Our AGV robot for soldering pallet moving,ESD SMT magazine rack,PCB and PCB fixture.Our AGV robot offers automation for an electronic manufacturer. It is also a great helper for SMT material handling and SMT warehouse and logistic.With self-guided driving and advanced lithium battery technology, our AGV offers cost-saving and efficient transport solutions for SMT production lines and PCB assembly. Explore our customizable AGV for your smart factory needs.

At YEETAI, we specialize in innovative Automated Guided Vehicles (AGVs), and our ETE-AGV100 model is exceptionally suited for SMT (Surface Mount Technology) workshops, particularly for moving DIP (Dual In-line Package) solder pallets in wave soldering processes.

Key Features of the ETE-AGV100 AGV Robot for soldering pallet

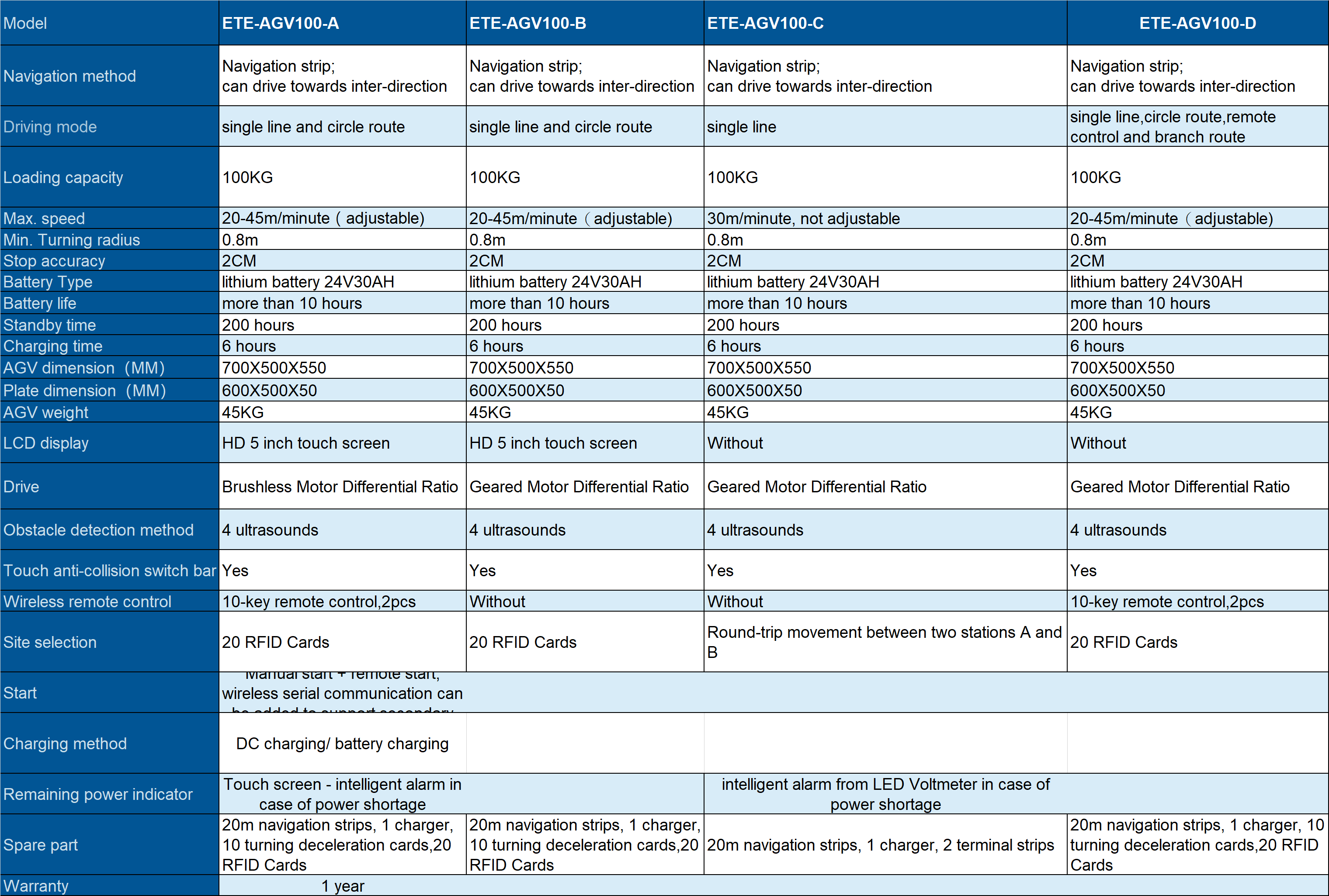

1. Intelligent Navigation and Control

- RFID Technology: Easily select operation sites with RFID cards, enhancing efficiency in logistics.

- High-Definition Touch Display: The upgraded screen allows for intuitive operation and supports remote selection of travel routes.

2. Flexible Operation Modes

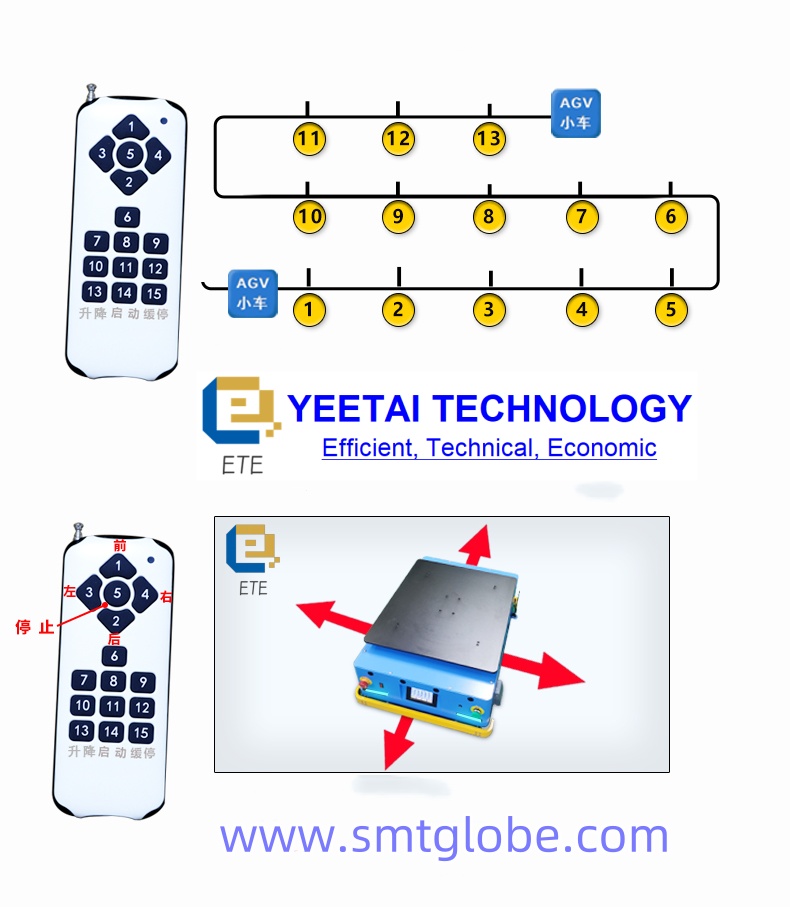

- Start Options: Choose between manual start, timer-controlled operation, or remote control, with customizable automatic running routes.

- Station Settings: Users can program up to 20 stations, with a simple interface allowing for easy adjustments to settings and dwell times at each station.

3. Robust Design and Performance

- Impressive Load Capacity: Our AGV can carry payloads of up to 100 kg, making it ideal for handling heavy wave soldering pallets.

- Powerful Lithium Battery: Equipped with a high-capacity lithium battery for long-lasting performance, reducing the need for frequent recharging.

- Advanced Motor Technology: The AGV features a state-of-the-art brushless DC motor for reliable and efficient operation.

Safety Features of AGV Robot for soldering pallet

The ETE-AGV100 is designed with numerous safety measures:

- Obstacle Detection System: With ultrasonic and infrared sensors, the AGV can autonomously detect obstacles. If an obstacle is within 40 cm, it will slow down and stop; within 1 meter, it emits an alarm before reducing speed.

- Emergency Stop Mechanism: The AGV will immediately stop upon contact with the anti-collision switch strips, enhancing workplace safety.

Included Accessories

The ETE-AGV100 comes with a comprehensive set of accessories:

- Wireless Remote Control

- Charger

- Magnetic Navigation Strips

- Obstacle and Speed Reduction Cards

- 20 RFID Site Cards

- Optional Wireless Charging Station

Specification

Operating Modes

The ETE-AGV100 offers three versatile operating modes:

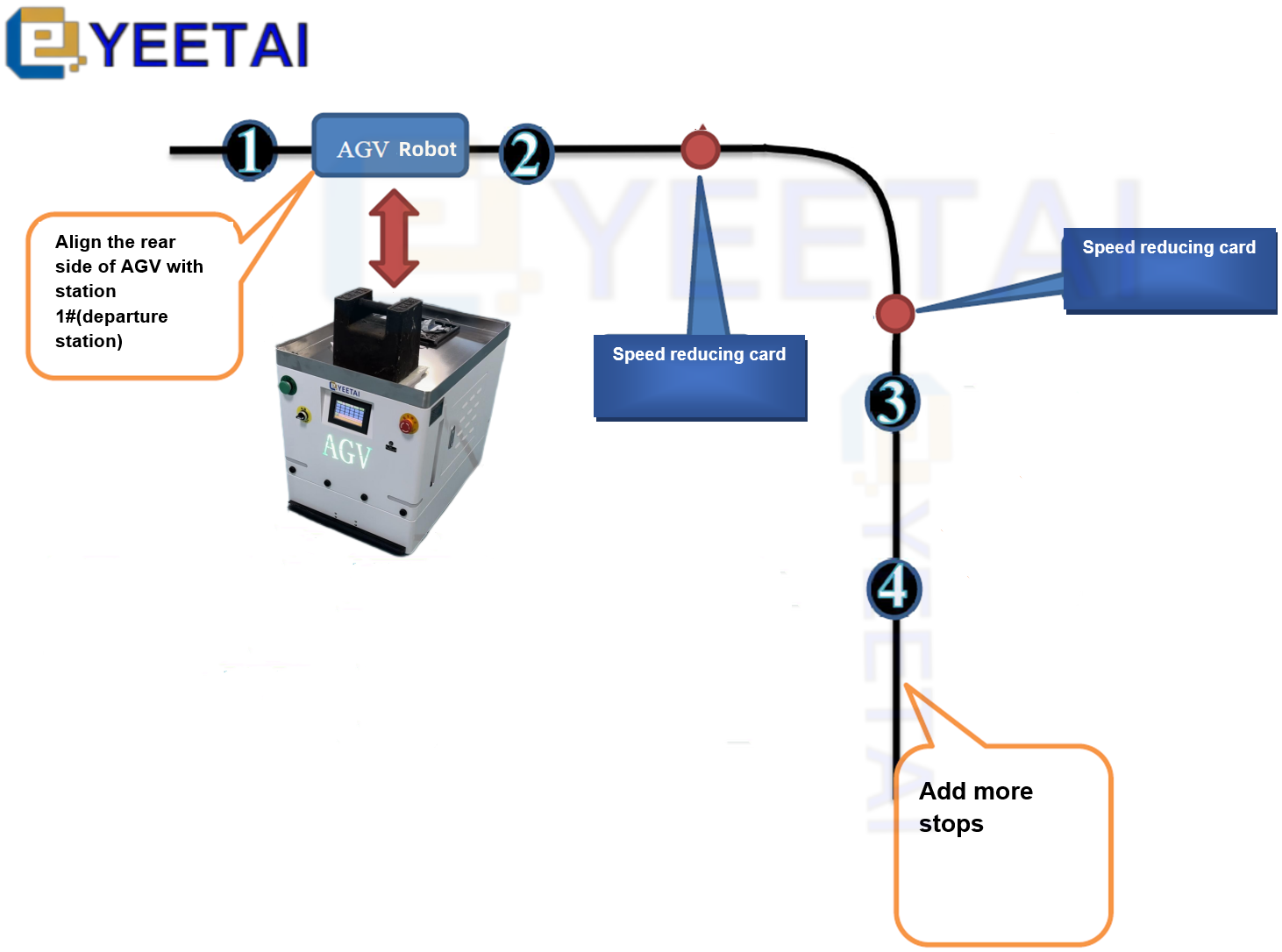

1. Automatic Sequential Route

Set up a sequence for the AGV to follow, with adjustable dwell times at each site.

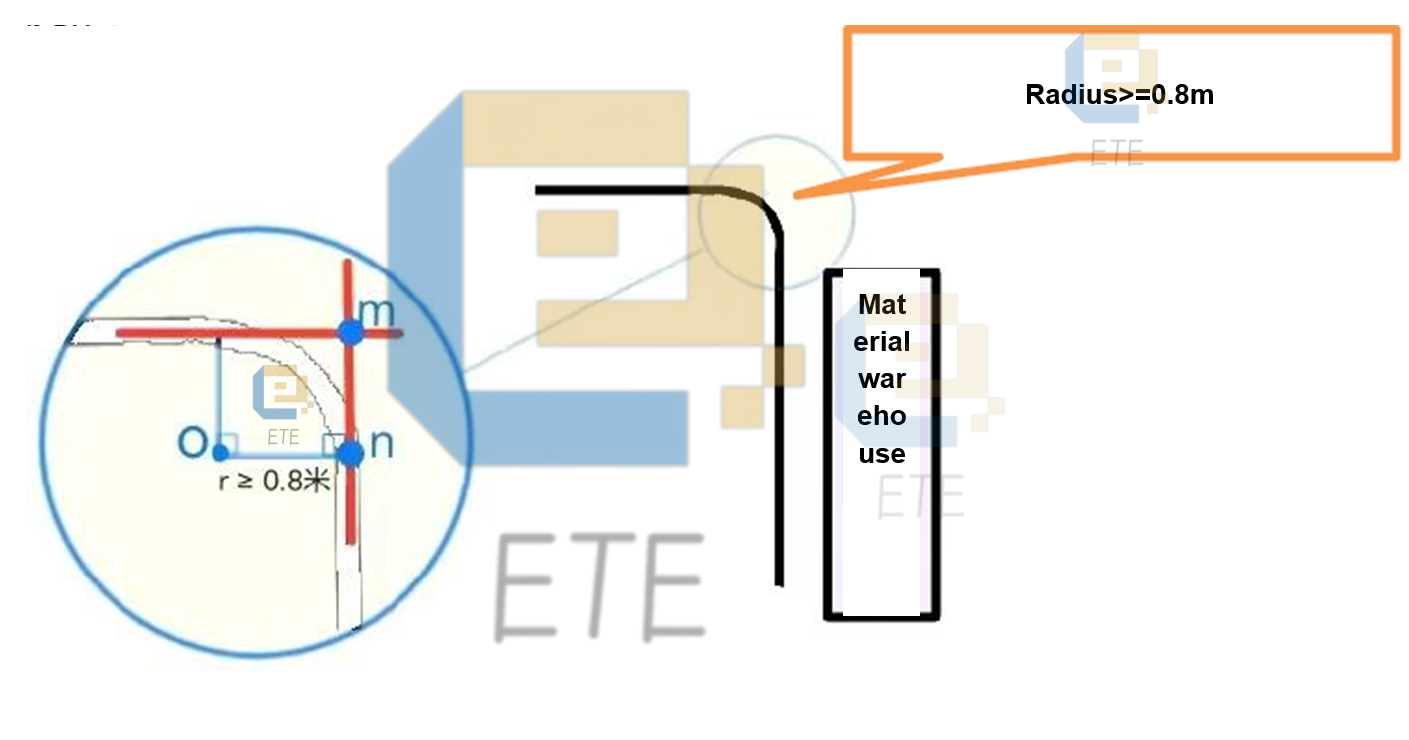

2. Loop Mode

Using magnetic strips, configure a closed-loop path for the AGV. The RFID station cards help the AGV navigate efficiently, calculating the best route automatically based on its current location.

3. Single Line Mode

For straightforward setups, stations can be arranged in a linear fashion, ensuring proper spacing for optimal navigation.

Conclusion

The ETE-AGV100 AGV Robot for soldering pallet by YEETAI is an essential tool for any assembly line requiring automation in handling wave soldering pallets. With its robust design, intelligent navigation system, and comprehensive safety features, this AGV significantly enhances efficiency while ensuring safety in the workplace.

For more information on how the ETE-AGV100 can improve your SMT production line, contact us today! Or find more models in our YouTube channel.