Absolutely, the use of anti-static products is vital in modern manufacturing environments, especially in industries dealing with sensitive electronic components. We have been supplying this products for years. We aim to help our customers to build a qualified and secured SMT factory. Here’s a breakdown of how anti-static products can enhance production efficiency:

Benefits of Anti-Static Products

- Protection of Electronic Components:

- Reduction of Damage: Static electricity can cause significant harm to electronic parts, leading to malfunctions or failures. Anti-static products, such as ESD magazine racks, and ESD PCB storage trolley, effectively mitigate this risk.

- Minimizing Downtime:

- Prevention of Production Halts: Static discharges can result in equipment shutdowns, which disrupt the production flow. By employing high-quality anti-static solutions, manufacturers can minimize the likelihood of such incidents and maintain continuous operations.

- Enhanced Equipment Reliability:

- Decreased Equipment Failure: Regular use of anti-static measures helps maintain equipment integrity, reducing the frequency of repairs and replacements. This contributes to a more reliable production environment.

- Improved Product Quality:

- Decrease in Scrap and Waste: With lower static-related failures, the rate of product defects diminishes, leading to less material waste and higher overall quality in finished goods.

- Increased Worker Safety:

- Safer Working Environment: Anti-static measures not only protect products and equipment but also contribute to a safer workplace. Employees can work without the fear of accidental static discharge, which can cause discomfort or injury.

- Cost Efficiency:

- Long-Term Savings: Although there is an initial investment in anti-static products, the reduction in downtime, equipment failures, and product waste leads to cost savings over time, improving overall profitability.

Examples of Anti-Static Products

- Anti-Static Workbenches: These surfaces are designed to dissipate static electricity, protecting sensitive components during assembly or testing.

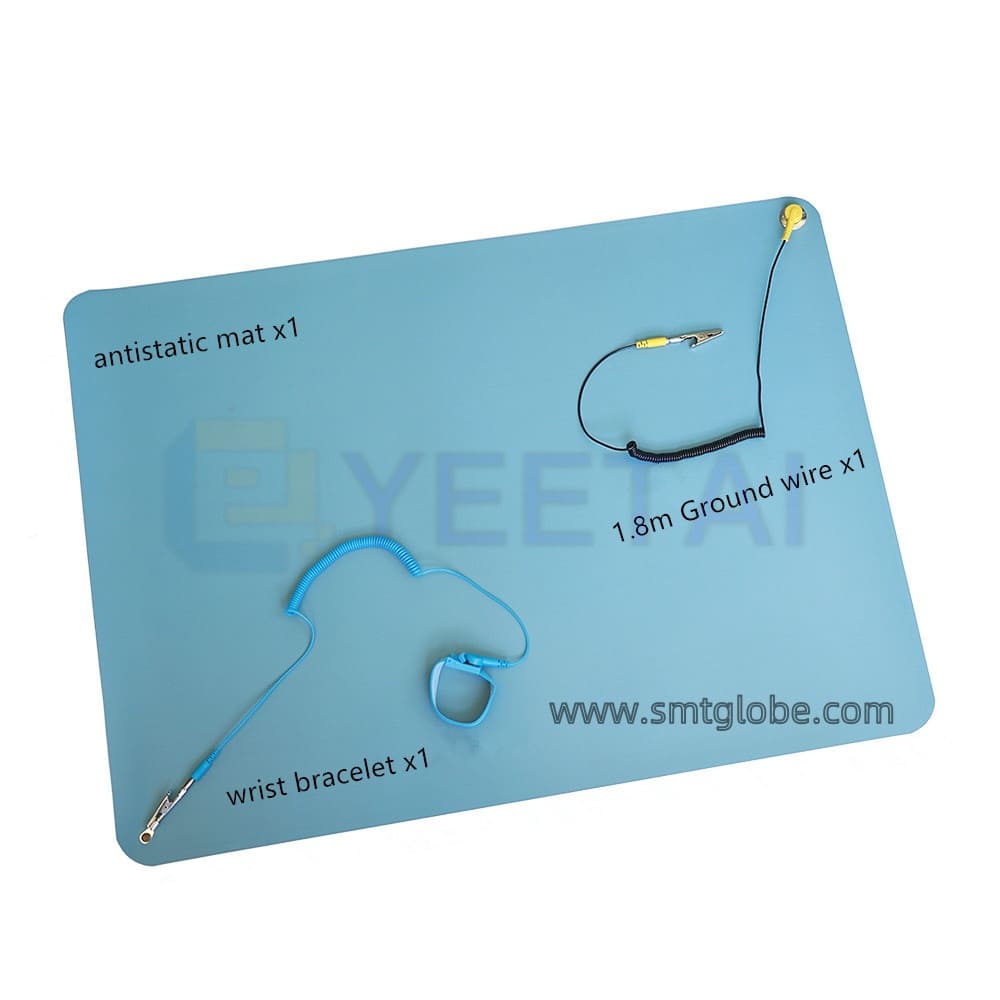

- Anti-Static Mats: Placed on workstations or floors, these mats help prevent the buildup of static charges.

- ESD (Electrostatic Discharge) Safe Storage Solutions: Including anti-static bins, turnover boxes, and shelving, which ensure safe storage and handling of sensitive components.

- Wrist Straps and Grounding Devices: Wearable products that help to ground personnel, preventing static buildup while working with electronics.

Conclusion

Implementing anti-static products is an essential aspect of modern manufacturing that not only enhances the stability and continuity of production lines but also protects equipment and products from static-related damage. By investing in high-quality ESD solutions, manufacturers can significantly boost their operational efficiency and product quality.

If you want to enhance your ESD management, you can learn more knowledge in our website. We keep sharing more skills and useful products. Get started now!