Tube Feeder ETE-TF01 automates feeding of components coming with tube packages,such as ICs, connectors, and transistors etc. Improve efficiency, reduce labor costs, and maximize the utility of your SMT line. Our component feeding equipment is customizable,so you can use our feeders to deliver various components to different SMT machines.Explore our tube feeder’s technical specifications and features now.

Features

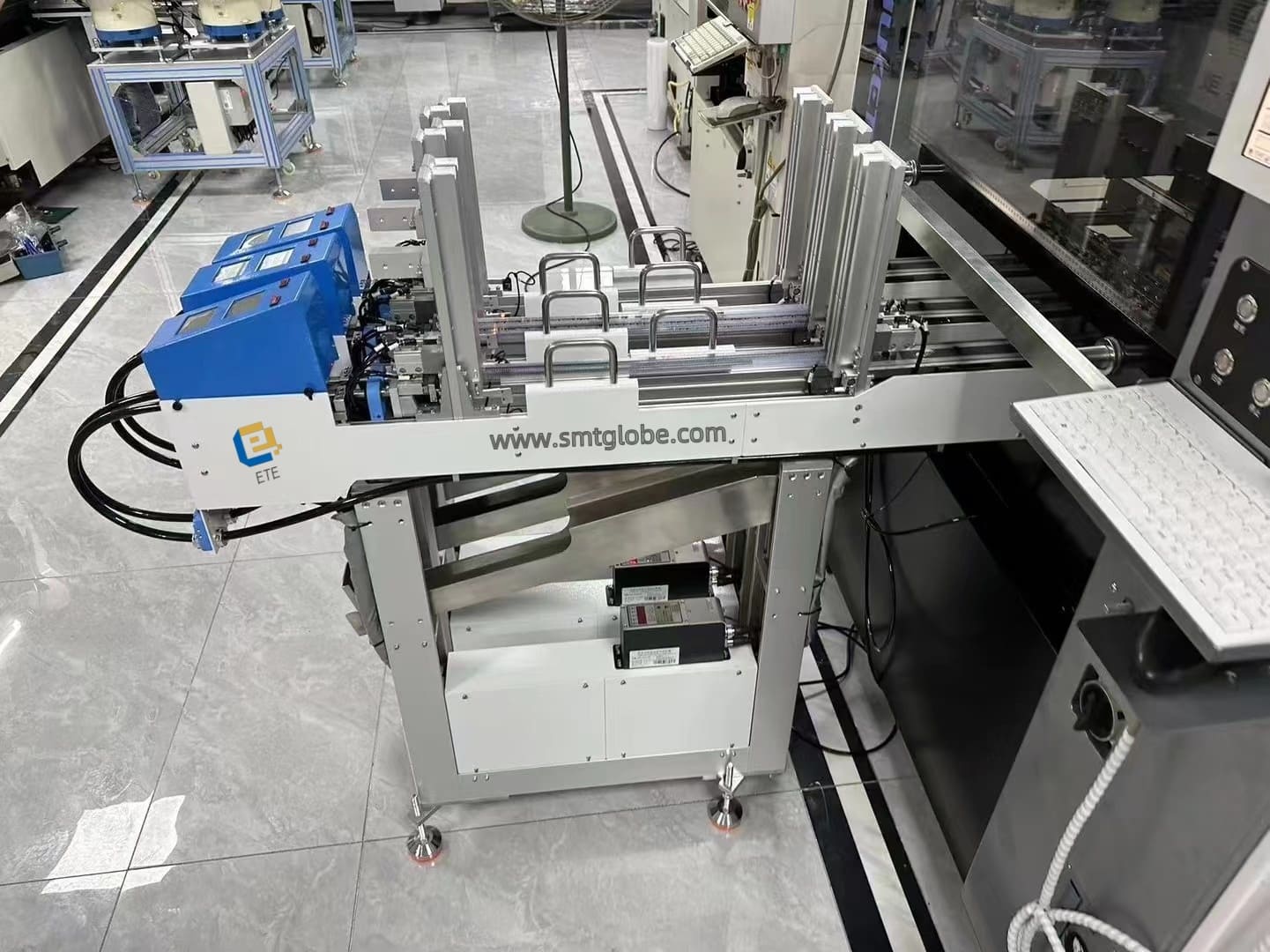

1: Put all kinds of tube-packed materials of DIP insertion on various types of pick and place machines. It offers automatic insertion, cuts down labor cost, and improves the utilization of SMT pick and place machine.

2: Load tube-packed materials on the feeder. Or load various IC and Triodes on non-standard equipment, saving the non-standard design cycle and improving the stability of current SMT pick and place machine.

3: Apply the tube-mounted feeder to the screw lock of the triode and heat sink, and the tube-mounted feeder will automatically attach the triode.

4: The tube feeder is combined with the robotic arm to finish automatic production instead of manual operation.

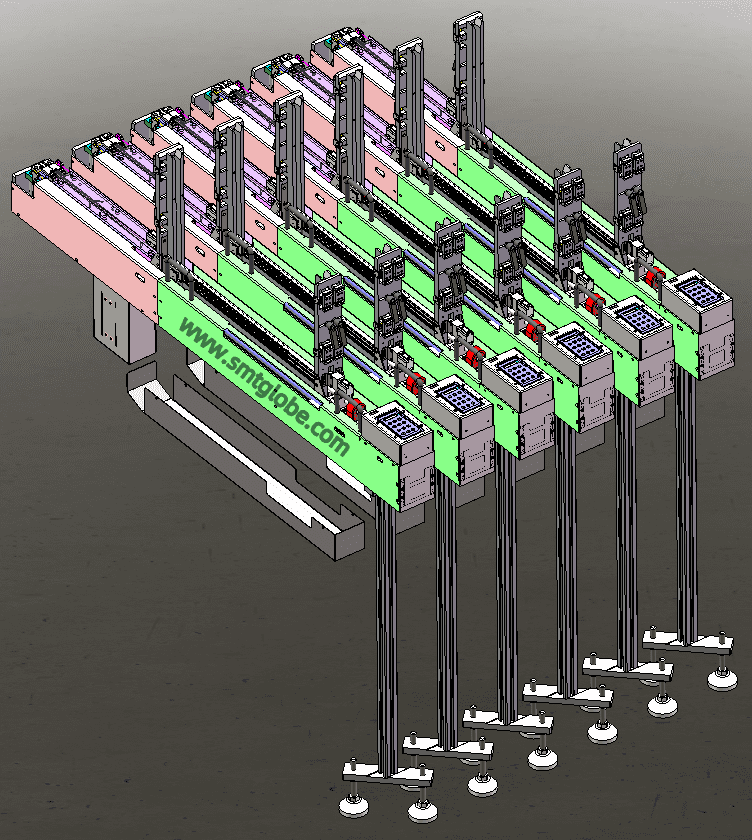

5: According to site requirements, choose tube feeders of different sizes.

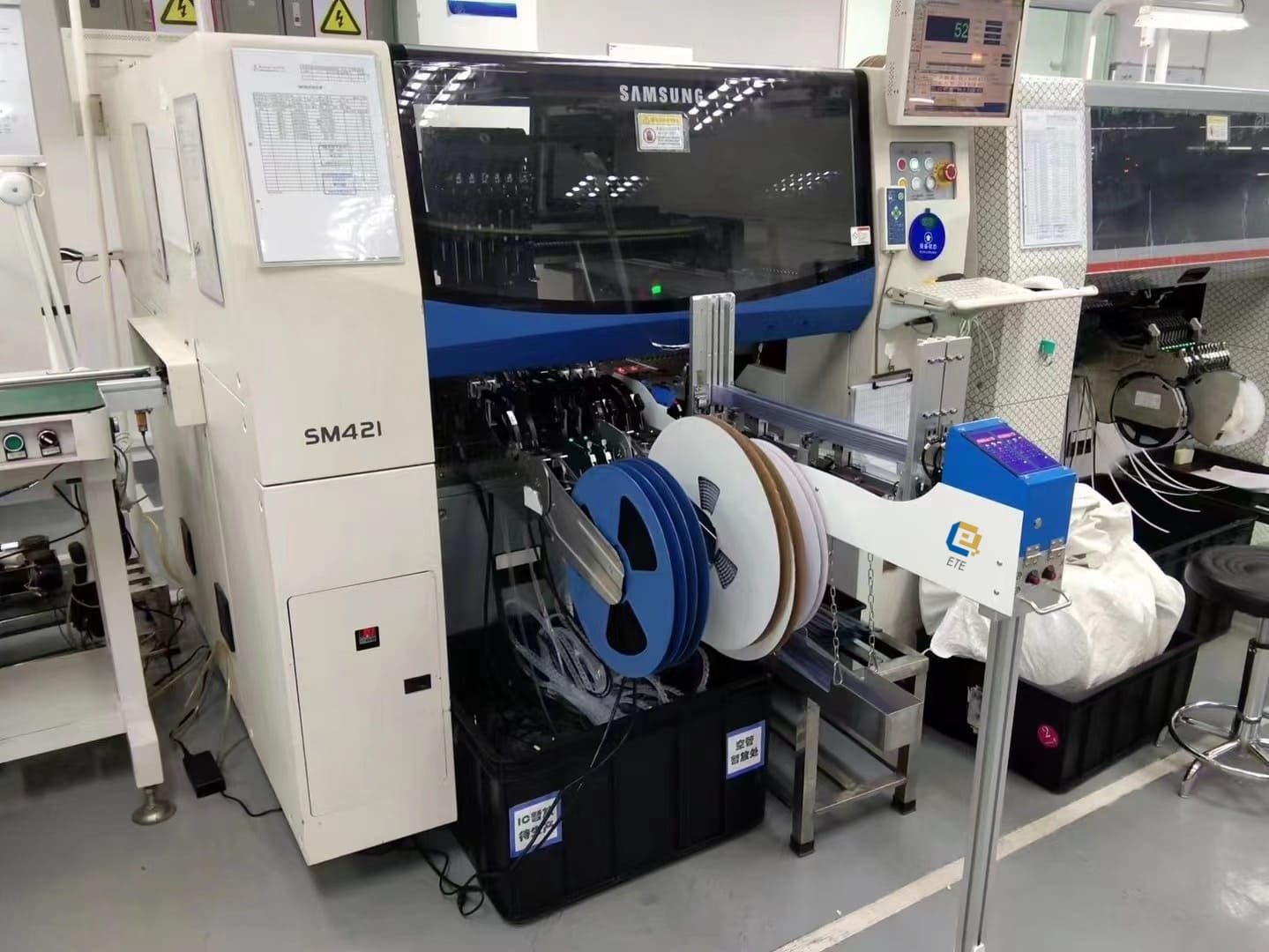

6. Support all popular machine brands, such as Fuji, Juki, Panasonic, Yamaha, Simens, Samsung and Mydata etc.

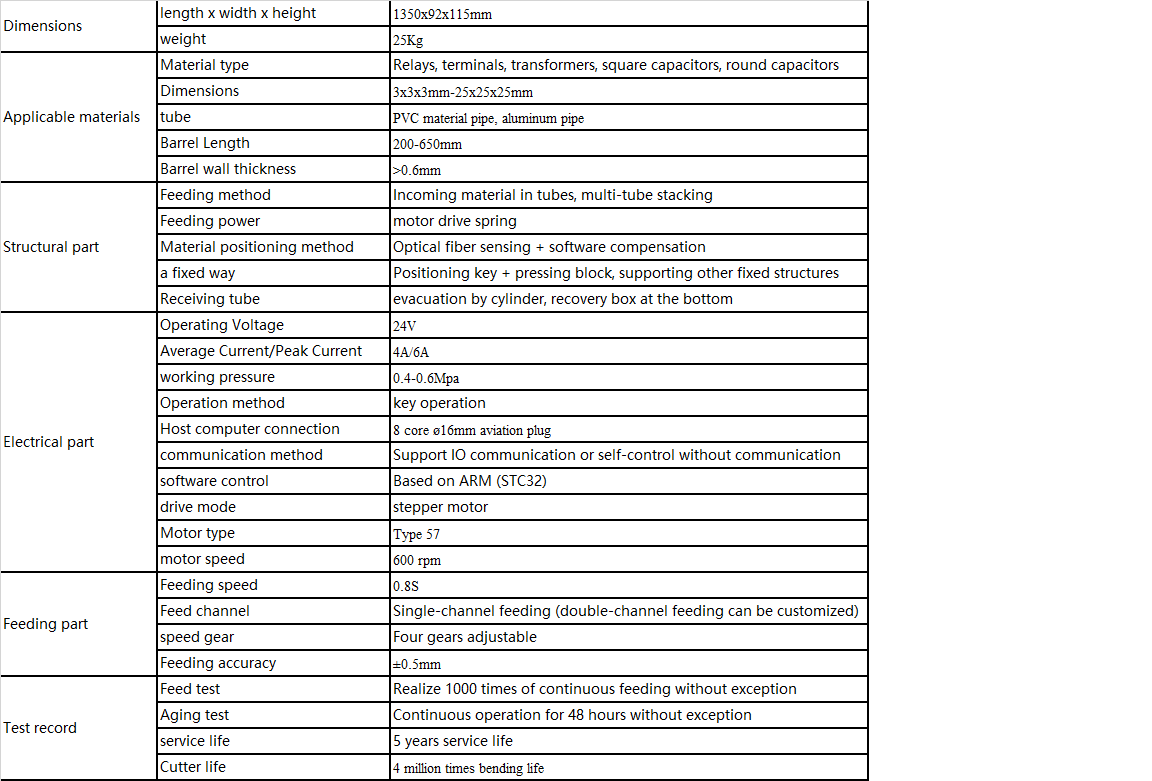

Specification

Advantages:

- Labor-saving: Automate component transport and placement, reducing the need for manual labor.

- Enhanced efficiency: Maximize the utility of your SMT line without the need for additional machinery, saving costs and streamlining operations.

- Versatile compatibility: Suitable for a wide range of tube-packed materials, including triodes, connectors, and ICs. Compatible with leading machine brands including Fuji, Juki, Panasonic, Yamaha, Siemens, Samsung, and Mydata.

- Customizable: Choose from different sizes to match your specific production requirements.

- Longevity: Built for durability with a 5-year service life and a 4-million-times bending life for the cutter.

Other feeders may help you more.