Our AGV Robot Wave Soldering Pallet brings advanced automation to DIP insertion lines in SMT factories. This innovative machine efficiently moves wave soldering pallets, PCB fixtures, PCBs, and SMT stencils. It streamlines and optimizes operations on your SMT production line. With precise navigation and efficient material handling, it is the ideal solution for SMT automation.

AGV Robot Wave Soldering Pallet ETE-AGV100-K

Key Features of the AGV Robot Wave Soldering Pallet

- Increased Operational Efficiency: By automating material handling tasks, our AGV robot significantly reduces reliance on manual labor, allowing your workforce to focus on more complex tasks.

- Enhanced Safety Protocols: The integration of AGVs in industrial environments minimizes the potential for accidents and injuries caused by human error, creating a safer workplace.

- Flexible Adaptation: The machine can easily adapt to changing production needs and layouts, providing a scalable solution for dynamic manufacturing environments.

- Cost Savings: Implementing AGVs can lead to substantial cost savings over time, as they offer a cost-effective solution for repetitive material transport operations.

- Precision and Accuracy: Our AGVs ensure precise material delivery and positioning, contributing to improved overall operational efficiency and productivity.

- Seamless Integration: AGVs can be easily integrated with existing automation systems, allowing for synchronized operation within your manufacturing facility.

- Scalable Solutions: The scalability of AGVs enables businesses to adjust their fleet size and capabilities based on fluctuating workload demands.

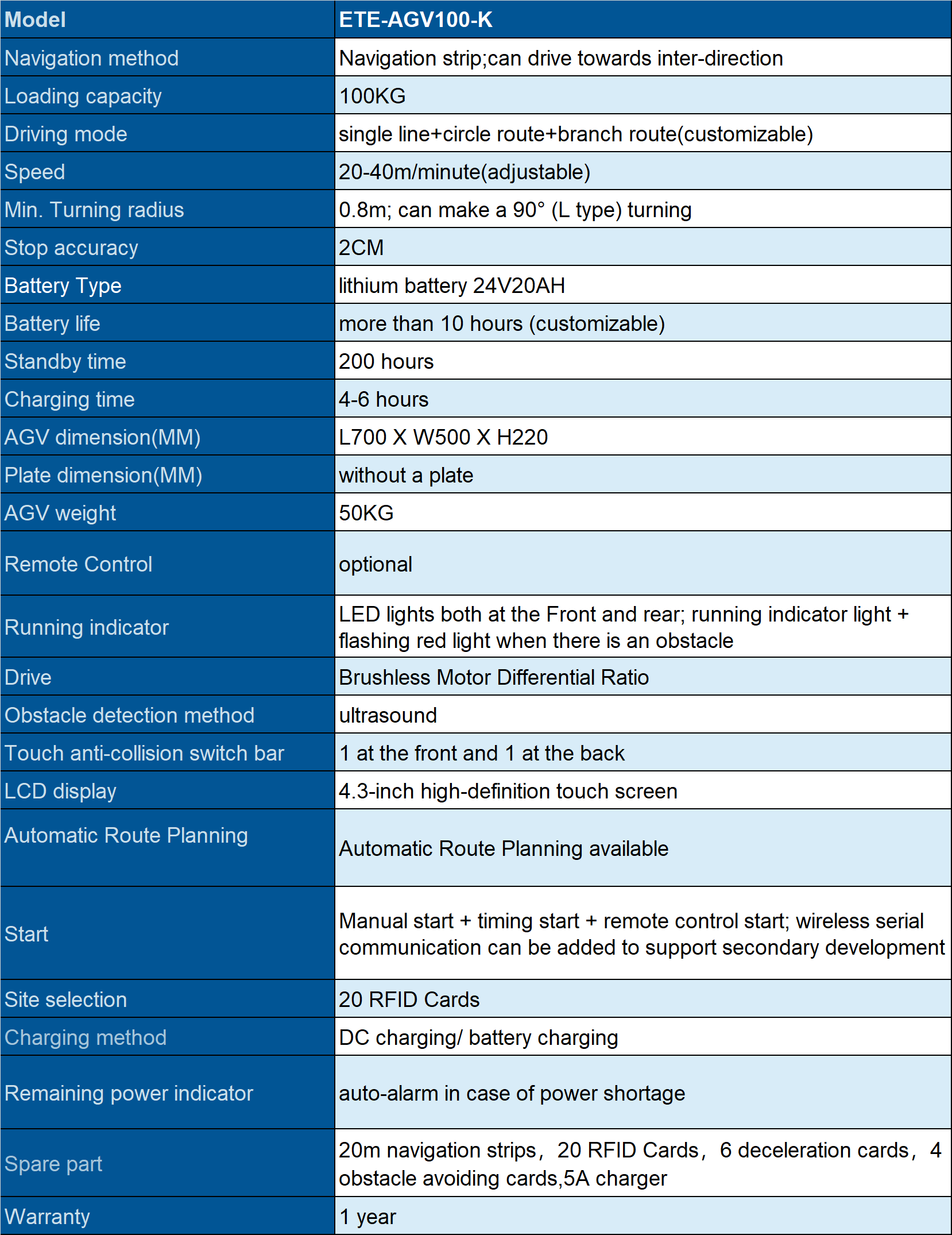

AGV Specification

Exceptional Load Capacity and Configuration

- Superior Load Capacity: The AGV robot can operate under shelves, carrying a load of up to 100kg.Thus this makes it ideal for heavy material transport.

- Comprehensive Product Configuration: Each AGV is equipped with essential features, including:

- Lifting columns

- Ultrasonic obstacle sensors

- Emergency stop switches

- HD touch screens

- DC charging ports

- Start switches

- Operation indicator lights

- Safety collision switches

Complimentary Accessories with Purchase

When you purchase our AGV robot, you will receive a free accessory package that includes:

- Magnetic navigation strips

- RFID site cards

- A 5A charger

- A remote control

Transforming the Electronics Manufacturing Industry

The AGV Robot has revolutionized logistics, warehousing, and production lines in the electronics manufacturing industry. Our AGVs have empowered numerous customers to establish automated and intelligent production facilities. For instance, AGV transport vehicles efficiently handle material transportation within electronic factory warehouses, significantly reducing labor costs. Additionally, AGVs replace manual labor on production lines, seamlessly shuttling soldering fixtures back and forth, thereby enhancing operational efficiency.

Conclusion

Investing in the AGV Robot Wave Soldering Pallet is a strategic move towards automating your SMT production line. With its advanced capabilities, this AGV robot will enhance your operational efficiency, safety, and adaptability in a fast-paced manufacturing environment.

Contact us today to learn more about how our AGV solutions can transform your production processes and boost your bottom line!