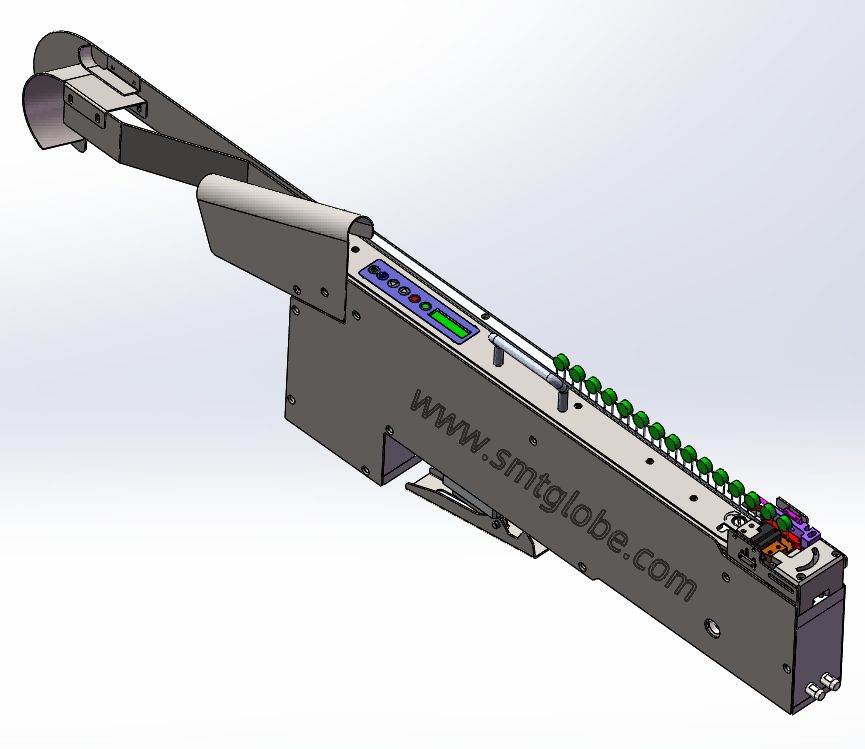

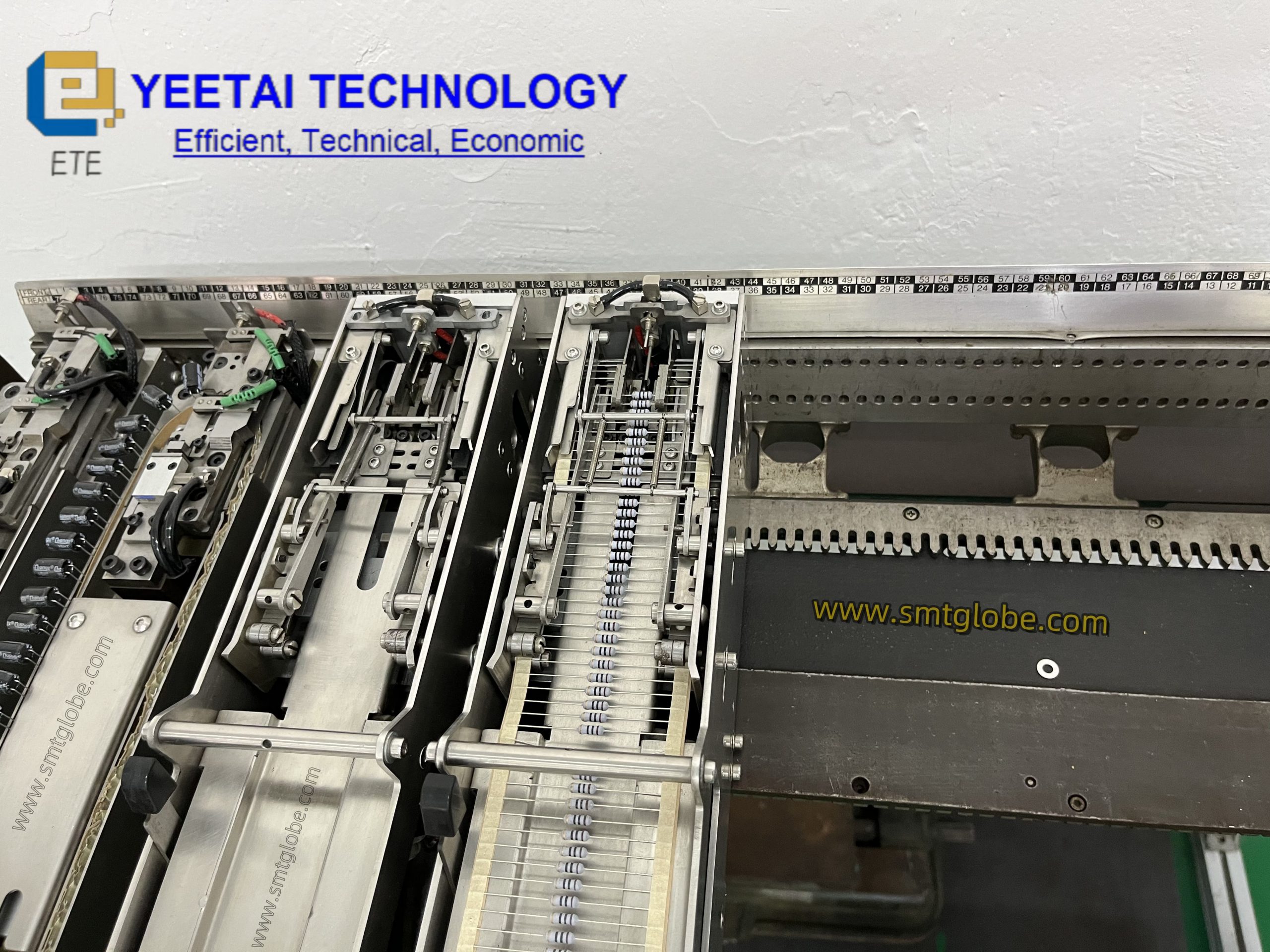

Tape feeders are specialized feeders designed for handling tape-reel components, commonly used in surface mount technology (SMT) and through-hole assembly machines. These feeders are compatible with materials such as capacitors, LEDs, and other electronic components. Tape feeders offer strong versatility, fast feeding speeds, high work efficiency, and low maintenance costs. Today, we’ll explore the key functions and advantages of tape feeders.

Advantages of Tape Feeders

- High-Speed and Accurate Feeding

Tape feeders use a combination of motors, ratchets, and photoelectric sensors for high-speed feeding and precise positioning. They are designed to accommodate a pitch of 12.7mm in tape-reel materials, ensuring efficient operation during assembly processes. - Versatile Cutting Module

The cutting module of tape feeders can accommodate various pitch sizes, with a maximum pitch capability of up to 22.5mm. This adaptability makes the tape feeder suitable for a wider range of components without requiring significant modifications. - Integrated Waste Tape Cutting

Tape feeders feature a built-in cutting mechanism that slices waste tape directly on the feeder. This eliminates the need for additional cutting equipment, streamlining the material handling process and reducing overall equipment costs.

Functions of Tape Feeders

- Convenient Material Change

When it is necessary to switch materials, operators only need to replace the corresponding cutting module. The cutting module is designed as a single unit that can be easily detached and replaced, significantly reducing downtime and labor costs. - Easy Integration

Tape feeders come with integrated communication and air supply systems compatible with pick-and-place machines. This feature allows for quick and seamless integration into the main assembly system, simplifying setup and improving operational efficiency.

Conclusion

Tape feeders are an essential component in modern electronics manufacturing, providing flexibility and efficiency in handling a variety of components. Their ability to facilitate rapid material changes, coupled with high-speed feeding and integrated waste management, makes them highly valuable in today’s fast-paced production environments. As the demand for efficient and reliable manufacturing processes continues to grow, tape feeders will play an increasingly vital role in the success of electronics assembly operations.

At YEETAI, we produce all kinds of feeder to upgrade SMT machines.