AGV Robot for PCB Moving: Enhance Efficiency in Electronic Manufacturing

Discover our AGV Robot, engineered for moving PCBs, wave soldering pallets, and PCB fixtures within electronic manufacturing environments. This advanced automated guided vehicle (AGV) provides a reliable solution for SMT (Surface Mount Technology) material handling and logistics in SMT warehouses. With its self-guided driving and cutting-edge lithium battery technology, our AGV offers cost-effective and efficient moving solutions for SMT production lines and PCB assembly. Explore our customizable AGVs to meet the specific needs of your smart factory.

Meet the AGV Robot for PCB moving ETE-AGV100-G: Your Ideal AGV Solution

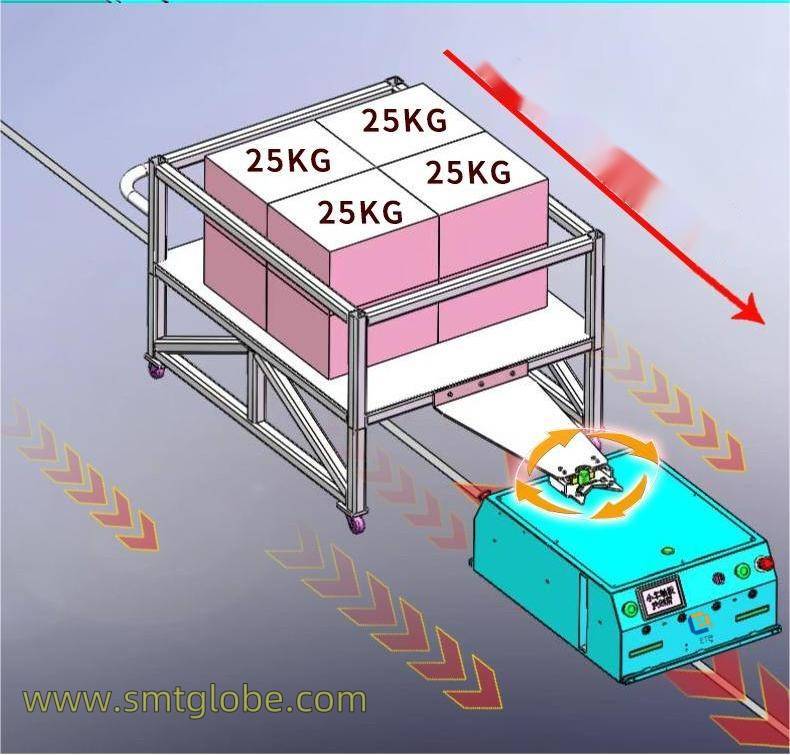

The ETE-AGV100-G is a state-of-the-art AGV robot designed for the seamless moving of wave soldering pallets and PCB fixtures. With a robust load capacity of 100 kg, this AGV features an autonomous driving system with ultrasonic obstacle detection, ensuring safe and efficient material moving within smart factories.

Key Features of the AGV Robot for PCB moving ETE-AGV100-G

- High Capacity for PCB Moving: Move wave soldering pallets and PCBs effectively.

- Automated Guided Vehicle for Production Lines: Optimizes workflow in wave soldering operations.

- Efficient SMT Warehouse Moving: Streamlines material movement in SMT environments.

- Self-Guided Navigation: Enhances operations within modern SMT factories.

- Intelligent System for Improved Logistics: Designed for efficient PCB handling in SMT production lines.

- Enhanced Safety Measures: Equipped with a battery low voltage alarm, ultrasonic sensors, an emergency stop switch, and multi-site selection capabilities.

- Strong Load-Bearing Capacity: Operates effectively under shelves with a capacity of up to 100 kg.

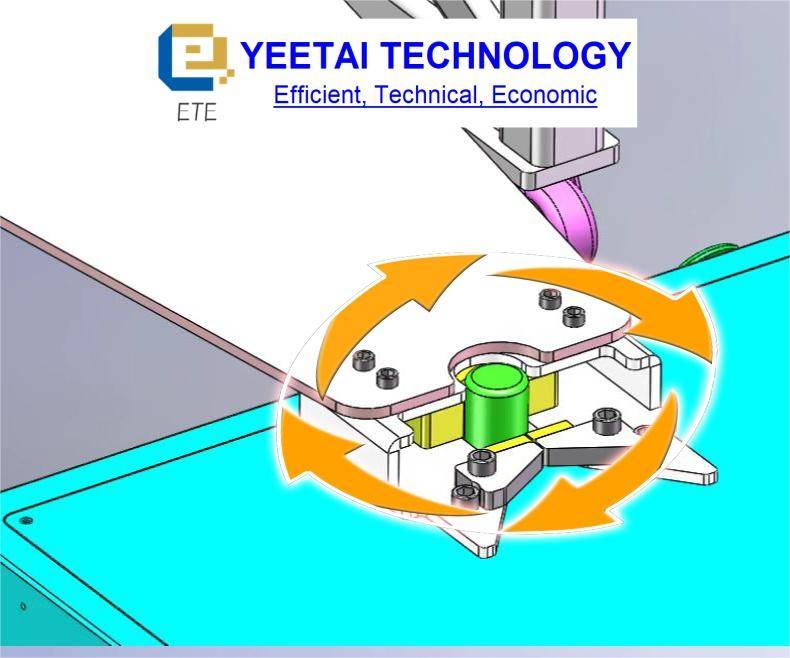

- Comprehensive Product Configuration: Features include a lifting column, ultrasonic sensors for obstacle detection, an emergency stop switch, a high-definition touchscreen, a DC charging port, a start switch, and an operation indicator light.

- Long Battery Life: Powered by a high-capacity lithium battery, the AGV can operate for up to 10 hours continuously. Custom battery capacities are available.

- Flexible Charging Methods: Charge the AGV directly or remove the battery for separate charging.

- Automatic Charging Functionality: Optional automated charging dock available for hassle-free operations.

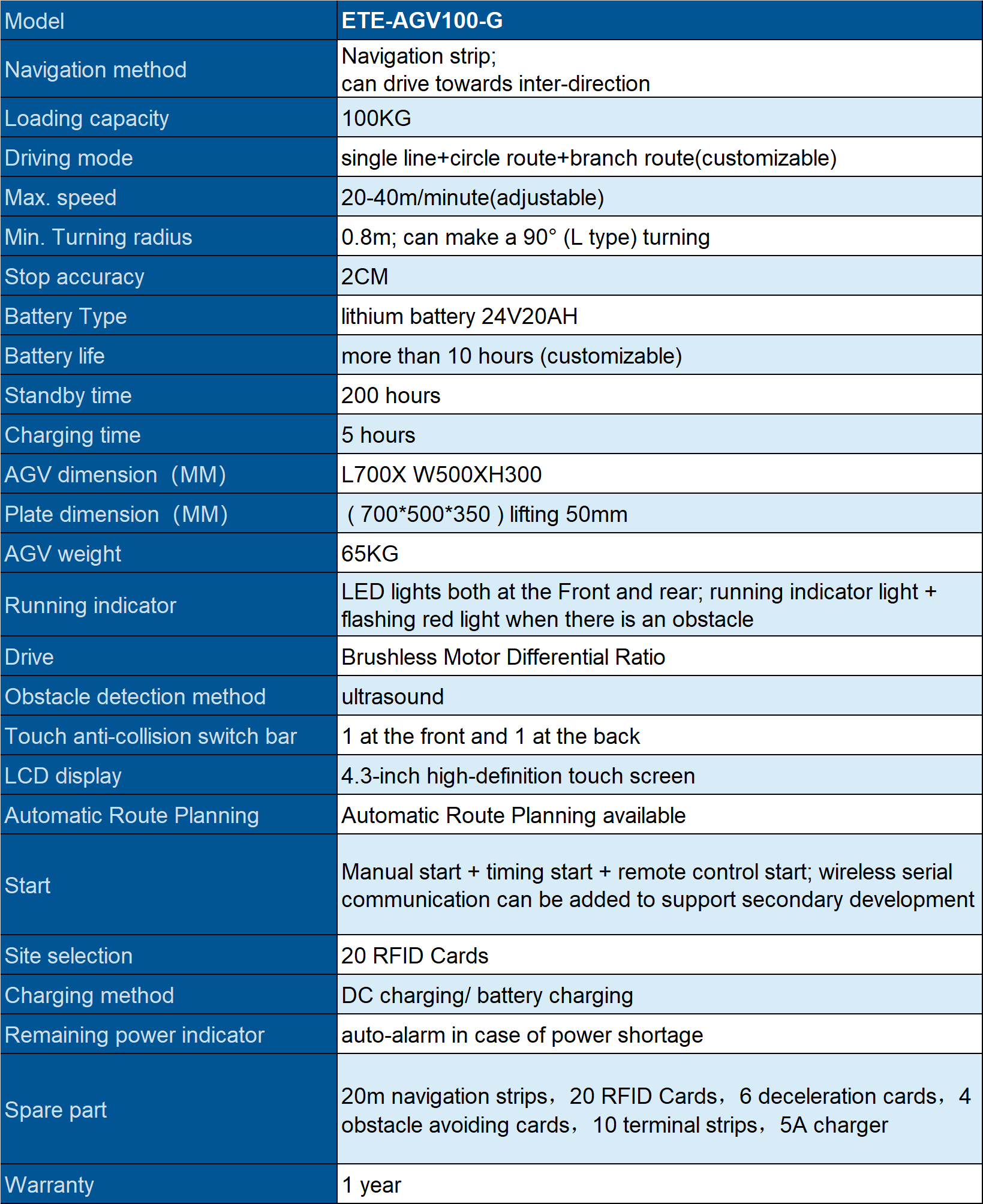

Specification

How the AGV Robot Operates

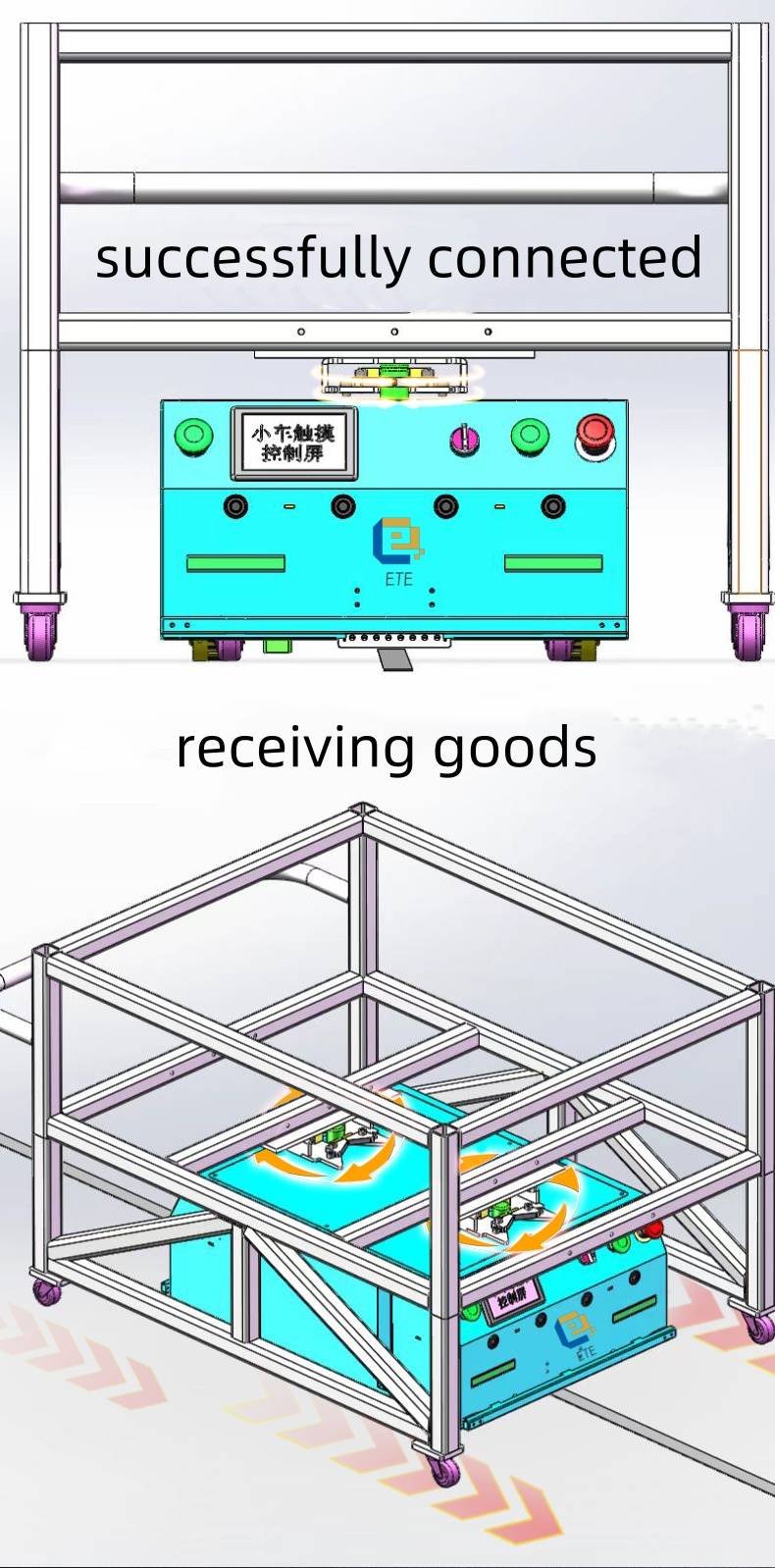

Upon receiving material handling instructions, the AGV Robot’s control system calculates, analyzes, and plans the optimal travel route based on a stored operational map and the current position of the AGV. It autonomously manages its movement and steering, enabling precise navigation.

When the AGV reaches the designated loading position, its material handling mechanism engages to ensure accurate loading. After loading, the AGV navigates to the unloading point, stopping precisely to unload. The handling mechanism completes the unloading process and reports the vehicle’s status to the control system.

Commitment to Innovation and Excellence

Our company is dedicated to developing innovative, intelligent, sensor-guided AGV moving vehicles, tugger AGVs, and automated loading/unloading solutions. Through continuous technological advancement, we have assembled a highly skilled design team with extensive expertise in the field. We collaborate closely with customers to deliver tailored solutions that enhance production efficiency. Our goal is to provide robust technical support to a wide range of clients in the manufacturing industry.

Why Choose Our AGV Robot?

- Efficiency: Increase throughput and reduce labor costs in your production lines.

- Safety: Minimize accidents and injuries with advanced obstacle detection and safety features.

- Customization: Tailored solutions to meet unique operational requirements.

- Support: Comprehensive customer service and technical support.

If you’re looking to modernize your manufacturing operations with smart moving solutions, contact us today to learn more about our AGV robots and how they can revolutionize your manufacturing processes.