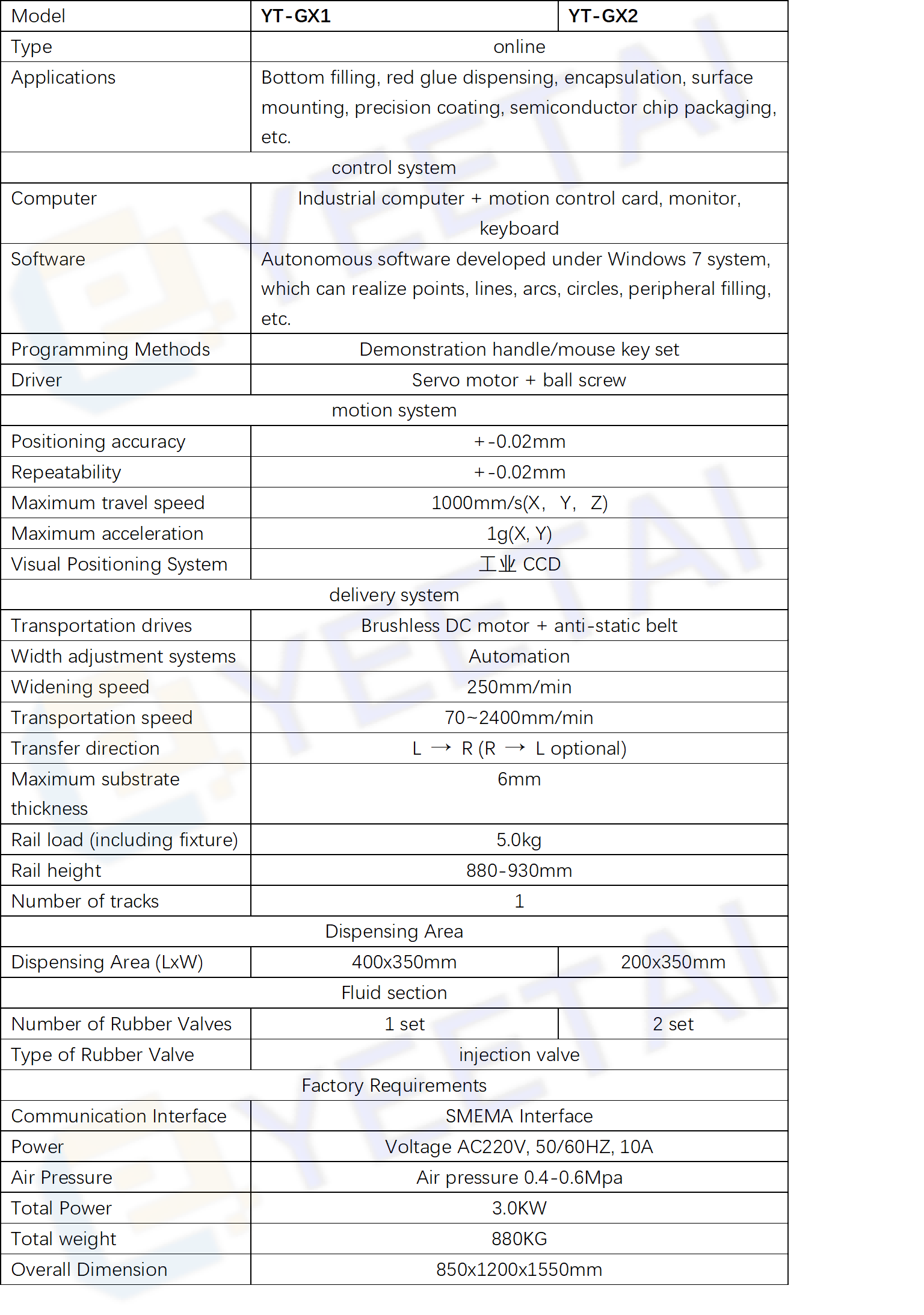

Specification

Advantages of Our Automatic Glue Dispensing Machine

- Cost Savings: Replaces traditional manual dispensing methods, significantly reducing labor costs.

- Consistency and Quality: Guarantees consistency in glue application, leading to improved PCBA production quality.

- Ideal for Mass Production: Our inline automatic glue dispensing machine is perfect for high-volume production environments, enhancing overall factory capacity.

Conclusion

Our Automatic Glue Dispensing Machine represents a leap forward in precision and efficiency for industrial applications. Whether you’re in SMT and PCB assembly, semiconductor packaging, LED packaging, or flat panel display assembly, our machine is engineered to meet your specific needs while delivering exceptional performance.

For more information on how our automatic glue dispensing machine can revolutionize your production process, contact us today!