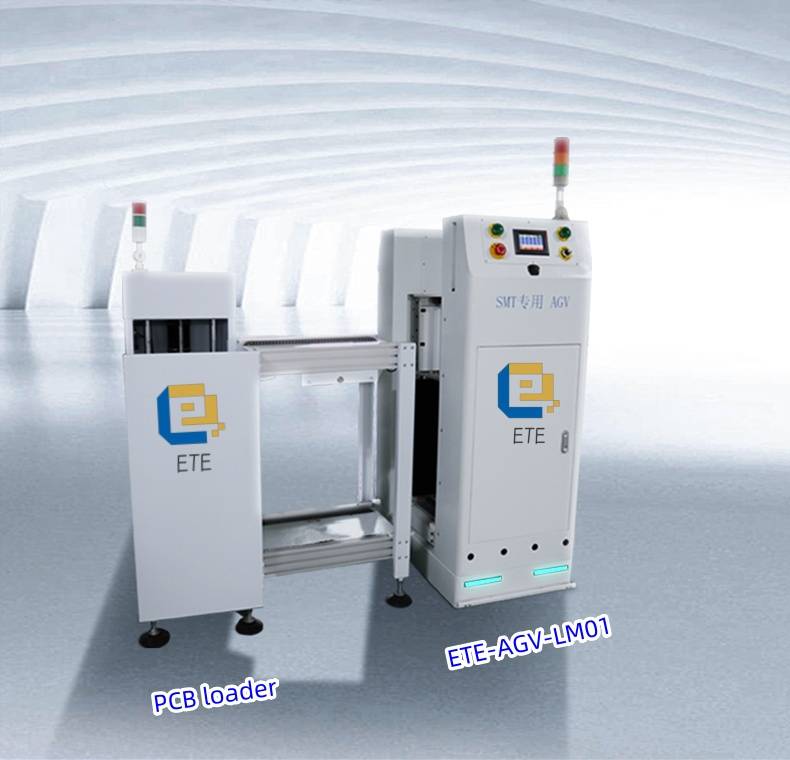

The Auto-guided Vehicle for SMT production line,moves ESD SMT magazine rack. It offers great automation for moving ESD SMT magazine rack. This SMT AGV equipment works well with SMT PCB loader.

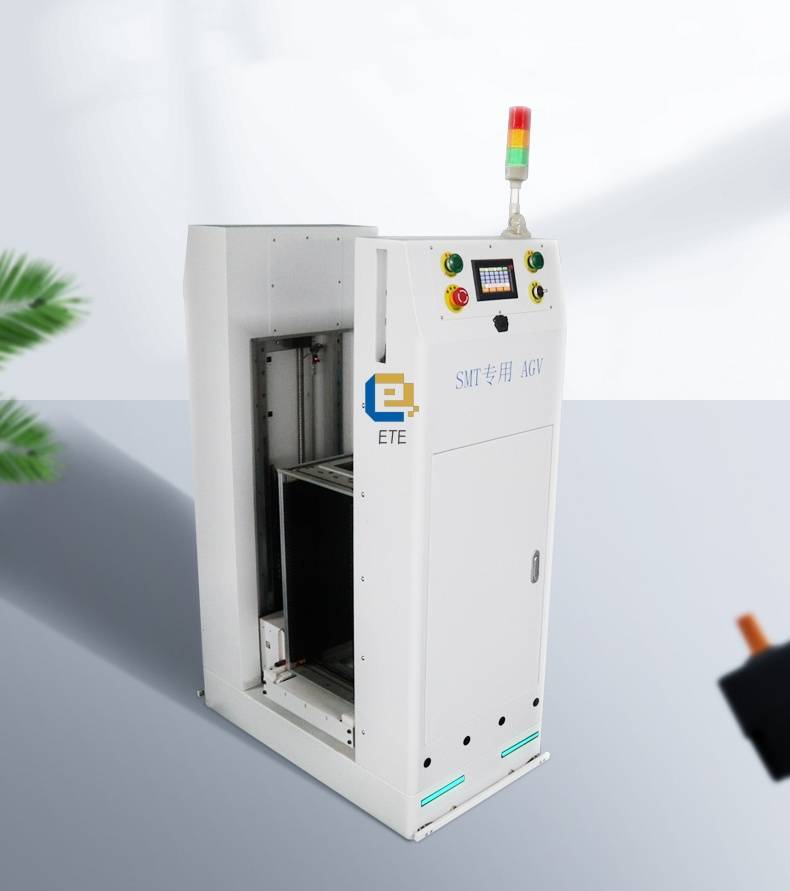

With a loading capacity of 50KG, lithium battery, and advanced navigation strip guidance, this Auto-guided Vehicle for SMT production line offers unparalleled flexibility and reliability in automated transport operations. Its features include obstacle detection, touch anti-collision switch bars, automatic route planning, which makes it an ideal solution for smart and agile production environments.

Key Features:

- 50KG loading capacity: The Auto-guided vehicle for SMT production line is equipped with a robust chassis and powerful motors, allowing it to effortlessly transport materials and components weighing up to 50KG within the production facility.

- Lithium battery with 10 hours of battery life: The vehicle is powered by a high-capacity lithium battery that provides a continuous operation time of up to 10 hours, ensuring uninterrupted workflow and minimal downtime during production cycles.

- Obstacle detection using ultrasonic radar: Utilizing advanced ultrasonic radar technology, the Auto-guided vehicle for SMT production line is capable of detecting obstacles in its path and autonomously navigating around them, enhancing safety and efficiency in the production environment.

- The vehicle features intelligent software algorithms that enable it to automatically plan the most efficient routes within the production line, optimizing material flow and minimizing transit times.

- Operators have the flexibility to customize the driving modes of the vehicle to suit different operational requirements, whether it be speed, acceleration, or maneuverability, allowing for seamless integration into various production processes.

- The vehicle is designed to accommodate and transport a wide range of ESD (Electrostatic Discharge) magazine racks commonly used in SMT production, ensuring compatibility with different types and sizes for maximum versatility.

- With its versatile design and compatibility, the vehicle can seamlessly interface with various SMT loader and unloader machines, facilitating the smooth transfer of materials and components throughout the production line.

Specification

| Model | Auto-guided Vehicle for SMT production line EAL100 |

| Navigation method | Navigation strip; can drive towards inter-direction |

| Loading capacity | 50KG |

| Driving mode | single line,circle route,remote control,branch route(customizable) |

| Max. speed | 20-40m/minute,adjustable |

| Min. Turning radius | 0.8m; can make a 90° (L type) turning |

| Stop accuracy | ±5CM |

| Battery Type | lithium battery 48V30AH |

| Battery life | 10 hours (customizable) |

| Standby time | 200 hours |

| Charging time | 5 hours |

| AGV dimension(MM) | L900 X W500 X H380 |

| Plate dimension(MM) | L355 X W320X H 656 |

| AGV weight | 80KG |

| Running indicator | LED lights both at the Front and rear; running indicator light + flashing red light when there is an obstacle |

| Drive | Brushless Motor Differential Ratio |

| Obstacle detection method | Ultrasonic radar |

| Touch anti-collision switch bar | 1 at the front and 1 at the back |

| LCD display | 4.3-inch high-definition touch screen |

| Automatic Route Planning | Automatic Route Planning available |

| Start | Manual start + timing start + remote control start; wireless serial communication can be added to support secondary development |

| Site selection | 20 RFID Cards |

| Charging method | DC charging / battery charging |

| Remaining power indicator | auto-alarm in case of power shortage |

| Spare part | 20m navigation strips,20 RFID Cards,6 deceleration cards,4 obstacle avoiding cards,10 terminal strips,5A charger |

| Warranty | 1 year |

Our company is dedicated to the development and manufacturing of intelligent sensor-guided Auto-guided Vehicle for SMT production line, tugger AGV transport vehicles, and AGV for automatic loading and unloading machine. Through continuous technological innovation, we have cultivated a highly skilled design team with extensive experience. We collaborate comprehensively with customers to provide effective solutions tailored to their needs, ultimately enhancing their production efficiency. We strive to offer robust technical support to a wide range of manufacturing industry clients.

We also have other AGV robots.