90 Degree Turning Conveyor: Flexible Solution for PCB Handling

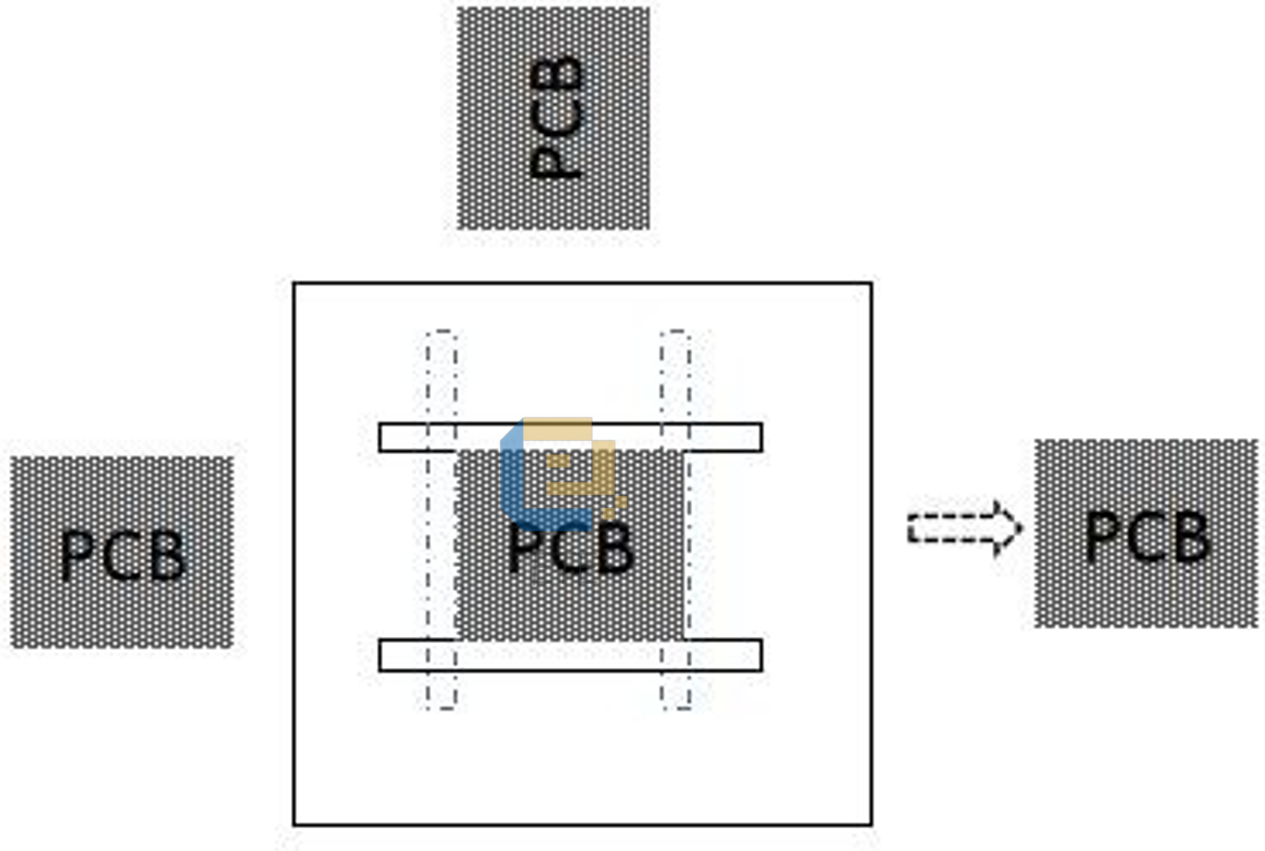

The 90 Degree Turning Conveyor provides exceptional flexibility by redirecting PCBs (Printed Circuit Boards) within production lines. It is helpful especially in L or U-shaped SMT (Surface Mount Technology) assembly setups. This conveyor enhances the adaptability of your assembly processes with its parallel and smooth width adjustment capabilities. It is designed for 90-degree lifting and turning operations. Suitable for the merging or splitting of boards. This innovative solution effectively addresses space limitations in SMT production lines. It enhances overall efficiency and optimizing factory space utilization.

Key Features of the 90 Degree Turning Conveyor:

- User-Friendly Control Panel: Equipped with a ‘soft-touch’ LED membrane control panel for easy operation.

- Safety Design: Enclosed structure with a built-in torque limiter ensures a high level of safety during operation.

- Convenient Maintenance: You can open the top cover for easy access. Convenient for maintenance and hardware handling.

- Adjustable Width: Features parallel and smooth width adjustment using a lead screw for customization to different PCB sizes.

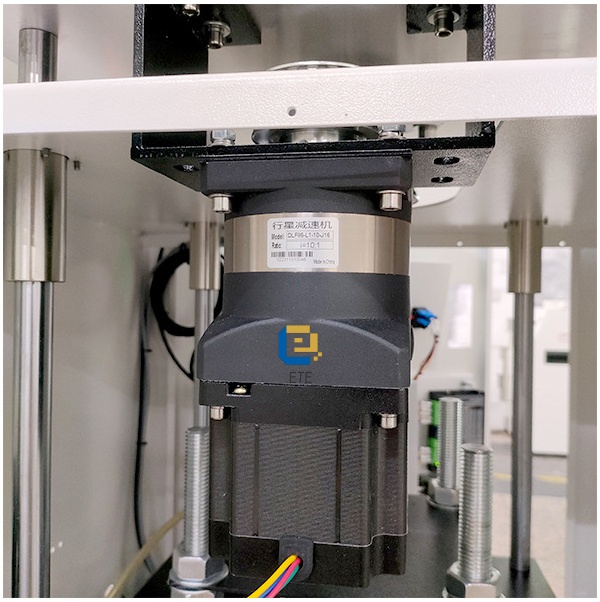

- Precise Scaling: Comes with a retractable motor for steady and precise scaling. It minimizes transmission clearance between conveyors.

- Custom Sizes: Different sizes are available upon request to suit specific production needs.

- Adjustable PCB Traffic Flow: PCB traffic can be adjusted for optimized handling within the production line.

- SMEMA Compatibility: The conveyor is compatible with the SMEMA interface for seamless integration with other equipment in the production line.

- Two Operational Modes: Offers both a 90-degree turning mode and a straight-through mode to increase flexibility and efficiency in production processes.

- Intelligent Touch Screen: The user-friendly touch screen interface simplifies operation and enhances the user experience, contributing to smooth workflow management.

- Stable Turning Speed: Adjustable turning speed ensures PCB boards remain stable during rotation, preventing slippage and optimizing production quality.

- Compact Design: The compact size of the conveyor occupies minimal floor space, making it suitable for various production environments with limited space availability.

Specification

| Model | ETO-300 | ETO-350 |

| PCB Size (L×W)~(L×W)mm | (50×50)~(450×300) | (50×50)~(450×350) |

| Machine Dimension (L×W×H) | 520x520x900 | 570x570x900 |

| Weight | Approx.110kg | 130kg |

| Cycle time | about 15 seconds |

| Power supply | 220-230V AC (user specified), single phase |

| Electrical load | Maximum 180 VA |

| Air pressure | 0.45-0.6Mpa |

| Air flow | Max. 30 liter/mm |

| Transport height | 900±20mm (or user specified) |

| Transport direction | Left → Right or Right → Left (optional) |

| Rail length | 600mm |

| PCB size | 50*50-450*300 |

| Machine rack | 610*800(Including operating surface 250mm)*950mm |

| Control mode | PLC + Touch Screen |

| Lifting device | Cylinder (optional motor) |

| Drive | Stepper motor + stepper driver |

| Rotate | Stepper motor + stepper driver |

| Weight | 90KG |