In the electronics manufacturing industry, the AGV Robot for SMT factory is a game-changer. This advanced automated guided vehicle enhances automation levels and significantly improves operational efficiency in SMT (Surface Mount Technology) facilities. With the AGV Robot, you can streamline material transport within your SMT warehouse and efficiently distribute SMT materials across various production lines.

Key Benefits of the AGV Robot for SMT Factory

- Efficient Material Transportation: The AGV Robot can navigate freely between different SMT production lines, facilitating the automated transport of materials and wave soldering pallets. This capability helps create an efficient pallet return system for your DIP insertion line.

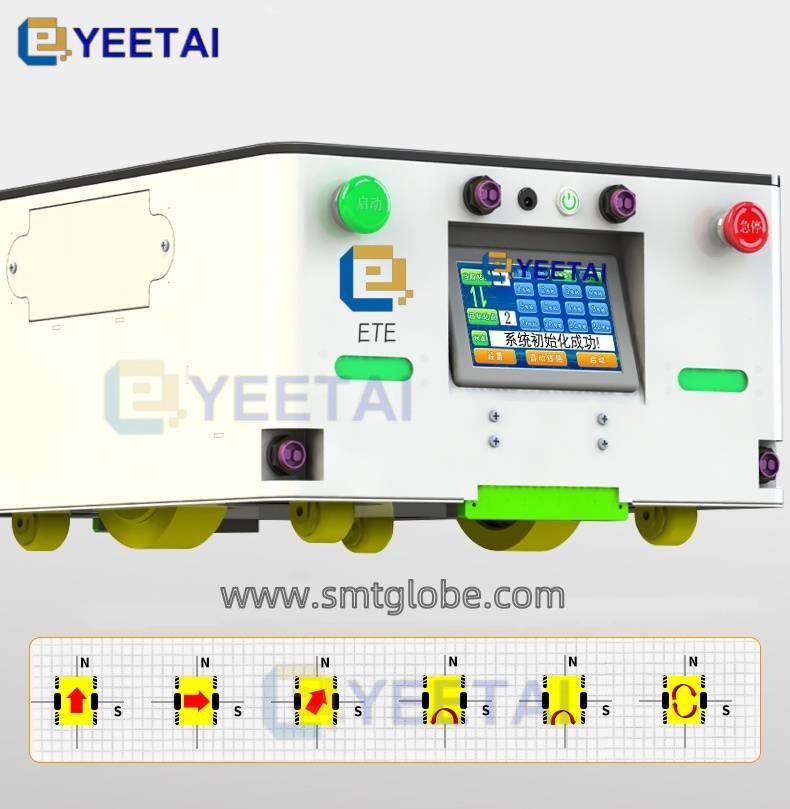

- Flexible Station Selection: Choose from 20 stations with independent stop settings and automatic route planning, allowing for customized operations tailored to your factory layout.

- Versatile Operating Modes: The AGV Robot offers several modes to suit your needs:

- Single Line Mode

- Loop Mode

- Branch Line Mode

- Off-Track Remote Control Mode

- User-Friendly Control Options:

- Computer Control: We provide free software support for computer control, enabling wireless serial communication via Bluetooth and support for secondary development.

- 15-Key Multifunction Remote Control: Easily control the AGV with 13 keys for station selection, start/stop functions, and unmanned remote control in all directions.

- Custom Mobile App: Develop a dedicated app to control the AGV’s movements to target stations and monitor its status, enabling off-track operation.

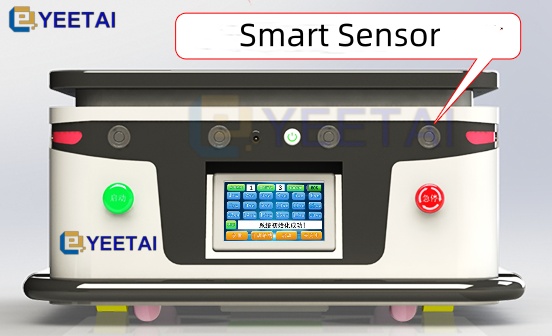

- Advanced Obstacle Recognition: The AGV Robot is equipped with sophisticated obstacle detection capabilities, ensuring safe navigation in busy factory environments.

Specification

Model ETE-AGV-760A Cart size (MM) Length 760 width 560 height 280 (car frame can be customized as required) Pallet size (MM) 760x500mm Maximum load Standard 100KG (can be customized within 1000KG) self-respect 52KG Navigation type Magnetic navigation two-way driving Drive mode Brushless motor, DIP differential ratio Driving logic RFID site identification, site selection, 20 stops driving mode Single line, loop line, branch line, derailment remote control Driving speed 0~40M/MIN(speed adjustable) Gradeability <=2 degrees Turning radius 0.8 meters (or 90-degree right-angle turn on the spot) Stopping accuracy Soil 5MM Charging time 5 hours Battery Type Management battery 252V15AH Standby time 200 hours Battery life =10H charging method Manual charging/replacing battery (automatic charging pile optional) Start mode Manual start + scheduled start + remote start, automatic operation can be set communication method Wireless serial communication can be added to support secondary development Human-machine page 4.3-inch high-definition touch display Obstacle detection method Ultrasonic radar sensors (4 at the front and rear) with adjustable sensing distance (lidar sensor is optional) Derailment remote control 15-key station remote control + derailment front and rear left and right operation Touch and impact protection Safety contact anti-collision beam Emergency stop and collision avoidance Front and rear emergency stop switches driving warning Front and rear LED lights: flashing green light when running + flashing red light when there are obstacles warranty period 12 months Chart 1# Specification about AGV robot ETE-AGV-760A

Features of the AGV Robot for SMT Factory

- High-Definition Touch Display: The AGV features a stylish 4.3-inch high-definition touch screen, providing an intuitive interface for easy operation.

- Durable Brushless Motor: Utilizes industrial-grade brushless reduction motors that are maintenance-free, durable, and cost-effective.

- Flexible Charging Options: Choose between manual charging or quick battery replacement, with an optional automatic wireless charging station.

Obstacle Detection Features

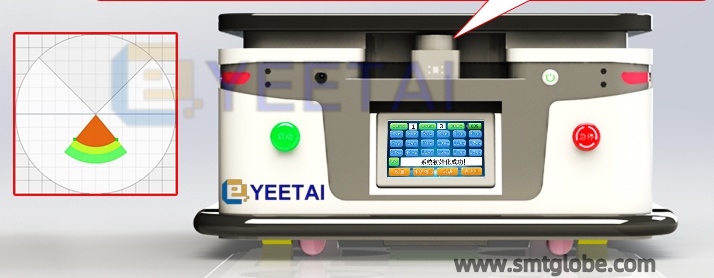

- Laser Radar Scanning:

- With a distance accuracy of ±30mm, the AGV can intelligently identify obstacles, automatically decelerate, and issue voice alerts with red light indicators.

- Ultrasonic Obstacle Sensors: (Four at the front and back)

- Caution Zone: Detects obstacles within a 1-meter range and slows down.

- Warning Zone: Detects obstacles within a 0.6-meter range and gradually stops.

- Emergency Stop Zone: Detects obstacles within a 0.15-meter range, triggering an immediate stop.

- Laser Radar Sensors: (One at the front and one at the back)

- Offers distance accuracy of ±30mm and angular resolution of 0.2°, scanning a 270-degree area to assess the distance to objects and detect obstacles.

Practical Applications of the AGV Robot for SMT Factory

- Bidirectional Straight Transport:

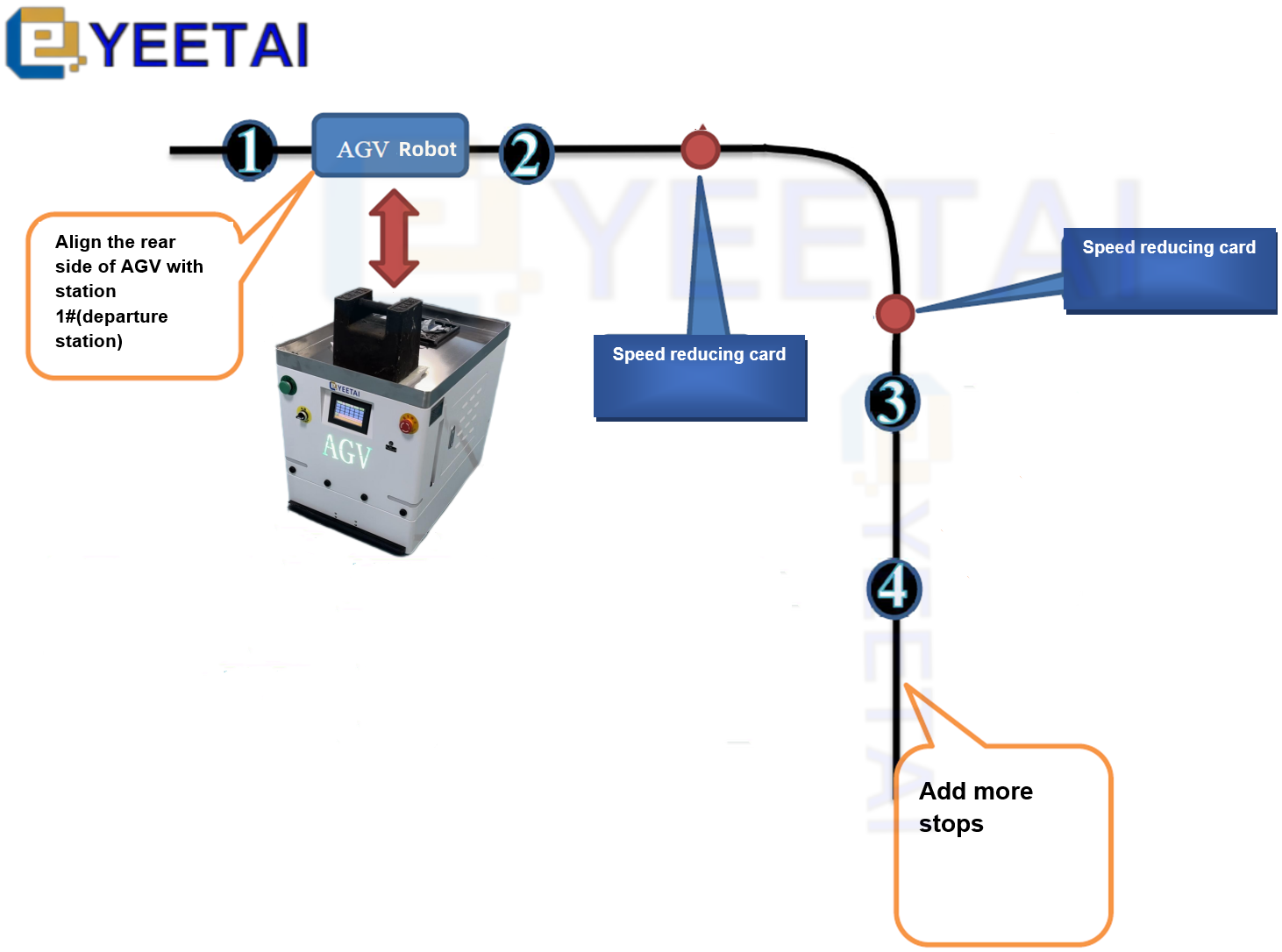

- Place RFID station cards along the installed navigation magnetic strips in ascending order, ensuring a minimum distance of 1 meter between stations.

- Bidirectional Curved Transport:

- When setting speeds above 80%, use deceleration markers placed 0.5 meters before and after turns to maintain stable navigation and prevent veering off the path.

- Loop Mode Transport:

- Create a closed-loop track with magnetic strips. The AGV will operate within this loop, with RFID station cards placed in ascending order and a minimum distance of 1 meter between stations.

- 90-Degree Right Angle Turns:

- The AGV can achieve automatic operation by setting the station sequence and stop duration, enhancing operational efficiency.

Conclusion

The AGV Robot for SMT factory is an essential tool for SMT facilities looking to enhance their operational efficiency and automation. By implementing this innovative solution, you can streamline material transportation, reduce labor costs, and improve overall productivity.

For more information on how the AGV Robot for SMT factory can transform your manufacturing process, contact us today!

Welcome to our factory to know more about SMT AGV robot.

Our company is dedicated to the development and manufacturing of intelligent sensor-guided AGV transport vehicles. We collaborate comprehensively with customers to provide effective solutions tailored to their needs, ultimately enhancing their production efficiency. Welcomed to our factory.